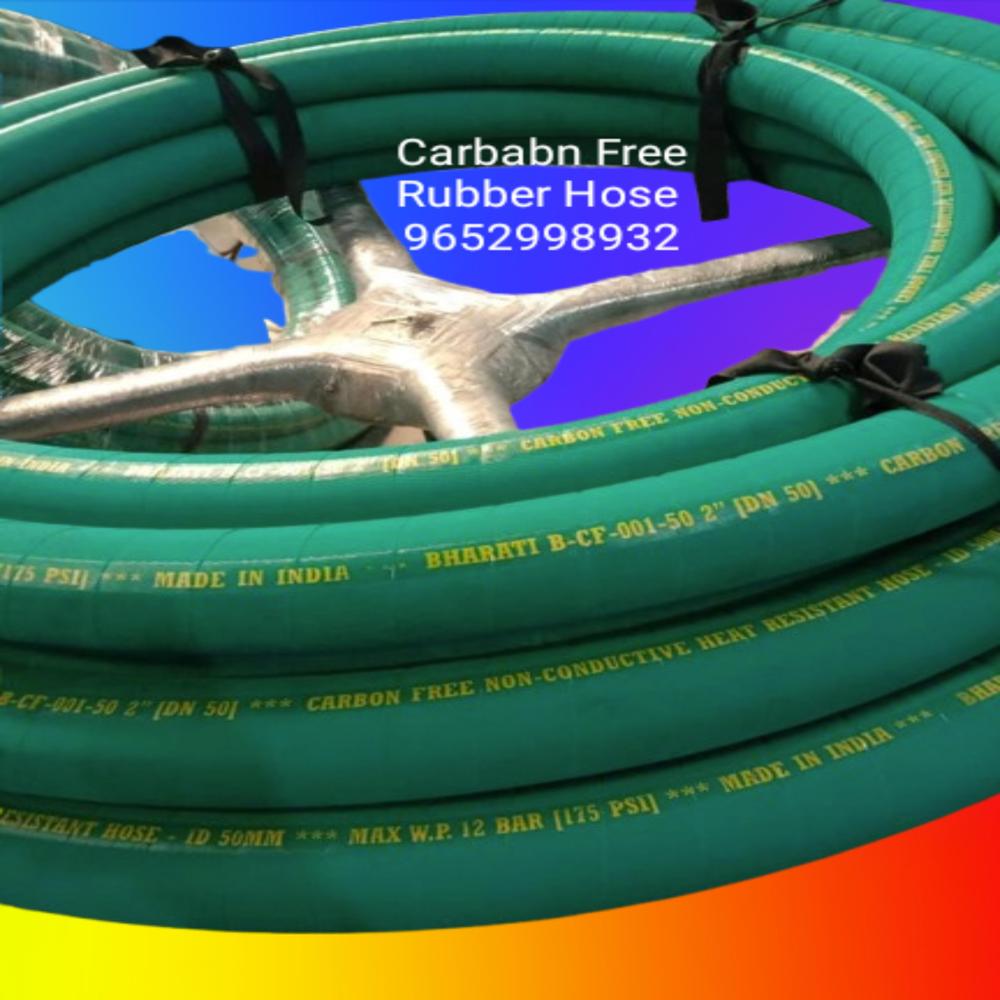

Carbon Free Rubber Hose Pipes

Price 167.0 INR/ Meter

Carbon Free Rubber Hose Pipes Specification

- Reinforcement

- Synthetic Textile Plies with Helical Wire

- Hardness

- 70 5 Shore A

- Cover

- Black Smooth EPDM Rubber, Abrasion & Weather Resistant

- Medium

- Cooling Water, Electrical Insulation Applications

- Shape

- Round

- Connection Type

- Plain / Flanged / Threaded

- Material

- Carbon Free Synthetic Rubber

- Temperature

- -40C to +120C

- Pressure

- up to 10 Bar

- Inside Diameter

- 9 mm to 100 mm

- Outside Diameter

- 17 mm to 114 mm

- Safety Factor

- Minimum 4:1

- Non-Toxic

- Yes

- Bursting Pressure

- Up to 40 Bar

- Ozone Resistance

- Excellent

- Application

- Suitable for induction furnaces, foundries, and steel mills

- Color

- Black with Orange/Red/Blue Line Marking

- Weight

- Varies with size and length

- Conductivity

- Electrically Non-Conductive (High Electrical Resistance)

- Packaging Type

- Coil or Reel Wrapped

- Length

- Up to 60 meters continuous

- Flexibility

- High

- End Connections

- As per customer requirements

About Carbon Free Rubber Hose Pipes

A Cable Coolant Rubber Hose is a specialized type of industrial rubber hose designed primarily for cooling applications, particularly in welding, cable manufacturing, and electrical industries. Its used to carry coolant fluids (typically water, glycol, or a mix) to dissipate heat generated in power cables or welding systems.

