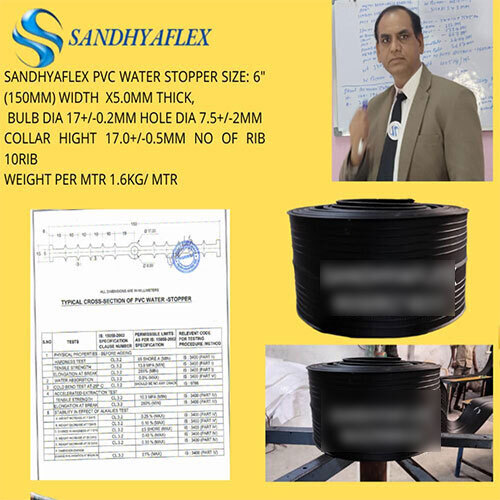

PVC Water Stopper product

Price 200.0 INR/ Meter

PVC Water Stopper product Specification

- Material

- PVC

- Type

- PVC Water Stopper product

- Thickness

- 3 mm Centimeter (cm)

- Application

- Tanks Dam Water Projects

- Hardness

- 65 Shore A

- Feature

- Waterproof

PVC Water Stopper product Trade Information

- Minimum Order Quantity

- 100 Meter

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Export Packing Date:02.09.2023 Dimension in CBM PVC Water Stopper with Center Bulb Each Roll 25Mtr SR No Dimension Length Width Height CBM Weight kg/Roll 1 150x5mm 0.625 0.625 0.150 0.059 40 2 150x6mm 0.625 0.625 0.150 0.059 45 3 150x8mm 0.625 0.625 0.150 0.059 55 4 200x8mm 0.625 0.625 0.200 0.059 60 5 200x10mm 0.65 0.65 0.200 0.078 64 6 225x5mm 0.625 0.625 0.23 0.090 65 7 225x6mm 0.625 0.625 0.230 0.090 70 8 225x8mm 0.65 0.65 0.230 0.097 90 9 225x10mm 0.65 0.65 0.230 0.097 100 10 240x8mm 0.65 0.650 0.240 0.104 110 11 240x10mm 0.650 0.650 0.240 0.104 125 12 250x8mm 0.675 0.675 0.250 0.114 95 13 250x10mm 0.675 0.675 0.250 0.114 115 14 300x6mm 0.700 0.700 0.300 0.147 95 15 300x8mm 0.725 0..725 0.300 0.158 115 16 300x10mm 0.750 0.750 0.300 0.169 140 17 300x12mm 0.775 0.775 0.300 0.18 140 18 300x15mm 0.800 0.800 0.300 0.192 160 Kiker Type 19 230x4mm 0.625 0.625 0.230 0.090 67 Dumbbell Type 20 230x8mm 0.650 0.650 0.230 0.097 87 21 230x10mm 0.650 0.650 0.230 0.097 100

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About PVC Water Stopper product

PVC water stoppers are devices used in construction joints and expansion joints of concrete structures to prevent the passage of water. These flexible PVC-based products create a watertight seal in joints, helping to protect structures from water infiltration and ensuring the integrity of the construction. Here are key features and uses of PVC water stoppers:

Key Features

1. Material

- PVC water stoppers are made from polyvinyl chloride (PVC), a synthetic plastic known for its flexibility, durability, and resistance to chemicals.

2. Flexibility

- PVC water stoppers are designed to be flexible, allowing them to accommodate movement and settlement in concrete structures without losing their effectiveness.

3. Ribbed or Dumbbell Shape

- The typical design of PVC water stoppers is either ribbed or dumbbell-shaped. The design helps enhance flexibility and provides a secure seal in joints.

4. Chemical Resistance

- PVC is inherently resistant to a variety of chemicals, ensuring that the water stopper remains effective even in environments with potential exposure to corrosive substances.

5. High Tensile Strength

- PVC water stoppers exhibit high tensile strength, which is crucial for withstanding the forces exerted on them during the expansion and contraction of concrete structures.

6. UV Resistance (for Exposed Applications)

- Some PVC water stoppers are formulated with UV-resistant additives to withstand prolonged exposure to sunlight when used in outdoor or exposed applications.

7. Ease of Installation

- PVC water stoppers are relatively easy to install. They are typically embedded in the concrete at the joints during the construction process.

8. Compliance Standards

- PVC water stoppers may need to comply with specific industry standards and regulations to ensure their quality and effectiveness in preventing water ingress.

Uses and Applications

1. Construction Joints

- PVC water stoppers are commonly used in construction joints of concrete structures to prevent water from entering the joints and potentially causing damage.

2. Expansion Joints

- In structures with expansion joints, PVC water stoppers are used to maintain the watertight integrity of the joints while accommodating movement.

3. Water Tanks

- PVC water stoppers find application in water tanks and reservoirs to create a watertight seal in joints, preventing leaks and ensuring the containment of water.

4. Basements and Foundations

- In below-grade structures, such as basements and foundations, PVC water stoppers are used to protect against water infiltration through joints.

5. Tunnels and Subway Construction

- PVC water stoppers are utilized in underground construction projects, including tunnels and subways, to prevent water ingress into the structures.

6. Dams and Canals

- Large concrete structures like dams and canals use PVC water stoppers to maintain the watertight integrity of joints and prevent seepage.

7. Swimming Pools

- PVC water stoppers are employed in the construction of swimming pools to create watertight seals around joints and connections.

8. Retaining Walls

- Retaining walls, especially those exposed to water, use PVC water stoppers to prevent water from penetrating the joints and causing erosion.

9. Bridges

- In bridge construction, PVC water stoppers are used in expansion joints to prevent water ingress and protect the structural integrity of the bridge.

10. Road Construction

- PVC water stoppers are applied in the construction of roads and highways to create watertight seals in joints, enhancing the durability of the structures.

PVC water stoppers play a vital role in maintaining the longevity and structural integrity of concrete constructions by preventing water infiltration, which can lead to deterioration and structural issues over time. The selection of the appropriate type and size of PVC water stopper depends on the specific application and construction requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Water Stopper Category

225mm PVC Water Stopper

Price 180.0 INR / Meter

Minimum Order Quantity : 1 Kilograms

Application : Industrial

Type : Water stopper

Surface Treatment : Polished

Feature : Waterproof, Smooth Surface, Weather Proof

225x6mm PVC Water Stopper

Price 180.0 INR / Meter

Minimum Order Quantity : 1 Kilograms

Application : Industrial

Type : Water stopper

Surface Treatment : Polished

Feature : Wear Resistant, Smooth Surface, Weather Proof, Waterproof

PVC Hand Rail 32mm

Price 70.0 INR

Minimum Order Quantity : 1 Meter

Application : Staircase, Balcony, Industrial Walkways, Safety Railing

Type : Hand Rail

Surface Treatment : Smooth finish

Feature : Other, Corrosion Resistant, Weather Proof, Durable, Low Maintenance, NonSlip Surface

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS