Compression Rubber Seal

Price 450.0 INR/ Meter

Compression Rubber Seal Specification

- Color

- Black

- Thickness

- 5-15 mm (customizable)

- Material

- EPDM Rubber

- Structure

- Flexible, Extruded

- Surface Finish

- Smooth or Textured

- Compression Set

- Good, less than 25%

- Temperature Range

- -40°C to 120°C

- Elongation at Break

- >300%

- Application

- Sealing joints, doors, and windows in industrial and commercial equipment

- Tensile Strength

- 8-15 MPa

- Shape

- U, D, P, E and customized profiles

- Feature

- Weather Resistant, Dust Proof, Anti-vibration, Durable

- Installation

- Easy to install, can be cut to length

- Hardness

- 60-70 Shore A

About Compression Rubber Seal

A compression rubber seal is a type of sealing device used to prevent the leakage of air, liquids, or gases by creating a tight and secure barrier when compressed between two surfaces. These seals are often used in various applications where a reliable, durable seal is needed to maintain pressure, prevent contamination, and ensure the integrity of a system. Compression rubber seals are commonly used in industries such as automotive, manufacturing, construction, and HVAC systems.

Key Features of a Compression Rubber Seal:

-

Compression and Flexibility:

-

The primary characteristic of a compression rubber seal is its ability to deform under pressure, creating a tight, leak-proof seal. When compressed between two surfaces, the rubber material fills the gaps and irregularities, ensuring a secure seal.

-

-

Material:

-

Rubber is the most common material used for compression seals because of its flexibility, elasticity, and ability to conform to different shapes and surfaces. Some common types of rubber used in compression seals include:

-

EPDM (Ethylene Propylene Diene Monomer): Highly resistant to weathering, ozone, and UV rays, making it ideal for outdoor and automotive applications.

-

Neoprene: Offers good resistance to oils, chemicals, and heat, commonly used in industrial and mechanical systems.

-

Nitrile Rubber (Buna-N): Known for its excellent resistance to oils, fuels, and chemicals, used in automotive and industrial sealing applications.

-

Silicone Rubber: Provides high-temperature stability and is often used in applications involving extreme temperatures.

-

-

-

Customizable Sizes:

-

Compression rubber seals come in a variety of shapes, sizes, and profiles, such as O-rings, gaskets, or custom extruded shapes, to suit specific sealing requirements.

-

-

Durability:

-

Rubber seals are designed to resist wear, pressure, and environmental factors like temperature fluctuations, moisture, and chemicals. Their durability makes them a reliable solution for long-term use.

-

-

Resilience:

-

Compression seals retain their original shape and sealing properties after being compressed, which ensures that they can provide consistent performance over time, even under continuous pressure.

-

Applications of Compression Rubber Seals:

-

Automotive:

-

Compression rubber seals are used in vehicles for door seals, window seals, and sealing around engine compartments. They prevent water, dust, and air from entering the vehicle and ensure smooth functioning of components like doors and windows.

-

-

Construction:

-

In construction, these seals are often used around windows, doors, and roofing to prevent water leakage, air drafts, and heat loss. They are also used in expansion joints and other structural applications where sealing between different materials is required.

-

-

HVAC Systems:

-

Compression rubber seals are used in heating, ventilation, and air conditioning systems to seal duct joints, ensuring efficient airflow and preventing air or fluid leaks.

-

-

Industrial Equipment:

-

These seals are often found in pumps, valves, and machinery that require a reliable seal to prevent leakage of fluids or gases under pressure. They are used in applications such as hydraulic systems, compressors, and reactors.

-

-

Electronics and Enclosures:

-

Compression seals are used in electronic enclosures to protect sensitive equipment from dust, moisture, and contaminants. They are particularly common in outdoor equipment and electronic devices that require protection from environmental elements.

-

-

Marine and Aerospace:

-

In marine and aerospace applications, compression rubber seals are used to prevent water and air leakage in critical systems, ensuring safety and preventing corrosion or damage from environmental factors.

-

Advantages of Compression Rubber Seals:

-

Leak Prevention:

-

The primary advantage of compression rubber seals is their ability to prevent leaks, whether its air, water, or other fluids. This helps maintain system integrity and prevents the contamination of sensitive components.

-

-

Wide Temperature Range:

-

Depending on the type of rubber used, compression seals can be designed to work in a wide range of temperatures, from very low temperatures in refrigeration systems to high temperatures in automotive engines or industrial machinery.

-

-

Chemical Resistance:

-

Many rubber materials are highly resistant to various chemicals, oils, and solvents, making compression seals ideal for industrial and automotive applications where exposure to harsh chemicals is common.

-

-

Cost-Effective:

-

Rubber seals are generally affordable compared to other sealing materials, making them a cost-effective solution for a wide variety of applications. They are also easy to replace when necessary.

-

-

Ease of Installation:

-

Compression seals are easy to install and dont require special tools or complex procedures. They can be fitted into grooves, channels, or around joints without much effort.

-

-

Long Lifespan:

-

With proper care and maintenance, compression rubber seals can provide a long lifespan, offering reliable performance over extended periods.

-

Types of Compression Rubber Seals:

-

O-Rings:

-

Circular rubber seals that are used in a variety of mechanical applications to seal joints and prevent leakage in fluid and gas systems.

-

-

Gaskets:

-

Flat rubber seals used to seal the joints between two flat surfaces. Gaskets are often used in automotive engines, industrial machinery, and pipe connections.

-

-

Custom Extruded Profiles:

-

Rubber seals that are custom extruded into various shapes to fit specific applications, such as sealing gaps around windows, doors, and machinery.

-

-

U-Channels and Seals:

-

U-shaped or C-shaped seals used to fit into grooves around doors, windows, or other openings to prevent leakage.

-

-

Face Seals:

-

Rubber seals designed to create a seal between two flat surfaces, often used in rotating equipment like pumps or valves.

-

Maintenance and Care:

-

Inspection: Compression rubber seals should be inspected regularly for signs of wear, such as cracking, deformation, or degradation due to environmental exposure. This is especially important for seals in high-temperature or high-pressure environments.

-

Cleaning: Keeping seals clean of dirt and debris ensures that they maintain their sealing properties. Regular cleaning can help prevent premature wear or damage.

-

Replacement: Over time, compression rubber seals may degrade or lose their sealing ability. It's essential to replace them when they show signs of wear to ensure proper sealing and prevent leaks.

Conclusion:

A compression rubber seal is an essential component in many applications requiring airtight or watertight seals. Its flexibility, durability, and cost-effectiveness make it an ideal choice for various industries, including automotive, construction, manufacturing, and HVAC systems. Whether used in doors, engines, machinery, or electronic enclosures, compression rubber seals play a crucial role in ensuring safety, efficiency, and the longevity of equipment.

Would you like more specific information on types of rubber materials for seals, or assistance with selecting a seal for a particular application? Let me know!

Versatile Applications

Compression Rubber Seals are suitable for sealing joints, doors, and windows across a range of industrial and commercial machinery. Their adaptability makes them a preferred choice for equipment manufacturers, fabricators, and installers seeking effective sealing solutions.

Engineered for Performance

Crafted from weather-resistant EPDM rubber, these seals exhibit high tensile strength (8-15 MPa) and excellent elongation (>300%). The flexible, extruded design ensures a reliable seal, while the smooth or textured finish supports both functionality and appearance.

Simple and Customizable Installation

These rubber seals are designed for easy installation; they can be cut to the required length for the perfect fit. Offered in assorted shapes (U, D, P, E) and thicknesses, they provide customization for unique equipment needs.

FAQ's of Compression Rubber Seal:

Q: How are compression rubber seals installed?

A: Our compression rubber seals are easy to install-simply cut them to the desired length and fit them into the target area, such as joints, doors, or window openings. No special tools are needed, simplifying on-site or retrofitting projects.Q: What makes EPDM rubber suitable for weather-exposed applications?

A: EPDM rubber is renowned for its exceptional weather resistance, making it resistant to UV rays, ozone, rain, and extreme temperatures (-40C to 120C). This durability ensures consistent performance and longevity in outdoor or exposed environments.Q: Where can these compression rubber seals be used?

A: These seals are ideal for industrial equipment, commercial doors and windows, HVAC systems, and any application requiring efficient sealing against air, water, dust, or vibration. They are widely used in manufacturing, fabrication, and building maintenance.Q: When should I consider replacing my existing rubber seals?

A: You should replace rubber seals when you notice signs of hardening, cracking, reduced flexibility, or persistent leakage. Using our high-performance EPDM seals enhances sealing efficiency and equipment reliability.Q: What are the benefits of using customized profile rubber seals?

A: Custom profile seals (U, D, P, E, or as needed) ensure a precise fit for your unique requirements, maximizing the effectiveness of the seal. Customization also allows adaptation to various thicknesses (5-15 mm) or complex equipment geometries.Q: How does the compression set performance benefit my application?

A: A low compression set (less than 25%) means the seal retains its shape and sealing force even after prolonged compression. This results in consistent protection against leaks and environmental ingress over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bridge Expansion Joint Category

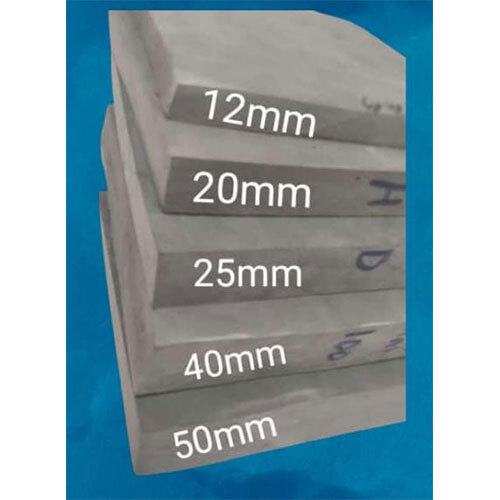

HD100 DURA BOARD

Price 350.0 INR / Piece

Minimum Order Quantity : 20 Pieces

Color : BLACK

Thickness : 12 Micrometers (um)

Size : 12,15,20,25

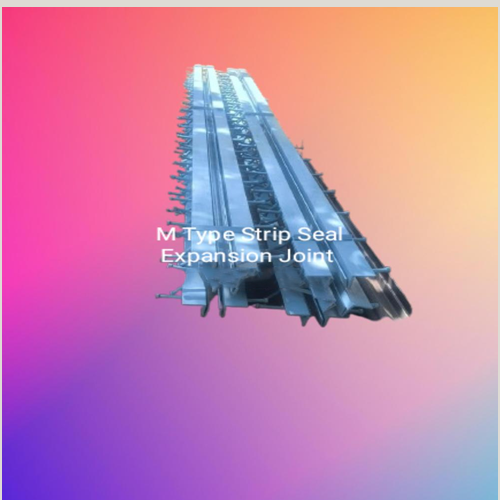

M Type Strip Seal Expansion Joint

Price 3000.0 INR / Meter

Minimum Order Quantity : 1 Meter

Color : Black / Metallic Grey

Thickness : 10 mm (Steel Edge Beam); 12 mm (Elastomeric Seal)

Material : Neoprene / Steel (as per design requirements)

Metal Beam Crash Barrier

Price 2500.00 INR / Meter

Minimum Order Quantity : 1 Meter

Color : Silver

Material : Steel

Size : Standard

Steel Amour Expansion Joint

Price 2000.00 INR / Meter

Minimum Order Quantity : 1 Meter

Color : Silver

Thickness : 10 Millimeter (mm)

Material : Mild Steel

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free