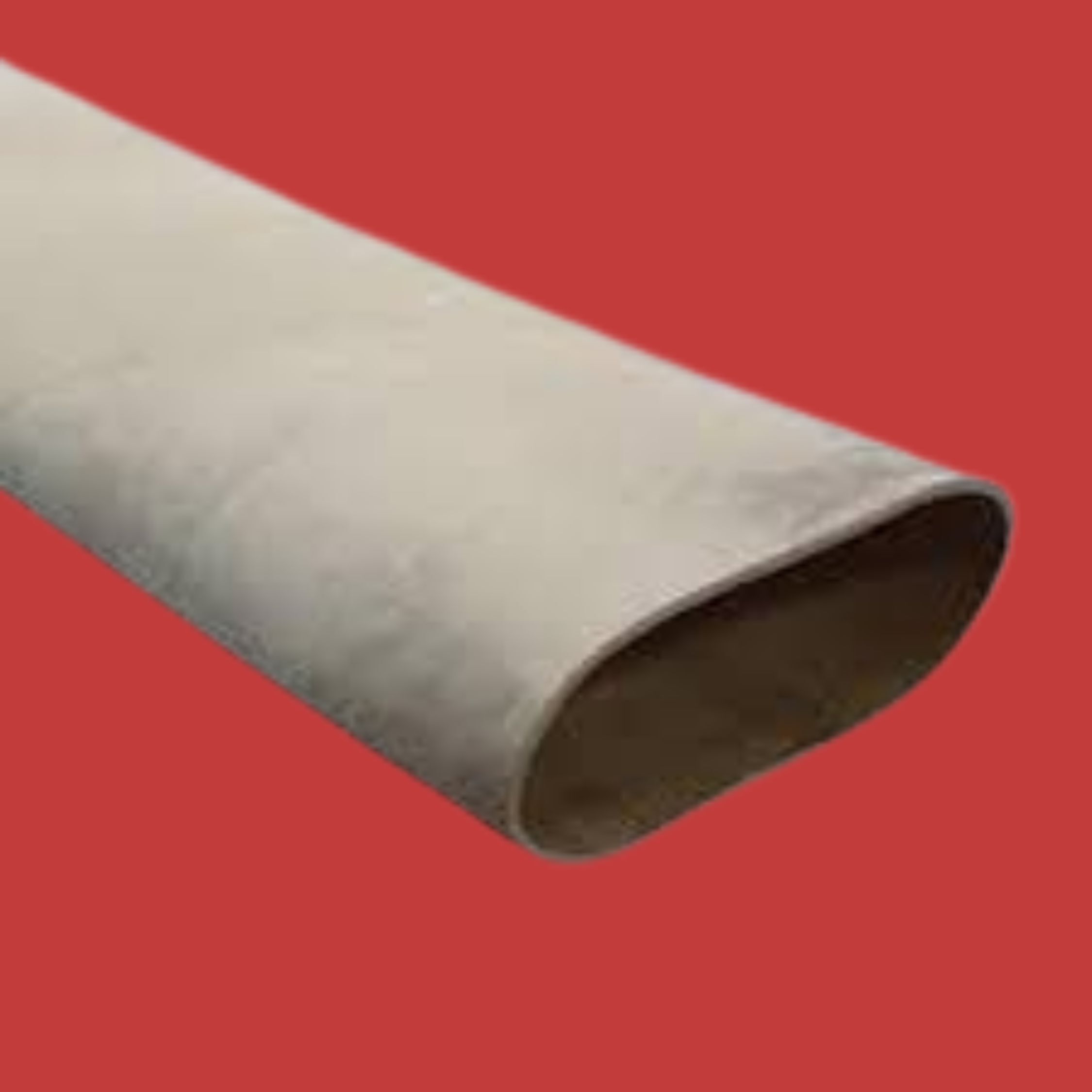

Rubber Discharge Chute

Price 500 INR/ Piece

Rubber Discharge Chute Specification

- Density

- 1.5 Gram per cubic centimeter(g/cm3)

- Style

- Flexible Discharge Chute

- Volatile Matter (%)

- <1.5%

- Size

- Standard and custom sizes available

- Part Type

- Discharge Chute

- Weight

- 3-30 kg (depending on size)

- Tolerance

- 2 mm

- Color

- Black

- Water Absorption

- Low

- Hardness

- 60 t 65 Shore A

- Rubber Type

- Natural/Synthetic Rubber

- Thickness

- 5 mm to 25 mm

- Temperature Resistance

- -30C to +80C

- Resistance level

- High abrasion, tear and weather resistance

- Length

- 1-15 Meter (m)

- Product Type

- Rubber Sleeve

- Flame Resistance Level

- Optional Fire-retardant grade available

- Natural Rubber

- Available

- Compression Ratio

- 1:6 (typical as per design)

- Feature

- Weather Resistance

- Ash %

- <1%

- Surface Finish

- Smooth or textured outer finish

- Thermal Conductivity

- 0.13 W/mK

- Components

- Rubber sleeve (single piece or sectional), mounting flange

- Diameter

- 100 mm - 1000 mm

- Tensile Strength

- 10-18 MPa

- Material

- Natural rubber/SBR/Neoprene/EPDM/Customized rubber compounds

- Nitrogen Content (%)

- <0.7%

- Usage & Applications

- Material transfer, bulk handling, discharge from conveyors and chutes in mining, quarry, and industrial plants

- Width

- Customizable, generally 200 mm - 1200 mm

- Environmental Resistance

- Resistant to ozone, UV, moisture and chemicals

- Shape

- Conical, cylindrical, or custom shape available

- Maintenance

- Low maintenance, easy to replace or repair

- Application Temperature

- Suitable for both indoor and outdoor installation

- Elongation at Break

- 300% minimum

- Installation

- Bolt-on or clamp connection

- Ageing Resistance

- Excellent, with anti-cracking properties

- Minimum Order Quantity

- 1 piece

- Packaging

- Wrapped with plastic film or wooden box

Rubber Discharge Chute Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 2 Pieces Per Day

- Delivery Time

- 10 Days

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- packing as per dimension

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About Rubber Discharge Chute

Our provided range of Rubber Sleeve is broadly used for protecting the power wires and cables. We use best quality rubber, sourced from the most authentic vendors to manufacture the sleeve. It is highly acclaimed in the market for its attributes such as light weight, smooth finishing and tear proof nature. Furthermore, we can make this Rubber Sleeve available for the clients in different sizes, diameters and finishing as per their requirements at most reasonable rates.

Designed for Longevity and Robust Performance

Thanks to its outstanding environmental and ageing resistance, the Rubber Discharge Chute offers reliable operation across harsh conditions. The specialized rubber blend delivers resistance to abrasion, tears, chemicals, and weather, ensuring sustained functionality whether installed indoors or outdoors. Low maintenance and straightforward repair or replacement processes minimize downtime, adding value for industrial users.

Customizable to Diverse Industrial Needs

Available in a range of sizes, shapes, and configurations, the discharge chute adapts to specific project requirements. You can specify standard or custom lengths (1-15 meters), diameters (100-1000 mm), widths (200-1200 mm), and thicknesses, with options for a smooth or textured surface. Choose from conical, cylindrical, or custom designs, suiting bulk handling demands in sectors like mining and quarrying.

FAQ's of Rubber Discharge Chute:

Q: How is the Rubber Discharge Chute installed in industrial setups?

A: The chute can be quickly installed using either bolt-on or clamp connections, making it adaptable to various mounting requirements on conveyors and discharge points. Its flexible design streamlines integration with existing systems and enables straightforward future adjustments.Q: What materials are used in manufacturing the Rubber Discharge Chute?

A: These chutes are crafted from high-performance natural rubber, SBR, Neoprene, EPDM, or customized rubber compounds as specified by application needs. This robust composition ensures superior resistance to abrasion, weather, chemicals, and mechanical stress.Q: Where can the Rubber Discharge Chute be used for material handling?

A: It finds usage in mining, quarrying, and industrial plants for bulk materials discharge from conveyors and chutes. Its versatility allows for both indoor and outdoor installations, performing reliably in environments exposed to UV, ozone, moisture, and chemicals.Q: What is the benefit of the chute's high elongation at break and tensile strength?

A: With a minimum elongation at break of 300% and tensile strength up to 18 MPa, the chute offers flexibility and durability under heavy loads and frequent movement. This ensures it withstands operational stress without cracking or tearing, reducing replacement frequency.Q: How easy is maintenance and replacement for the Rubber Discharge Chute?

A: These chutes require minimal maintenance due to their robust design and anti-cracking properties. Repairs or complete replacements are straightforward, thanks to the flexible material and accessible installation methods, helping maintain continuous operation.Q: What packaging options are available for shipping the Rubber Discharge Chute?

A: Each chute is securely packaged, either wrapped with plastic film or placed inside a wooden box. This protects the product from moisture, impacts, and environmental contamination during transit, ensuring it reaches you in optimal condition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

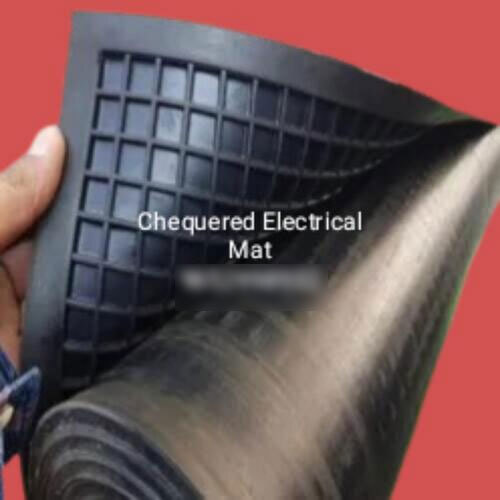

Checkered Rubber Sheet

Price 540.0 INR / Number

Minimum Order Quantity : 100

Usage & Applications : Flooring, walkways, stair treads, industrial work areas, antislip covering

Material : Rubber (Natural/Synthetic Blend)

Size : Custom sizes available

Color : Black

Conductive Rubber Sheet

Price 350 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Usage & Applications : Electronics, Gasket Sealing, EMI/RFI Shielding, Antistatic flooring, Workstations, Keypads, Electrical equipment insulation

Material : EPDM, Silicon, or Natural Rubber with conductive fillers

Size : Customizable as per requirement

Color : Black

Cutless Rubber Bearing

Price 1250.0 INR

Minimum Order Quantity : 1

Usage & Applications : Marine, Shipbuilding, Pump, and Propeller Shafts

Material : Rubber lined with metallic/bronze sleeve

Size : Standard and custom as per requirement

Color : Black

PVC water stopper

Price 60 INR / Meter

Minimum Order Quantity : 100

Usage & Applications : Industrial

Material : PVC

Size : 150mm x 6 mm

Color : Black

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free