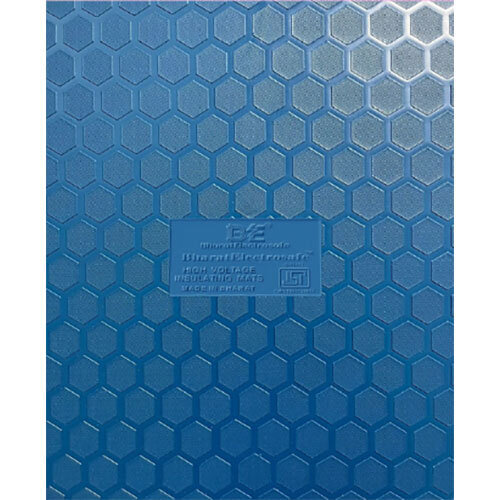

Electrical Insulating Rubber Mat

Price 525 INR/ Meter

Electrical Insulating Rubber Mat Specification

- Ash %

- Less than 1% (typical)

- Components

- Single Layered Rubber Compound

- Natural Rubber

- Yes contains natural rubber compound

- Width

- 1 meter

- Material

- High quality rubber

- Rubber Type

- Blend of Natural and Synthetic Rubber

- Size

- 1 meter x 2 meter, or as per requirement

- Compression Ratio

- Good compression set resistance

- Usage & Applications

- Electrical Insulation in Substations, Electrical Panels, Switchrooms, and Industrial Workshops

- Tolerance

- 5%

- Surface Finish

- Textured/Antiskid or Plain

- Temperature Resistance

- -25C to +55C

- Thickness

- 2 mm, 2.5 mm, 3 mm (as per IS 15652:2006)

- Style

- Plain or Anti-Skid Textured

- Water Absorption

- Low, <1% per ASTM D471

- Part Type

- Sheet Mat

- Resistance level

- Up to 11kV, 22kV, or 33kV (classified as per IS 15652:2006)

- Tensile Strength

- 15 N/mm minimum

- Density

- 1.5 Gram per cubic centimeter(g/cm3)

- Feature

- Weather Resistance

- Weight

- Approx. 6-12 kg/mat depending on thickness

- Thermal Conductivity

- Very Low (Excellent insulator)

- Color

- Black,Blue and Red

- Product Type

- Electrical Insulating Rubber Mat

- Flame Resistance Level

- Flame retardant as per IS 15652

- Hardness

- 55 to 60 Shore A

- Length

- 2 meter standard (custom available)

- Installation Type

- Loose Laid No fixing required

- Chemical Resistance

- Resistant to mild acids and alkalis

- Ozone Resistance

- Yes

- Insulation Resistance

- >100,000 Mega Ohms

- Electrical Breakdown Voltage

- Greater than 30kV for 3mm thickness

Electrical Insulating Rubber Mat Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 2000 Per Day

- Delivery Time

- 4 Days

About Electrical Insulating Rubber Mat

Electrical Insulating Rubber Mat is suitable for placing on the grounds in order to provide insulation to the electrical equipments for protecting from electric shock. It is highly praised in the market for features like resistance to electricity, durable finish and excellent finishing. Offered matting is manufactured by utilizing optimum quality rubber and the progressive techniques in adherence with the set industry standards. Clients can purchase this range of Electrical Insulating Rubber Mat at pocket friendly prices from us.

Reliable Electrical Safeguard

These rubber mats provide highly effective insulation for environments with up to 33kV electrical resistance, drastically lowering the risk of electrical shock. Their robust construction and adherence to IS 15652:2006 standards make them a trusted solution for a range of electrical installations.

Versatile Application & Adaptability

Suited for use in substations, switchrooms, high-voltage electrical panels, and industrial workshops, these mats come in a standard 1 meter by 2 meter size with options for custom dimensions. Available in both plain and anti-skid textured styles, they integrate seamlessly in diverse setups.

Durable & Weather-Resistant Design

Made from a quality blend of natural and synthetic rubber, the mats feature resistance against ozone, mild chemicals, and a wide temperature range. Their weather resistance ensures longevity even under harsh industrial conditions, while maintaining low water absorption and consistent performance.

FAQ's of Electrical Insulating Rubber Mat:

Q: How should the electrical insulating rubber mat be installed in high-voltage areas?

A: The rubber mat is designed for loose-laid installation, requiring no adhesives or fixings. Simply place the mat directly on the floor beneath electrical panels, switchgear, or control rooms, ensuring it covers the required area for maximum safety.Q: What are the main benefits of using this insulating mat in substations or industrial workshops?

A: The mat offers excellent electrical insulation (breakdown voltage >30kV at 3mm), high dielectric strength, and robust resistance to chemicals, ozone, and weather. This combination helps safeguard personnel from electrical shocks and ensures long-term durability in demanding environments.Q: When should these mats be replaced or inspected?

A: It is recommended to inspect the mats regularly for any visual damage, cracks, burns, or wear. While the mats are durable and weather-resistant, prompt replacement is needed if visible defects or reductions in insulation properties are detected, to maintain electrical safety standards.Q: Where can the electrical insulating rubber mats be effectively used?

A: These mats are best suited for use in substations, electrical panels, switchrooms, and industrial workshops where enhanced electrical insulation is required to protect operators from electric shocks.Q: What makes this mat chemically and environmentally resistant?

A: The mat is formulated with a blend of natural and synthetic rubber, granting it resistance to mild acids, alkalis, and ozone. This ensures reliable performance in environments exposed to chemicals and harsh weather conditions.Q: How does the anti-skid or plain surface finish impact usage?

A: Both plain and anti-skid textured options are available. Anti-skid textures enhance safety by reducing slip hazards, especially in areas prone to moisture or oil, while plain surfaces offer a smooth finish suitable for general use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

Sponge Rubber Beading

Minimum Order Quantity : 200

Color : Black (other colors available on request)

Product Type : Sponge Rubber Beading

Hardness : 1525 Shore A

Material : EPDM/Sponge Rubber/Natural Rubber

Export Quality Vibrating Screen Rubber Beading

Price 210.0 INR

Minimum Order Quantity : 1 Meter

Color : Black

Product Type : Vibrating Screen Rubber Beading

Hardness : 60 5 Shore A

Material : Natural Rubber, Synthetic rubber blends

Electrical Insulating Rubber Sheet 2mm

Price 440.0 INR

Minimum Order Quantity : 1 Meter

Color : Black

Product Type : Electrical Insulating Rubber Sheet

Hardness : 65 5 Shore A

Material : Highquality natural rubber compound

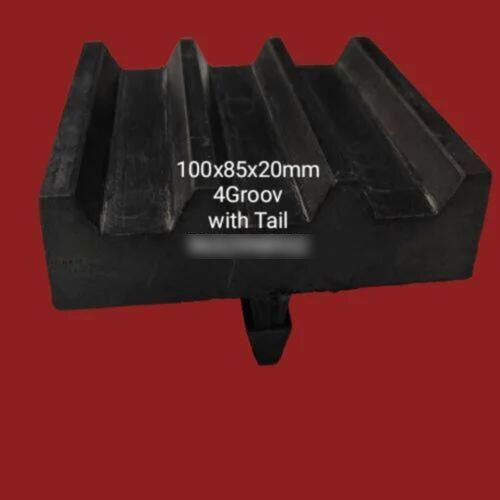

Groove Rubber Pad

Price 35.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Black

Product Type : Groove Rubber Pad

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS