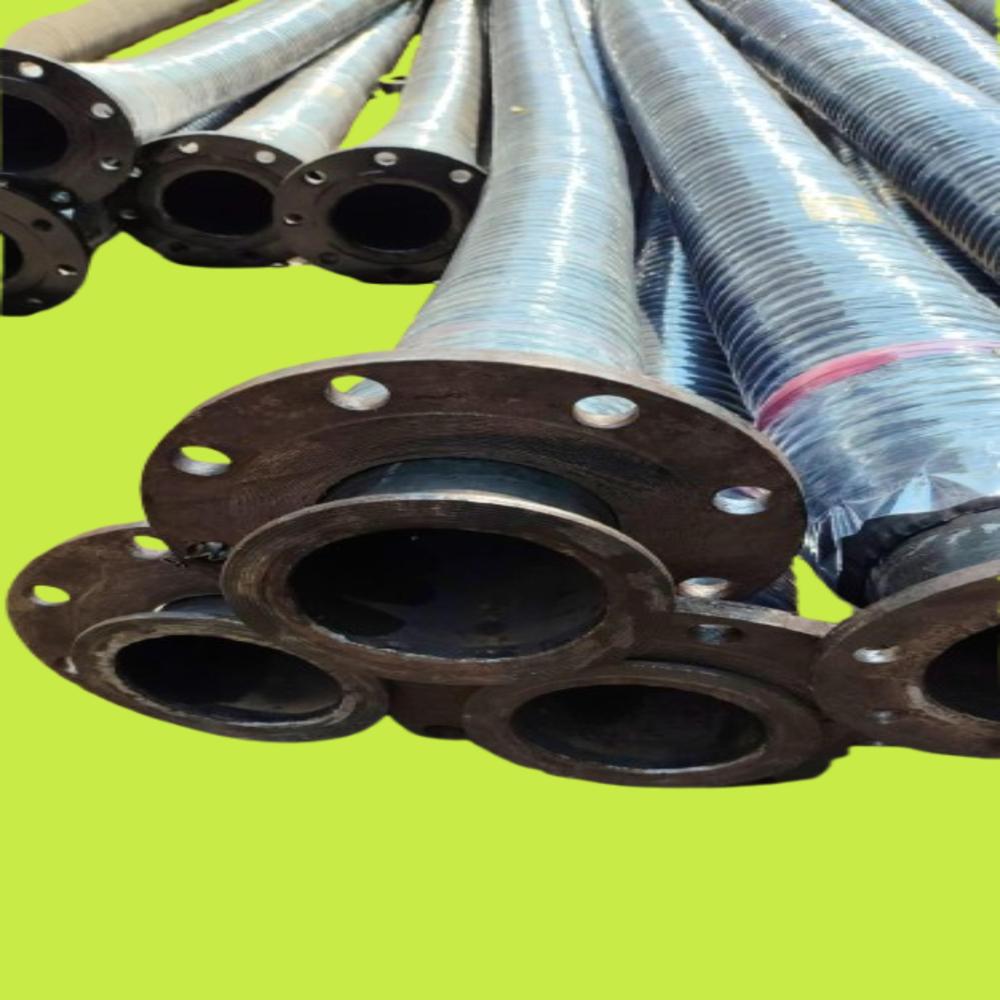

Fly Ash Rubber Hose with Fixed Flange

Price 2100.0 INR/ Meter

About Fly Ash Rubber Hose with Fixed Flange

Heres a detailed overview of a Fly Ash Rubber Hose with Fixed Flange, commonly used for transporting fly ash or similar abrasive materials in industrial environments.

Fly Ash Rubber Hose with Fixed Flange

Product Description:

A Fly Ash Rubber Hose with Fixed Flange is a flexible, abrasion-resistant hose specifically designed for the transportation of fly ash in pneumatic conveying systems or slurry pipelines. The fixed flange at both ends allows for secure, easy connection to machinery, silos, and piping systems.

Applications:

-

Fly Ash Handling Systems used in thermal power plants and cement factories.

-

Pneumatic Conveying for transporting dry bulk materials like fly ash, cement, lime, and other powders.

-

Bulk Material Transfer often used for construction materials or waste material management.

-

Silo Feeding transferring fly ash from pneumatic trailers to storage silos.

Construction:

| Component | Material/Details |

|---|---|

| Inner Lining | Abrasion-resistant rubber (e.g., Natural Rubber (NR), SBR) |

| Reinforcement | High-strength synthetic fabric or steel wire for pressure resistance |

| Outer Cover | Weather, UV, and ozone-resistant rubber |

| End Connections | Fixed steel or stainless steel flange (flanged ends for secure installation) |

| Flange Standards | ANSI, DIN, or custom flanges for easy bolted connection |

Typical Specifications:

| Specification | Value/Range |

|---|---|

| Inner Diameter (ID) | 2" to 12" (50 mm to 300 mm) |

| Length | 3 m to 10 m (custom lengths available) |

| Working Pressure | 5 to 20 bar (depending on size) |

| Burst Pressure | 30 to 60 bar (depending on design) |

| Temperature Range | -20C to +80C |

| Flange Type | Fixed flanges (ANSI, DIN) |

| Bend Radius | 6x to 10x the hose diameter |

Key Features:

-

Abrasion-resistant rubber liner to handle abrasive materials like fly ash.

-

High flexibility for easy installation and routing in constrained spaces.

-

Fixed flange connections ensure secure, leak-free installation to piping systems.

-

Weather and UV-resistant to maintain performance in outdoor or harsh environments.

-

Non-conductive properties for electrical safety.

Customizations & Options:

-

Custom flange sizes and materials (stainless steel for corrosive environments).

-

Longer lengths or larger diameters for specific projects.

-

Optional anti-static or electrically conductive versions for special applications.

-

Heat-resistant versions for handling hotter materials.

-

Reinforced hose construction for higher pressures or more abrasive material.

Would you like:

-

A datasheet or BOQ format for procurement?

-

Help sourcing suppliers in your region?

-

Assistance determining optimal hose size based on your system needs?

Let me know how I can assist!

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Feeding Rubber Hose Category

Cement Feeding Rubber Hose with Swival Flange

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS