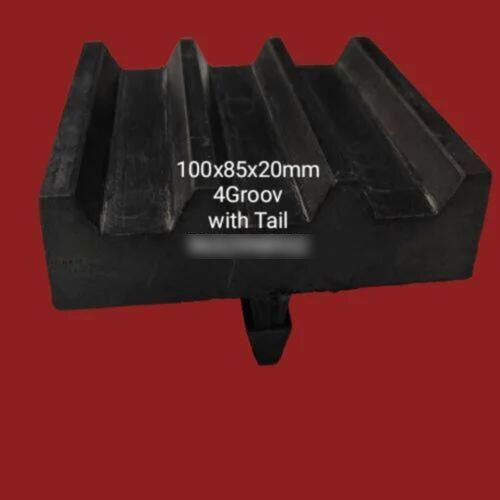

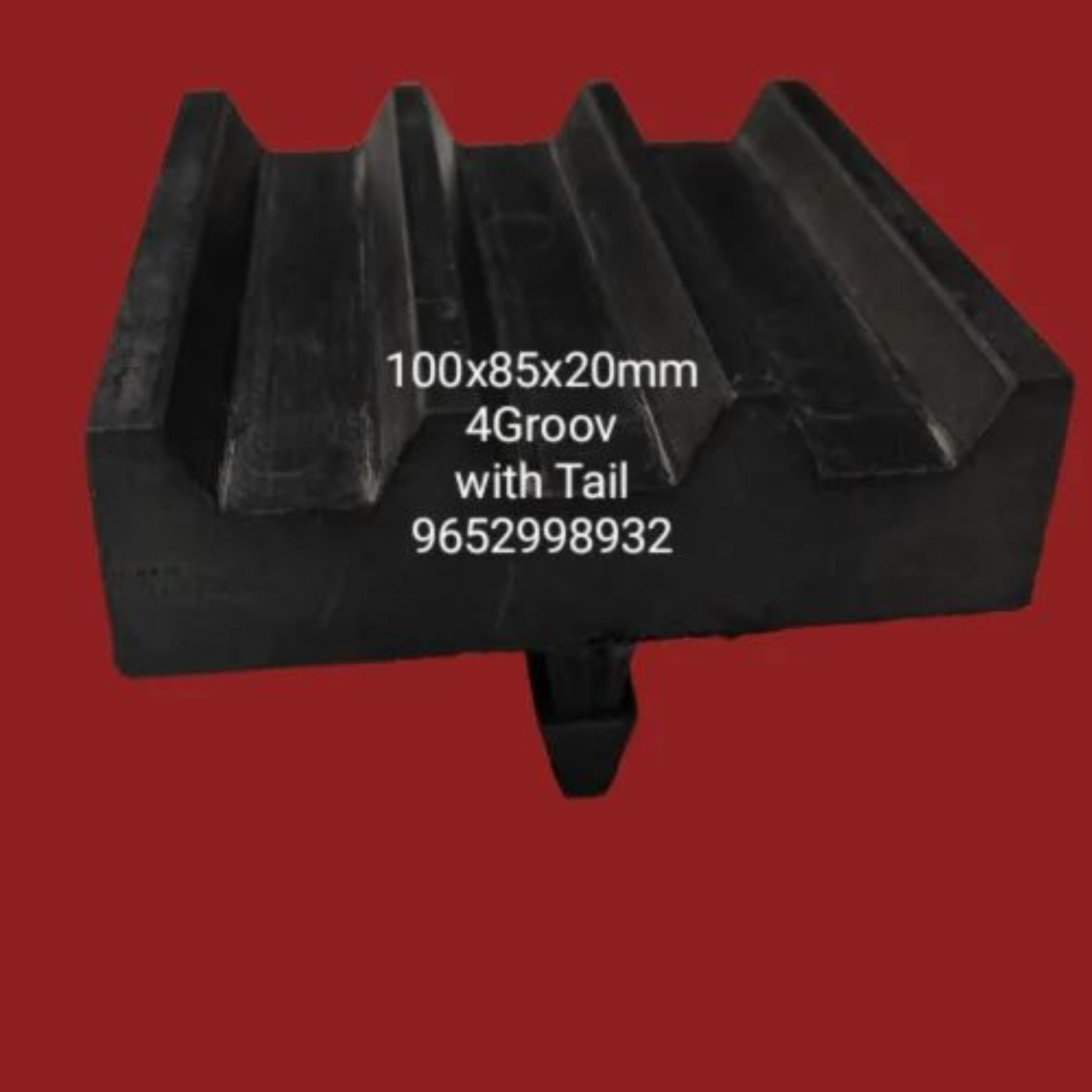

Groove Rubber Pad

Price 35.0 INR/ Piece

Groove Rubber Pad Specification

- Color

- Black

- Length

- Millimeter (mm)

- Tensile Strength

- 12 Megapascals (MPa )

- Product Type

- Groove Rubber Pad

- Diameter

- 1/2 Millimeter (mm)

- Thickness

- 20 to 25 Millimeter (mm)

- Feature

- The features of EPDM groove pads make them well-suited for various applications in construction, infrastructure, and engineering projects. Here are some key features of EPDM groove pads: 1. **Resilience**: EPDM groove pads exhibit excellent resilience, allowing them to recover their original shape after deformation. This resilience enables them to withstand repetitive loading, compression, and movement without permanent damage, ensuring long-term performance and durability. 2. **Flexibility**: EPDM groove pads are highly flexible, allowing them to accommodate movement, vibration, and thermal expansion in structures and mechanical systems. Their flexibility makes them suitable for use in expansion joints, bridge bearings, and other applications where dynamic movement is expected. 3. **Weather Resistance**: EPDM groove pads offer exceptional resistance to weathering, UV radiation, ozone exposure, and extreme temperatures. They maintain their mechanical properties and sealing effectiveness over a wide range of environmental conditions, making them ideal for outdoor applications. 4. **Chemical Resistance**: EPDM groove pads are resistant to a wide range of chemicals, oils, solvents, and acids, ensuring compatibility with various construction materials and environments. They provide reliable sealing and protection against corrosion, degradation, and chemical attack in aggressive industrial settings. 5. **Waterproofing**: EPDM groove pads possess excellent waterproofing properties, forming a tight seal to prevent water ingress and moisture penetration in building joints, pipeline supports, and other critical areas. They help maintain the integrity and longevity of structures by preventing water-related damage and deterioration. 6. **Noise and Vibration Reduction**: EPDM groove pads serve as effective vibration isolators and noise dampeners in machinery mounts, railway tracks, and building construction applications. They absorb and dissipate energy, reducing noise transmission, structural resonance, and equipment wear, improving overall performance and comfort. 7. **Non-Conductivity**: EPDM groove pads are non-conductive and electrically insulating, making them suitable for use in electrical installations, railway tracks, and other applications where electrical isolation is required. They help prevent electrical shock hazards and interference in sensitive equipment and systems. 8. **Ease of Installation**: EPDM groove pads are lightweight, easy to handle, and simple to install using standard tools and techniques. They can be cut, shaped, and bonded to various surfaces, reducing installation time and labor costs in construction and maintenance projects. Overall, the features of EPDM groove pads, including resilience, flexibility, weather resistance, chemical resistance, waterproofing, noise and vibration reduction, non-conductivity, and ease of installation, make them versatile and reliable solutions for a wide range of applications in diverse industries.

Groove Rubber Pad Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- mumbai

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 4 Days

- Packaging Details

- Packing with HDPE bag

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About Groove Rubber Pad

The features of EPDM groove pads make them well-suited for various applications in construction, infrastructure, and engineering projects. Here are some key features of EPDM groove pads:

1. Resilience EPDM groove pads exhibit excellent resilience, allowing them to recover their original shape after deformation. This resilience enables them to withstand repetitive loading, compression, and movement without permanent damage, ensuring long-term performance and durability.

2. Flexibility EPDM groove pads are highly flexible, allowing them to accommodate movement, vibration, and thermal expansion in structures and mechanical systems. Their flexibility makes them suitable for use in expansion joints, bridge bearings, and other applications where dynamic movement is expected.

3. Weather Resistance EPDM groove pads offer exceptional resistance to weathering, UV radiation, ozone exposure, and extreme temperatures. They maintain their mechanical properties and sealing effectiveness over a wide range of environmental conditions, making them ideal for outdoor applications.

4. Chemical Resistance EPDM groove pads are resistant to a wide range of chemicals, oils, solvents, and acids, ensuring compatibility with various construction materials and environments. They provide reliable sealing and protection against corrosion, degradation, and chemical attack in aggressive industrial settings.

5. Waterproofing EPDM groove pads possess excellent waterproofing properties, forming a tight seal to prevent water ingress and moisture penetration in building joints, pipeline supports, and other critical areas. They help maintain the integrity and longevity of structures by preventing water-related damage and deterioration.

6. Noise and Vibration Reduction EPDM groove pads serve as effective vibration isolators and noise dampeners in machinery mounts, railway tracks, and building construction applications. They absorb and dissipate energy, reducing noise transmission, structural resonance, and equipment wear, improving overall performance and comfort.

