Strip Seal Expansion Joint

Price 3000 INR/ Meter

Strip Seal Expansion Joint Specification

- Surface Treatment

- Painted

- Max. Temperature

- -10 to 100 Deg Celsius (oC)

- Material

- Iron

- Usage

- Bridge Construction

- Size

- as per Drg

- Connecting Type

- Welding

- Product Type

- Strip Seal Expansion Joint

- Color

- Gray

Strip Seal Expansion Joint Trade Information

- Minimum Order Quantity

- 100 , , Meter

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Per Day

- Delivery Time

- 4 Days

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Strip Seal Expansion Joint

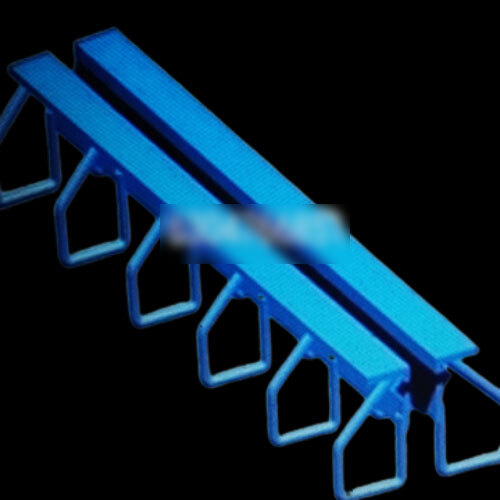

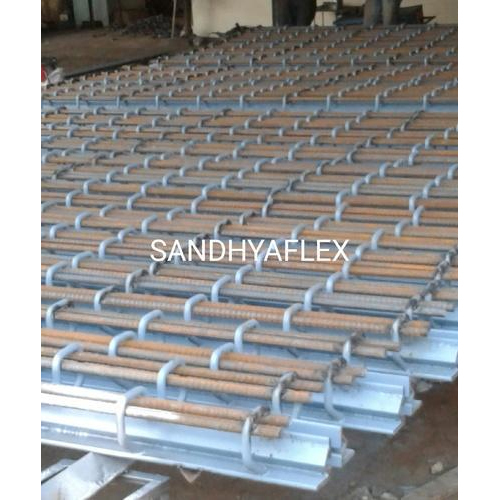

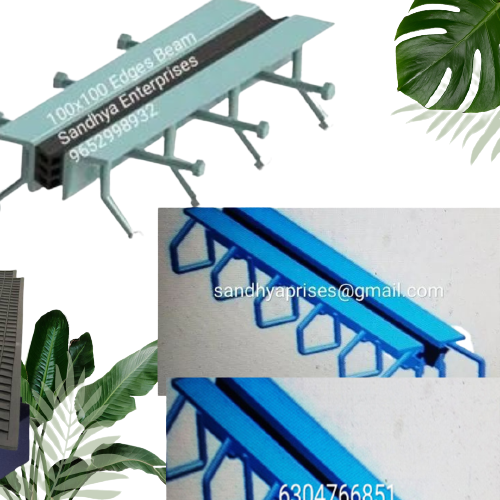

Technical Details Bridge Expansion Joint Gap 40.0mm (Movement up to 80mm). Bridge Expansion Joint consist of two edge beams with anchorages and with Neoprene sealing element held firmly in the housing of edge beams that guarantee the water tightness the joint. The maximum gap between the edge beams at the road surface when the joint fully opens due to maximum contractions of the deck shall be limited to 80mm for comfortable passage of traffic. The edge beams protects the adjacent bridge deck concrete from damage due to vehicular impact and also transfer the vehicular loads to the deck structures through robust anchorage system. Typical Bridge Expansion Joint is shown in the figure below.

Bridge Expansion Joint

Rs : / R.Mtr

GST:18% Extra

Packing and Forwording Extra

Superior Bridge Expansion Joint Solution

Our Strip Seal Expansion Joint offers an efficient and reliable method to manage bridge movements caused by temperature fluctuations. Designed with high-grade iron and a protective painted surface, the joint provides excellent corrosion resistance. Its welded construction ensures maximum stability, contributing to longer lifespan and minimal maintenance needs for bridge decks.

Engineered for Versatile Bridge Applications

These expansion joints are tailored to precise drawing specifications, making them suitable for various bridge projects across India. The adaptability in size and robust fabrication process ensure each joint is custom-fitted to its intended use, significantly optimizing performance and structural integrity for new installations or renovation projects.

FAQ's of Strip Seal Expansion Joint:

Q: How is the Strip Seal Expansion Joint installed on bridges?

A: The Strip Seal Expansion Joint is typically installed by welding it securely to the bridge structure as per the provided drawings. This process ensures a robust and seamless connection that accommodates the expansion and contraction of bridge decks.Q: What benefits does the painted surface treatment provide for the expansion joint?

A: The painted surface treatment protects the iron from corrosion and environmental wear, enhancing durability and reducing maintenance requirements even when exposed to fluctuating temperatures and harsh weather.Q: When should the Strip Seal Expansion Joint be used in bridge construction?

A: This expansion joint should be used during the construction or renovation phase of bridges, particularly when accommodating thermal movement and structural shifts is crucial for safety and longevity.Q: Where are Strip Seal Expansion Joints most commonly installed?

A: They are predominantly installed in Indian bridge projects, including highways, flyovers, and other elevated structures where temperature variation may cause expansion or contraction of concrete decks.Q: What is the typical process for producing a Strip Seal Expansion Joint?

A: Manufacturers in India fabricate these joints from iron, shape them according to project drawings, apply a protective paint, and prepare them for welding installation, ensuring they meet specific quality and size criteria.Q: How does using the Strip Seal Expansion Joint benefit bridge maintenance?

A: By accommodating structural movement and reducing stress on concrete decks, these joints minimize the likelihood of cracking and costly repairs, ultimately extending the service life of the bridge.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bellow And Expansion Joint Category

Industrial Rubber Expansion Joint

Price 12000 INR / Unit

Minimum Order Quantity : 100 Units

Material : Other

Surface Treatment : Other, Smooth Rubber Finish

Connecting Type : Others, Flanged

Head Code : Round

Compression Seal Expansion Joint

Price 15000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Iron

Surface Treatment : Painted

Connecting Type : Welding

Head Code : Square

Strip Seal Expansion Joint 16mm

Price 3000 INR / Meter

Minimum Order Quantity : 100

Material : Iron

Surface Treatment : Painted

Connecting Type : Welding

Head Code : Square

Bridge Strip Seal Expansion Joint

Price 3000 INR / Meter

Minimum Order Quantity : 100 Meters

Material : Iron

Surface Treatment : Painted

Connecting Type : Welding

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free