Industrial Rubber Beading

Price 135.0 INR/ Meter

Industrial Rubber Beading Specification

- Material

- EPDM / Natural / Synthetic rubber

- Ash %

- 0.5% Max

- Weight

- Variable, as per size

- Usage & Applications

- Sealing and insulation for doors, windows, automotive, and industrial machinery

- Temperature Resistance

- -40C to +120C

- Color

- Black

- Components

- Single or multi-component as required

- Tensile Strength

- 8 to 15.0 Megapascals (MPa )

- Water Absorption

- <2%

- Size

- Customizable as per requirements

- Density

- 1.15 Gram per cubic centimeter(g/cm3)

- Flame Resistance Level

- Optional flame-retardant grades

- Length

- 5 m to 50 m (Coil/Roll)

- Thermal Conductivity

- Low

- Nitrogen Content (%)

- 0.3% Max

- Resistance level

- High UV, ozone, weather resistance

- Product Type

- Rubber Beading

- Surface Finish

- Smooth or textured

- Volatile Matter (%)

- 1.0% Max

- Feature

- Weather Resistance

- Hardness

- 60 to 70 Shore A

- Diameter

- 6 mm to 25 mm

- Style

- Solid / Hollow types available

- Rubber Type

- EPDM, Nitrile, Natural Rubber

- Natural Rubber

- Available upon request

- Thickness

- 2 mm to 12 mm

- Width

- 6 mm to 40 mm

- Tolerance

- 0.5 mm

- Compression Ratio

- 25% to 35%

- Part Type

- Extruded rubber profile

- Trade Name

- Industrial Rubber Beading

- Finish

- Matte / Glossy

- Shape

- Rectangular / D-shape / Custom profiles

- Oil Resistance

- Medium (EPDM grade)

- Tear Strength

- 25 kN/m

- Installation Method

- Push fit / Adhesive backed / Channel fit

- Specific Gravity

- 1.2 ± 0.03

- Elongation at Break

- 250% to 350%

- Packing Type

- Rolls / Coils / Bundles

- Manufacturing Process

- Extrusion

Industrial Rubber Beading Trade Information

- Minimum Order Quantity

- 100 Meter

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 2000 Per Day

- Delivery Time

- 4 Days

- Sample Available

- Yes

- Packaging Details

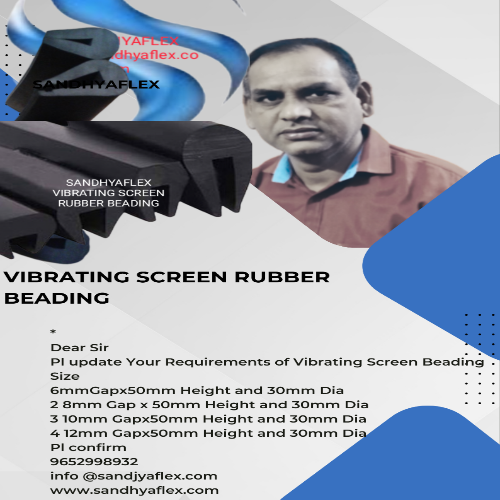

- packing in Coil 25 Mtr /Coil Export Packing Dimension in CBM Vibrating Screen Rubber Beading Color Block S No Dimension Weight/mtr Packing in / Roll Weight Kg/Roll Length Width Height CBM 1 8mm Gap,32mm Dia Height 52mm 1.8kg 25Mtr 44 kg/Roll 0.625 0.625 0.200 0.0781 2 10mm Gap,32mm Dia Haight 52mm 1.75 kg 25 Mtr 43Kg/Roll 0.625 0.625 0.200 0.0781 3 12mm Gap,32mm Dia Haight 52mm 1.65 kg 25Mtr 41 Kg/Roll 0.625 0.625 0.200 0.0781 4 16mm Gap,32mm Dia Haight 52mm 1.6kg 25 Mtr 40kg/Roll 0.625 0.625 0.200 0.0781

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About Industrial Rubber Beading

Industrial Rubber Beading is widely used in vibrating screen to avoid metal to metal contact. It is highly acclaimed in the market for its immense impact strength, long lasting finish and thermal resistance. It is manufactured using supreme grade quality components that is sourced from reliable vendors of the market keeping in mind set industry norms. As we offer this in various sizes and dimensions, customers can buy this range of Industrial Rubber Beading from us at very affordable cost.