7. Non-Conductivity EPDM groove pads are non-conductive and electrically insulating, making them suitable for use in electrical installations, railway tracks, and other applications where electrical isolation is required. They help prevent electrical shock hazards and interference in sensitive equipment and systems.

8. Ease of Installation EPDM groove pads are lightweight, easy to handle, and simple to install using standard tools and techniques. They can be cut, shaped, and bonded to various surfaces, reducing installation time and labor costs in construction and maintenance projects.

Overall, the features of EPDM groove pads, including resilience, flexibility, weather resistance, chemical resistance, waterproofing, noise and vibration reduction, non-conductivity, and ease of installation, make them versatile and reliable solutions for a wide range of applications in diverse industries.

Exceptional Performance and Versatility

EPDM groove rubber pads deliver resilience, chemical stability, flexibility, and outstanding weather resistance, making them suitable for demanding construction and engineering applications. Their ability to withstand mechanical stress and harsh environmental factors ensures reliability in key infrastructure such as bridges, machinery mounts, and expansion joints.

Reliable Waterproofing and Safety Features

With waterproofing capability and non-conductivity, these groove pads not only prevent moisture damage but also serve safely in environments where electrical insulation is critical. Their chemical resistance further enhances longevity when used in industrial and outdoor settings.

FAQs of Groove Rubber Pad:

Q: How do EPDM groove rubber pads benefit construction and infrastructure projects?

A: EPDM groove rubber pads provide critical benefits such as resilience under load, flexibility for dynamic structures, resistance to weather and chemicals, reliable waterproofing, and noise reduction. These qualities make them ideal for protecting structural joints, ensuring longevity, and maintaining performance under variable environmental and mechanical stresses.Q: What is the installation process for Groove Rubber Pads, and are special tools required?

A: Installation of EPDM groove rubber pads is straightforwardpads are lightweight, can be cut or shaped as needed, and are easily bonded or fitted using conventional tools. No specialized equipment is required, reducing labor time and facilitating faster project completion.Q: In which environments and applications are these groove rubber pads most suitable?

A: These pads excel in outdoor and industrial environments such as building expansion joints, pipelines, machinery bases, railway tracks, and electrical installations. Their durability under exposure to UV, ozone, chemicals, and moisture enables reliable performance in diverse and challenging settings.Q: What measures make the Groove Rubber Pad resistant to weather and chemicals?

A: The use of EPDM rubber imparts incredible resistance to degradation from UV light, ozone, harsh temperatures, and a broad spectrum of chemicals, oils, and solvents. This ensures long-lasting sealing, protection, and stability even in aggressive or outdoor environments.Q: When should I choose an EPDM groove pad for my project?

A: EPDM groove pads are recommended when a project calls for high resilience, long-term durability, electrical insulation, noise or vibration reduction, or resistance to weathering and chemicals. Their versatility makes them advantageous for use in both new constructions and retrofit applications.Q: How does the pad contribute to noise and vibration reduction in machinery or structural systems?

A: The pad absorbs and dissipates vibrational energy and sound, which helps in minimizing noise transmission and reduces structural resonance. This characteristic not only improves comfort but also helps maintain equipment health by lessening wear and tear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

DURA BORD HD 100

Price 900.0 INR / Meter

Minimum Order Quantity : 500

Color : block

Size : 1/2

Surface Finish : Antiskid/ribbed

Usage & Applications : industial

Slurry Rubber Hose

Price 9000.0 INR / Number

Minimum Order Quantity : 1 Number

Color : Black with colored identification stripe

Size : 2 inches to 16 inches (or as specified)

Surface Finish : Smooth or cloth marked

Usage & Applications : Slurry, mud, grit and sand conveying in mining, industrial, dredging and construction sites

Plain Vibrating Rubber pad

Price 500.0 INR

Minimum Order Quantity : 1

Color : Black

Size : 100 mm x 100 mm

Surface Finish : Smooth, Nontextured

Usage & Applications : Vibration isolation in machinery, compressors, HVAC units, generators, and industrial equipment

INSULATING RUBBER MAT 1X2 MTR 2MM THICKNESS

Price 400.0 INR / Meter

Minimum Order Quantity : 1 Meter

Color : Black

Size : 1 meter x 2 meter

Surface Finish : Fine ribbed or checkered pattern

Usage & Applications : Used for providing insulation in electrical environments, control panels, substation flooring, and around electrical equipment to ensure safety against electric shocks.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS