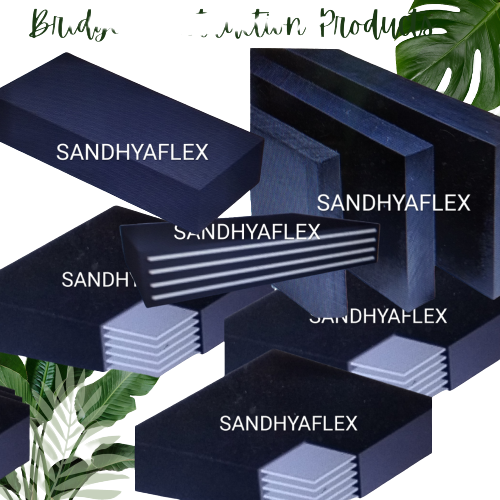

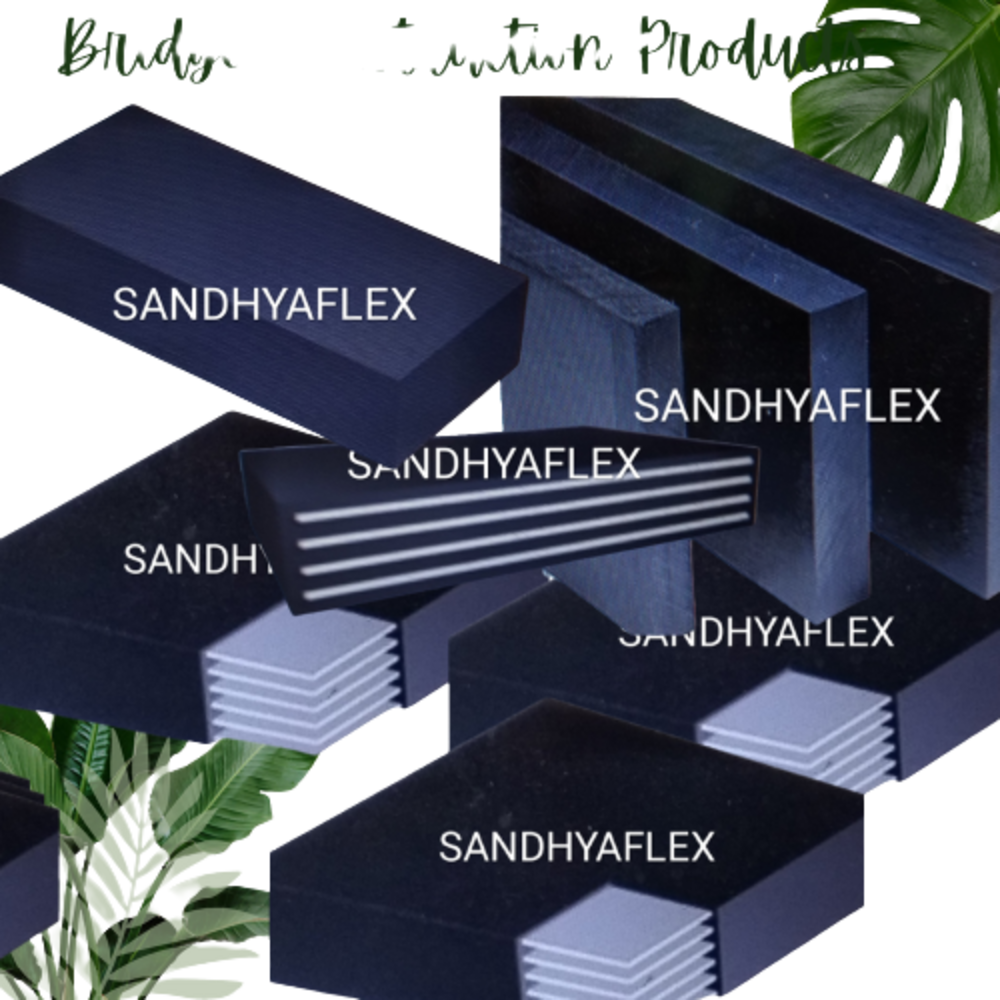

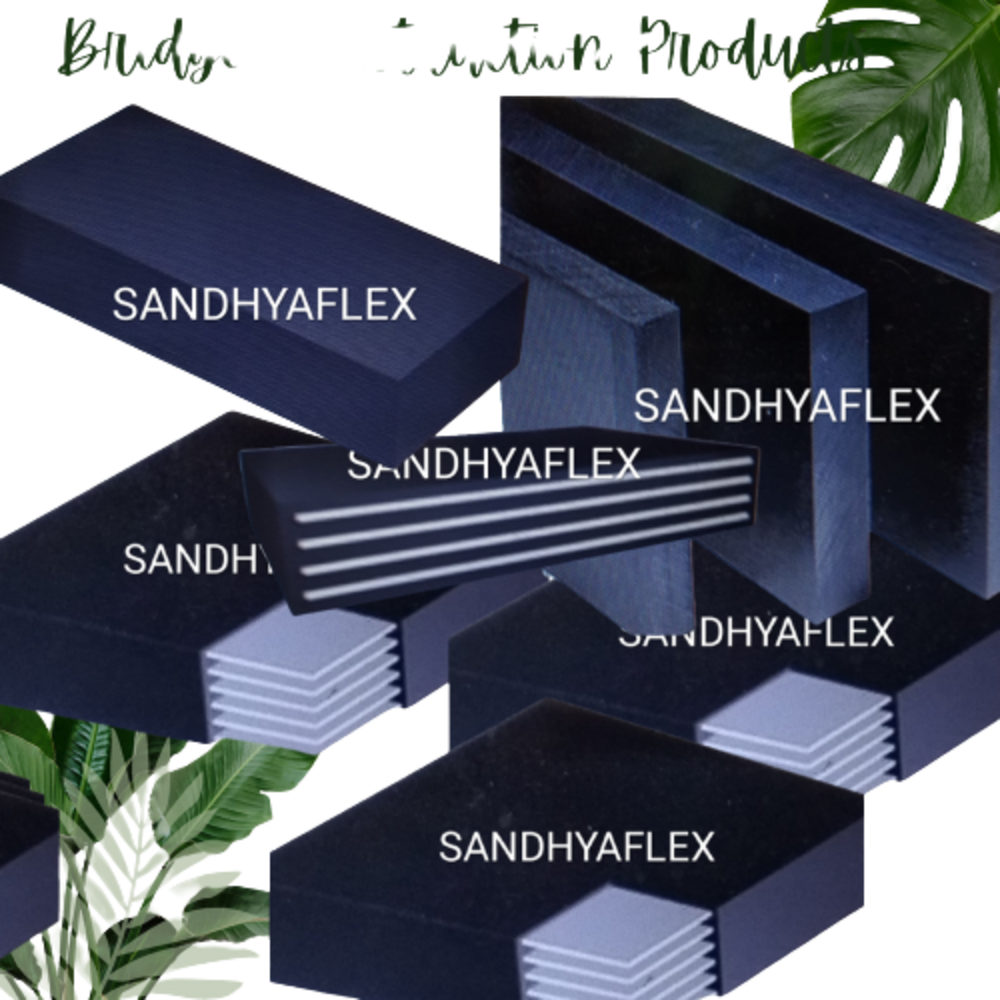

Rubber Elastomeric Bridge Bearing

Price 3500 INR/ Piece

Rubber Elastomeric Bridge Bearing Specification

- Thickness

- 22 to 144 Millimeter (mm)

- Usage

- Bridge Construction

- Material

- Rubber

- Size

- 22mm to 144m

- Product Type

- Elastomeric Bridge Bearing

- Color

- Black

- Warranty

- 15 Years date of Manufacturing

Rubber Elastomeric Bridge Bearing Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 25550 Pieces Per Day

- Delivery Time

- 15 Days

- Packaging Details

- Packing with HDPE Sheet

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About Rubber Elastomeric Bridge Bearing

Offering the finest Elastomeric Bridge Bearing, Sandhya Flex takes pleasure as a leading manufacturer of the products. We have segregated our infrastructure into several units with one of them as packaging unit. Here we meticulously pack our Elastomeric Bridge Bearing to ensure safe and secure deliverables. For the safe storage of the manufactured products, we have installed our facility equipped with all the modern amenities for absolute quality satisfaction.