At Sandhya Flex, being a renowned manufactured and supplier of vibrating screen rubber beading, we offer the best one of all. Suitable for 10 mm and 12 mm thick supporting plates, they are precisely designed to provide the maximum support and high dampening capacity. When placed under the vibrating screens, they serve the function of a buffer that avoids contact metals. Moreover, it helps in increasing the lifespan of the vibrating screens from vibrations. It offers immense strength alongside being long-lasting and adaptability to weather conditions.

It finds its application in automotive industries, metal industries and crusher vibrating screens. The offerings are rigorously checked and tested by our quality controllers to ensure high-quality and finest performance. Moreover, they have superior heat aging property while having the ability to bear high impact, shock and vibration.

The vibrating screen rubber beading experiences great demand in construction, mining and metal industry to protect the crusher screen from the vibrations and shock during the work. They are available in different sizes. You can choose from them depending on your requirements and specifications. With its exceptional design and build-up, they provide resistance to acids, bases, weather changes, high and low temperatures, load and more.

Versatile Applications and Flexible Customization

Industrial Rubber Beading is engineered for sealing and insulation requirements across diverse sectors, from automotive to industrial machinery. Its adaptability in profiles, dimensions, and installation methods ensures seamless integration in various assembly lines. The option to choose between solid, hollow, rectangular, D-shape, or custom profiles means it can address specific project demands efficiently.

Robust Material Properties for Tough Environments

Manufactured through extrusion with EPDM, nitrile, or natural rubber, the beading delivers formidable resistance to UV, ozone, and weathering. It operates reliably within a temperature range of -40C to +120C. The tensile strength of 8 to 15 MPa, tear strength of 25 kN/m, and a hardness rating of 60 to 70 Shore A guarantee durability and consistent performance even in challenging conditions.

FAQs of Industrial Rubber Beading:

Q: How is Industrial Rubber Beading typically installed?

A: Industrial Rubber Beading can be installed using various methods like push fit, adhesive-backed application, or channel fitting. The appropriate method depends on the structure and specific application area, ensuring a secure and lasting seal.Q: What are the primary uses of Industrial Rubber Beading?

A: This rubber beading is mainly used for sealing and insulation in doors, windows, automotive assemblies, and industrial machinery. Its weather-resistant properties make it suitable for any environment where protection against water, dust, and air leakage is required.Q: What materials are available for Industrial Rubber Beading production?

A: The beading is manufactured using EPDM, nitrile, or natural rubber, with EPDM grade offering medium oil resistance and excellent UV, ozone, and weather resistance. Custom material selection can be accommodated upon request.Q: Where can Industrial Rubber Beading be used most effectively?

A: It is most effectively applied in automotive door and window frames, industrial equipment enclosures, and building construction for sealing gaps and providing insulation. Its customizable dimensions and profiles make it versatile for a range of environments.Q: What is the manufacturing process for Industrial Rubber Beading?

A: The primary manufacturing process is extrusion, which allows precise control over shape and size. Both single and multi-component profiles can be produced as per customer specifications.Q: What are the benefits of using this beading over traditional sealing materials?

A: Industrial Rubber Beading offers superior weather, UV, and ozone resistance, along with flexibility and durability. It provides reliable sealing performance and a longer operational lifespan under harsh environmental conditions compared to conventional materials.Q: When should flame-retardant or natural rubber variants be considered?

A: Flame-retardant grades are recommended where enhanced fire safety is essential, such as in transport or certain industrial settings. Natural rubber can be requested for applications that require specific material characteristics or where standard synthetic options are unsuitable.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

Conductive Rubber Sheet

Price 350 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Hardness : 605 Shore A

Material : EPDM, Silicon, or Natural Rubber with conductive fillers

Color : Black

Surface Finish : Smooth or Textured

Cuttles Rubber Bearing

Price 2500.0 INR / Number

Minimum Order Quantity : 1 Number

Hardness : 6070 Shore A

Material : Natural Rubber with metal/brass insert

Color : Black

Surface Finish : Smooth, PrecisionMachined

Rubber Buffer

Price 2700.0 INR

Minimum Order Quantity : 1

Hardness : 5580 Shore A

Material : Highgrade rubber (Natural/SBR/EPDM)

Color : Black

Surface Finish : Smooth moulded

Music Note Rubber Seal

Price 1500.0 INR / Meter

Minimum Order Quantity : 100

Hardness : 6 to 70 Shore A

Material : Rubber seals

Color : Black

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS