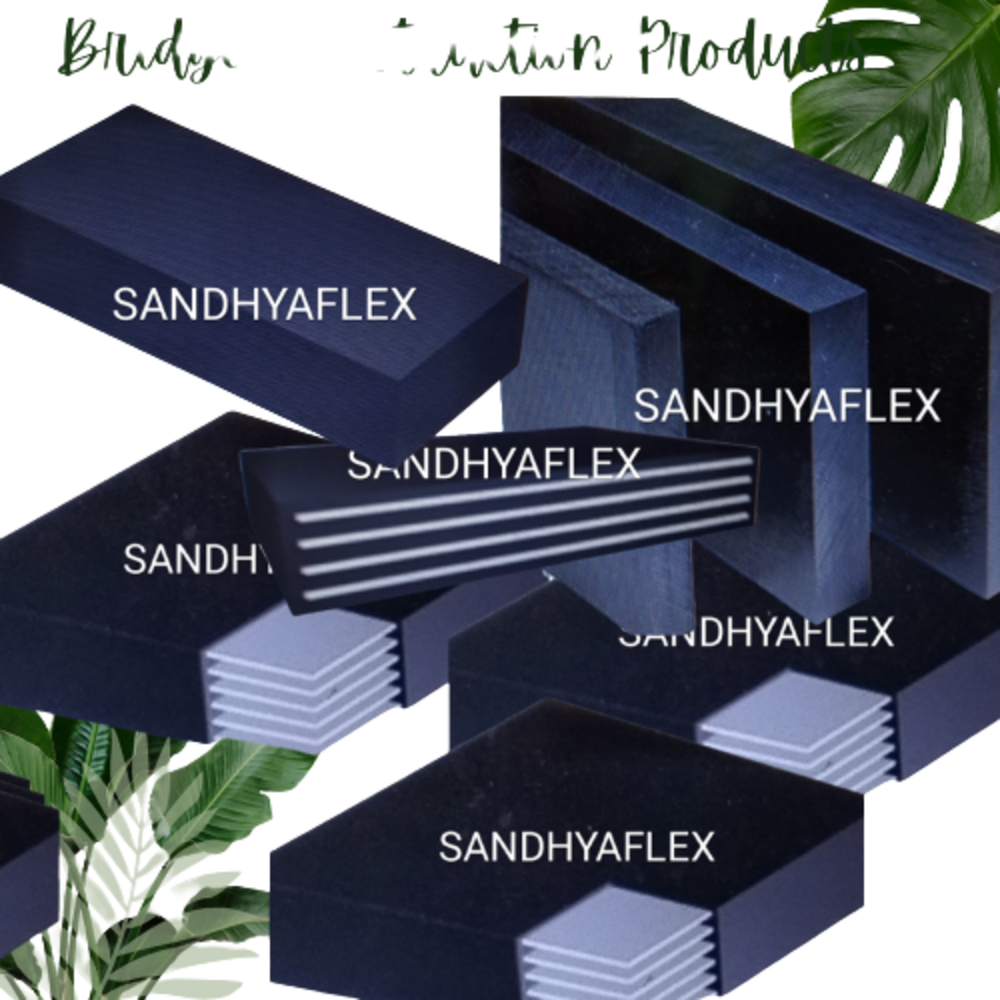

Bridge Construction Elastomeric Bearing

Price 3500 INR/ Piece

Bridge Construction Elastomeric Bearing Specification

- Usage

- Bridge Construction

- Size

- 22mm to 144m

- Material

- Rubber

- Product Type

- Bridge Construction Elastomeric Bearing

- Color

- Black

- Warranty

- 15 Years date of Manufacturing

Bridge Construction Elastomeric Bearing Trade Information

- Minimum Order Quantity

- 2000 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 25000 Pieces Per Day

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- Elastomeric bridge bearings are devices used in bridge construction and infrastructure to accommodate movements and rotations between different bridge components. These bearings are made from a type of synthetic rubber known as elastomer, which has excellent elasticity and resilience properties. The primary purpose of elastomeric bridge bearings is to distribute and transmit loads, such as the weight of the bridge itself, traffic loads, and environmental forces, while allowing for controlled movement and rotation. They provide flexibility and prevent the transfer of excessive stress to bridge components, thus protecting the structure from damage and ensuring its durability. Here are some key features and benefits of elastomeric bridge bearings: 1. Load Distribution: Elastomeric bearings can distribute loads over a larger surface area, reducing the stress concentration on specific bridge elements. They help prevent localized damage and premature wear. 2. Movement and Rotation: These bearings can accommodate horizontal and vertical movements, as well as rotations, caused by factors such as thermal expansion and contraction, traffic loads, and seismic activity. They allow the bridge components to adjust and move without causing excessive stress or damage. 3. Vibration Damping: Elastomeric materials have excellent vibration damping properties, reducing the transmission of vibrations caused by traffic or environmental factors. This helps improve ride comfort and reduces the potential for fatigue in the bridge structure. 4. Durability and Longevity: Elastomeric bearings are designed to withstand long-term exposure to environmental conditions, including temperature variations, moisture, and chemical exposure. They have a long service life and require minimal maintenance. 5. Cost-Effectiveness: Compared to alternative bearing systems, such as roller bearings, elastomeric bearings are often more cost-effective in terms of initial installation and long-term maintenance costs. It's important to note that elastomeric bridge bearings come in various shapes and designs to accommodate different bridge configurations and load requirements. These include laminated elastomeric bearings, pot bearings, and spherical bearings, among others. The specific type of bearing used depends on factors such as bridge design, expected movements, and load conditions. Overall, elastomeric bridge bearings play a crucial role in ensuring the structural integrity and functionality of bridges by allowing controlled movements and distributing loads effectively.