The features of the elastomeric bridge bearing involve a strong design, simple installation and high quality. Also, it allows movement in all the directions you desire. Moreover, it finds it application in bridges, auditoriums, buildings and stadiums among others. They have exceptional tensile strength along with good elongation strength.

They are easy to install for various applications. Above all, they require less maintenance as well. They are precisely manufactured by specialists and experts as per the national and international norms and standards. Also, we use premium quality raw material to manufacture these elastomeric bridge bearing which are sourced from reliable vendors. Further, we assure the best quality, superior performing, durable and energy-efficient elastomeric bridge bearing which you can get from Sandhya Flex at competitive prices in the market.

Reliable Performance for Infrastructure Projects

Our Rubber Elastomeric Bridge Bearings are engineered to provide lasting support and flexibility, critical for successful bridge construction. Manufactured using high-quality rubber, these bearings offer outstanding resistance to environmental factors and daily wear, ensuring bridges remain safe and functional over time.

Comprehensive Distribution Network in India

Whether you are searching for a manufacturer, fabricator, supplier, or retailer, these bridge bearings are available nationwide through an extensive network of dealers and wholesalers. This wide reach ensures timely delivery and expert support for infrastructure projects of all scales.

FAQ's of Rubber Elastomeric Bridge Bearing:

Q: How are rubber elastomeric bridge bearings installed in bridge construction?

A: These bearings are installed between the bridge deck and supporting substructure. They are precisely placed to absorb movements from thermal expansion, load shifts, or ground movement, thus minimizing stress on the bridge itself.Q: What is the thickness range available for these bridge bearings?

A: The bearings come in thicknesses and sizes ranging from 22mm to 144mm, making them suitable for a variety of bridge designs and load requirements.Q: When does the 15-year warranty period begin for the bearings?

A: The warranty is valid for 15 years starting from the date of manufacturing, ensuring long-term support and reliability for your construction projects.Q: Where can I purchase these rubber elastomeric bridge bearings in India?

A: You can obtain these bearings through various channels, including dealers, fabricators, manufacturers, wholesalers, traders, suppliers, and retailers spread across India.Q: What process is used in manufacturing these bridge bearings?

A: The bearings are fabricated using advanced molding techniques with high-grade rubber to ensure uniformity, performance, and long-lasting durability under demanding bridge conditions.Q: How do these bearings enhance the safety and longevity of bridges?

A: By absorbing and distributing the loads and movements caused by traffic, wind, or temperature changes, these bearings help prevent structural damage, thereby boosting the bridge's lifespan and safety.Q: What are the primary benefits of using rubber elastomeric bearings in bridges?

A: They provide excellent flexibility, resistance to aging and environmental impacts, simple installation, and require minimal maintenance, making them a cost-effective choice for contemporary bridge construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elastomeric Bridge Bearing Category

Heavy Duty Elastomeric Bridge Bearing

Price 3265 INR / Cubic Centimeter

Minimum Order Quantity : 100 Cubic Centimeters

Lubrication Type : Other

Thickness : 22 to 144 Millimeter (mm)

Structure : Sliding Bridge Bearing. A friction force is generated in sliding bearing and it is imposed on substructure, superstructure and sliding bearing itself. Rocker Bridge Bearing. Rocker Bridge Bearing. Pin bearing is a fixed bearing that make room for rotation movement through the application of steel pin. It has similar structure and component like rocker bearing apart from the bottom of pin bearing which is flat and fixed to the concrete pier, as can be observed in Figure4. Pin Bearing for Bridges. Both rocker and pin bearings are mainly employed in steel bridge structure. Rocker and pi

Bearing Type : Other

L Type Spider Seris Pad

Price 90.0 INR / Number

Minimum Order Quantity : 1 Number

Lubrication Type : Other, No lubrication required (drytype flexible pad)

Thickness : As per model (see drawing/spec sheet)

