Concrete Expansion Joint Filler Board Road Construction

Product Details:

Concrete Expansion Joint Filler Board Road Construction Price And Quantity

- 1 Number

- 280.0 INR/Number

Product Description

Sure! Here's a clear and practical breakdown of the Expansion Joint Filler Board used in road construction:

Expansion Joint Filler Board for Road Construction

What Is It?

An Expansion Joint Filler Board is a compressible, pre-formed board installed between concrete slabs in roads and pavements to:

-

Absorb expansion and contraction of concrete

-

Prevent cracking, buckling, or blowouts

-

Maintain joint shape and function over time

Standard Specifications

| Specification | Typical Values |

|---|---|

| Material | Bitumen Impregnated Fiber Board (BIFB), or alternative: HDPE, XLPE, EVA Foam |

| Thickness | 12mm / 18mm / 25mm |

| Width (Height) | Matches the depth of the slab (100mm300mm) |

| Length | 1 meter / 2 meter boards |

| Density | 300500 kg/m (for BIFB) |

| Compression Recovery | 85% |

| Water Absorption | Low (especially in bituminous type) |

| Conformance | IRC:58, MoRTH Sec 602, ASTM D1751 |

Common Material Types

-

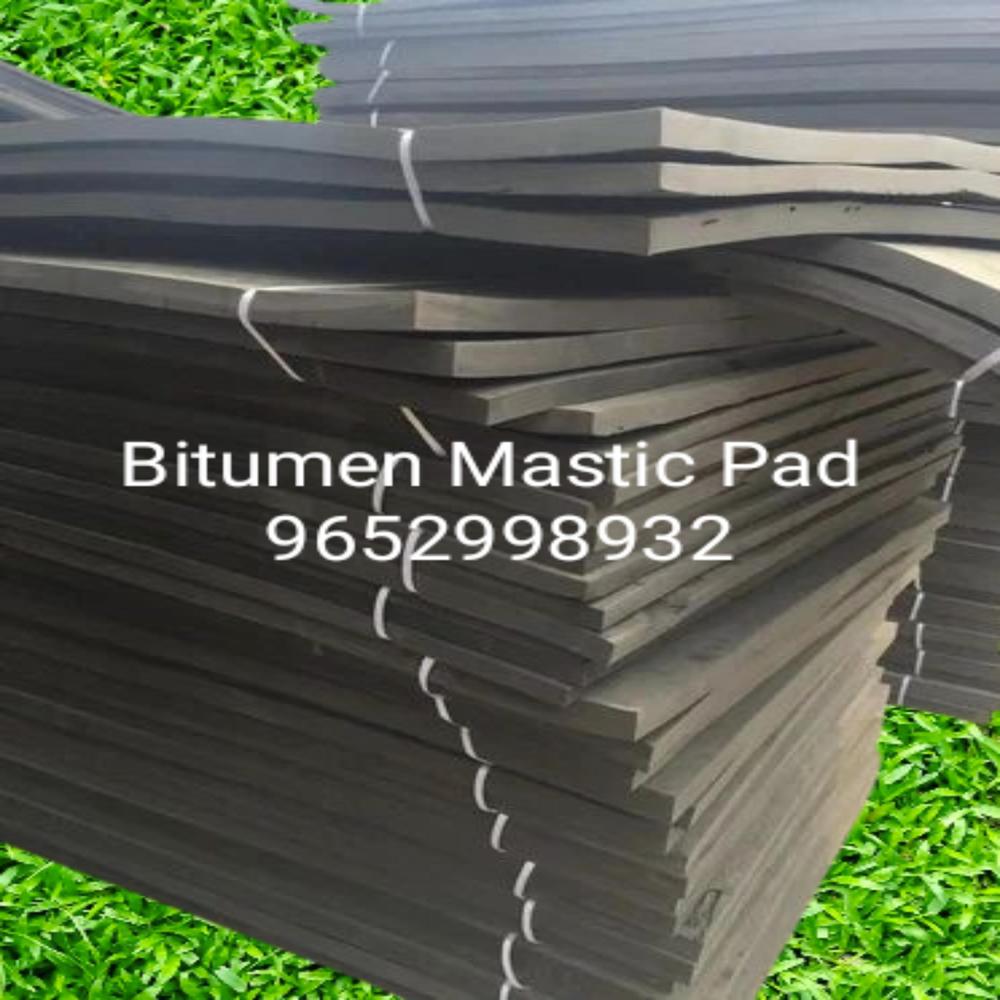

Bitumen Impregnated Fiber Board (BIFB) Most common

-

Strong, water-resistant, weatherproof

-

Good rebound capacity after compression

-

-

Cross-linked Polyethylene (XLPE) / EVA Foam

-

Lightweight, flexible, rot-proof

-

Excellent for tropical and coastal conditions

-

-

HD100 / HD200 Resin Board

-

High-strength resin-based boards for heavy-duty traffic areas

-

Installation Guidelines

-

Position the filler board vertically between concrete slab gaps before casting.

-

Ensure its flush with slab depth, leaving 10mm gap on top for joint sealant.

-

Fix it in place using nails, adhesives, or mechanical fasteners if needed.

-

After curing, fill the top gap with polysulphide or bitumen sealant.

Advantages

-

Accommodates thermal expansion and shrinkage

-

Prevents structural damage and water ingress

-

Chemically and weather resistant

-

Long-lasting and maintenance-free

-

Complies with road authority standards

Let me know if youd like:

-

A technical datasheet format

-

A BOQ line item for your tender

-

Or help comparing filler board types for a specific project (climate/load type/etc.)

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+