Key Features:

-

Material: Made from high-grade synthetic rubber (like EPDM or NBR) for flexibility and resistance to heat and chemicals.

-

Reinforcement: Often reinforced with synthetic textile or braiding for pressure resistance.

-

Temperature Resistance: Typically can withstand -30C to +100C (or more depending on the compound).

-

Pressure Rating: Varies by design, commonly up to 1015 bar.

Common Applications:

-

Cable cooling in power transmission and welding machines

-

Transformer and induction heating equipment

-

Hydraulic and pneumatic systems where cooling is required

Specifications Example:

| Property | Specification |

|---|---|

| Inner Diameter | 6 mm to 75 mm |

| Working Pressure | Up to 15 Bar |

| Temperature Range | -30C to +120C |

| Tube Material | EPDM / NBR / SBR |

| Reinforcement | High-tensile synthetic textile / braiding |

| Cover | Heat, ozone, and abrasion-resistant rubber |

Would you like help drafting a product description or catalog entry for your brand (Sandhya Enterprises)?

Superior Electrical Safety and Durability

Designed with synthetic textile plies and helical wire reinforcement, these hoses deliver excellent electrical insulation for hazardous industrial environments. The non-conductive carbon free rubber construction ensures that the hose remains safe to use around high voltage equipment, protecting both workers and machinery from electrical risks.

Versatile Applications and Robust Build

With a temperature tolerance from -40C to +120C, high ozone resistance, and a hard-wearing EPDM cover, these hoses excel under demanding conditions. Whether installed in foundries, steel mills, or induction furnaces, their flexibility and strength ensure reliable long-term service. Choose from plain, flanged, or threaded connections customized to your setup.

FAQ's of Carbon Free Rubber Hose Pipes:

Q: How is the carbon free rubber hose pipe beneficial for induction furnace operations?

A: The carbon free rubber hose pipe ensures complete electrical insulation, significantly reducing the risk of accidental electric current flow. This is particularly important in induction furnaces, where electrical safety is paramount to protect equipment and personnel.Q: What customization options are available for end connections on these hose pipes?

A: End connections can be tailored to your requirements, including plain, flanged, or threaded types. This flexibility allows seamless integration with any system configuration found in steel mills or foundries.Q: When should the hose be replaced or inspected for safety?

A: Regular inspection is recommended, particularly after prolonged use or exposure to extreme temperatures and pressures. If there are signs of wear, loss of flexibility, or any visible damage, the hose should be replaced to maintain safety standards.Q: Where are these carbon free rubber hoses typically used?

A: They are primarily used in induction furnaces, foundries, and steel mills across various industries in India, wherever cooling water or electrical insulation is needed under challenging conditions.Q: What makes this rubber hose suitable for harsh industrial environments?

A: The hose is constructed with abrasion and weather-resistant EPDM rubber, reinforced with synthetic textile plies and helical wire, making it durable and reliable. Its exceptional ozone resistance and operating temperature range ensure it performs reliably even in harsh settings.Q: How should the hoses be stored or transported for best performance?

A: The hoses are packaged in coils or reels and wrapped for protection during storage and transit. To maximize longevity, store them in a cool, dry place away from direct sunlight and chemical exposure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

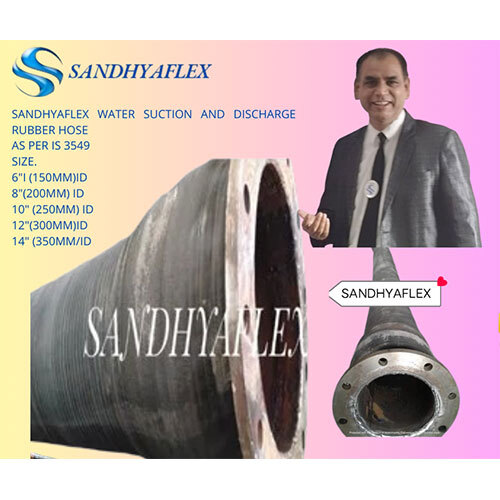

More Products in Industrial Rubber Hoses Category

Cement Feeding Rubber Hose With Flange

Price 1800 INR / Meter

Minimum Order Quantity : 100

Material : Rubber

Shape : Round

Color : Black

Sand Blasting Rubber Hose

Price 800 INR / Meter

Minimum Order Quantity : 100

Material : Rubber

Shape : Round

Color : Black

Transparent Water Suction and Discharge Rubber Hose

Price 4800.0 INR / Meter

Minimum Order Quantity : 1 Meter

Material : Other, PVC blended rubber compound

Shape : Round

Hardness : 65 5 Shore A

Soft and Long Water Suction and Discharge Rubber Hose

Price 4000.0 INR / Meter

Minimum Order Quantity : 100

Material : Other, Natural & Synthetic Rubber

Shape : Round

Hardness : 65 5 Shore A

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free