Structure : L Type Spider Series

Bearing Type : Other, Spider Coupling Pad

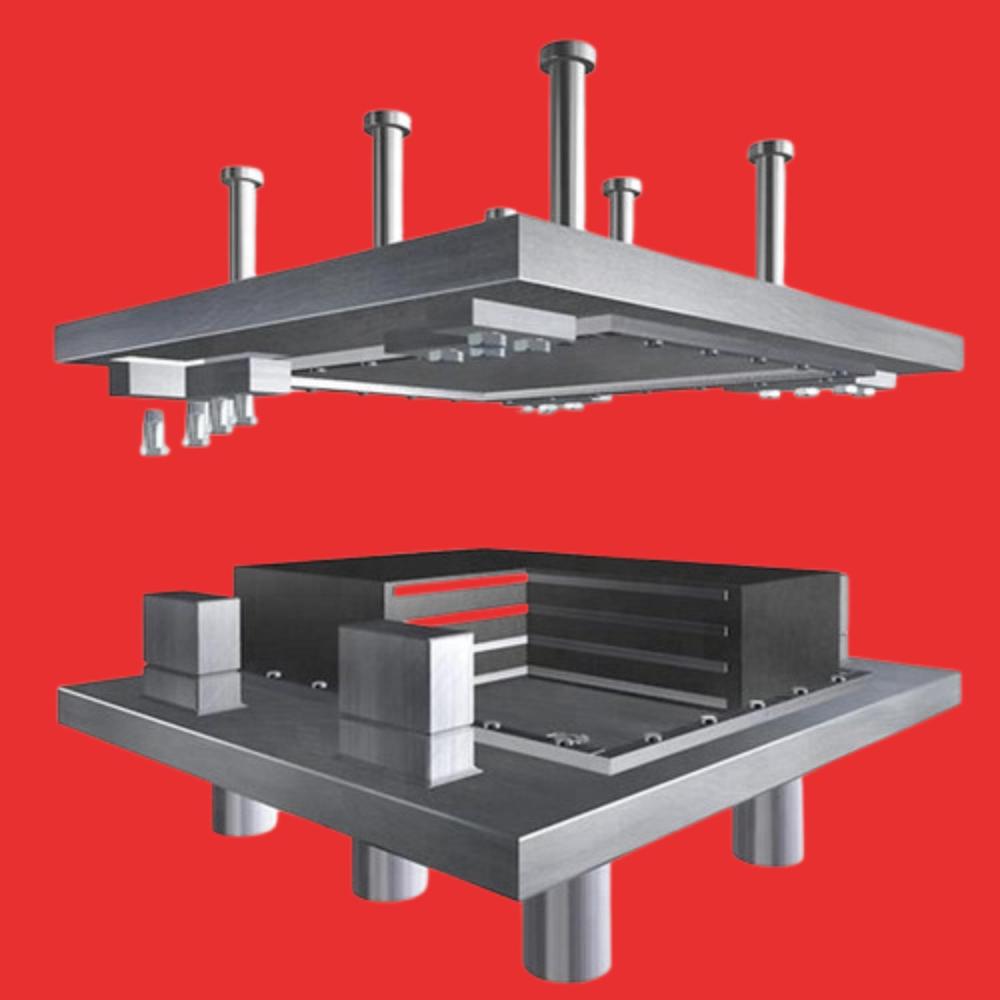

Ealstomeric Bride Bearing with Top and Bottom Steel Plate

Price 15000.0 INR / Number

Minimum Order Quantity : 1 Number

Lubrication Type : Other, Selflubricated (no additional lubrication required)

Thickness : 20 mm to 100 mm standard or per design

Structure : Laminated Elastomeric Pad with Embedded Steel Plates

Bearing Type : Other, Elastomeric Bridge Bearing with Top & Bottom Steel Plate

elastomeric bearings

Price 5000.0 INR / Number

Minimum Order Quantity : 1 Number

Lubrication Type : Other, Maintenancefree, selflubricating elastomer

Thickness : 12 mm to 100 mm or as specified

Structure : Laminated Rubber with Steel Plates

Bearing Type : Other, Elastomeric Bearing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free