About Bridge Construction Elastomeric Bearing

Offering the finest Elastomeric Bridge Bearing, Sandhya Flex takes pleasure as a leading manufacturer of the products. We have segregated our infrastructure into several units with one of them as packaging unit. Here we meticulously pack our Elastomeric Bridge Bearing to ensure safe and secure deliverables. For the safe storage of the manufactured products, we have installed our facility equipped with all the modern amenities for absolute quality satisfaction.

The features of the elastomeric bridge bearing involve a strong design, simple installation and high quality. Also, it allows movement in all the directions you desire. Moreover, it finds it application in bridges, auditoriums, buildings and stadiums among others. They have exceptional tensile strength along with good elongation strength.

They are easy to install for various applications. Above all, they require less maintenance as well. They are precisely manufactured by specialists and experts as per the national and international norms and standards. Also, we use premium quality raw material to manufacture these elastomeric bridge bearing which are sourced from reliable vendors. Further, we assure the best quality, superior performing, durable and energy-efficient elastomeric bridge bearing which you can get from Sandhya Flex at competitive prices in the market.

Robust Support for Bridge Structures

Bridge Construction Elastomeric Bearings serve as a vital component in modern bridges, absorbing movement and distributing loads for optimum performance. Their advanced rubber composition ensures durability and adaptability, making them ideal for structures exposed to fluctuating loads and environmental conditions.

Wide Range of Sizes for Diverse Projects

Our elastomeric bearings come in an extensive range of sizes, starting from 22mm up to an impressive 144 meters. This versatility allows project engineers and contractors to find the perfect fit for nearly any bridge construction scenario, whether it's a small overpass or a large-scale infrastructure project.

FAQ's of Bridge Construction Elastomeric Bearing:

Q: How do elastomeric bearings benefit bridge construction?

A: Elastomeric bearings provide essential flexibility and load distribution, accommodating movements caused by traffic, temperature changes, and seismic activity. This helps minimize structural stress and extends the lifespan of the bridge.Q: What is the process for installing these rubber bridge bearings?

A: Installation typically involves placing the bearing between the bridge deck and substructure after ensuring surfaces are clean and level. Proper alignment and load testing are performed according to engineering specifications to guarantee optimal performance.Q: When is the ideal stage to install elastomeric bearings during bridge construction?

A: These bearings are usually installed after the substructure has been completed and before the bridge deck is set. This timing ensures stability and load transfer efficiency from the earliest stages of the bridge's use.Q: Where can I purchase these elastomeric bearings in India?

A: You can buy these bearings through authorized dealers, fabricators, manufacturers, producers, retailers, suppliers, traders, and wholesalers across India, ensuring easy access no matter your location or project requirements.Q: What are the recommended uses of these bearings?

A: Their primary application is in bridge construction, where they act as the interface between the superstructure and substructure, enabling controlled movement and effective load transfer.Q: What warranty coverage comes with the elastomeric bearings?

A: Every bearing includes a 15-year warranty starting from its manufacturing date, offering assurance against material and manufacturing defects over an extended service period.Q: How does the material composition benefit performance?

A: Manufactured from high-grade black rubber, these bearings offer excellent resilience, water resistance, and the capacity to absorb vibrations, making them ideal for demanding bridge construction environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elastomeric Bridge Bearing Category

Drainage spout

Price 1500 INR / Number

Minimum Order Quantity : 50

Material : Stainless Steel

Bore Size : 90 to 100mm

Lubrication Type : Other

Industrial Elastomeric Bridge Bearing

Price 6500.0 INR / Piece

Minimum Order Quantity : 1000 Pieces

Material : Rubber

Thickness : 96+5% Millimeter (mm)

P Series Pad

Price 250.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Sintered Bronze / Steel / Customized

Thickness : Standard / Custom

Bore Size : Customizable (as per requirement)

Lubrication Type : Other, Grease / Oil Lubrication

Rubber Elastomeric Bridge Bearing

Price 3500 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Rubber

Thickness : 22 to 144 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free