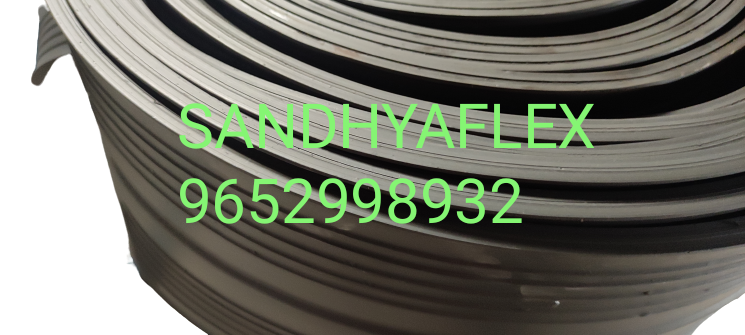

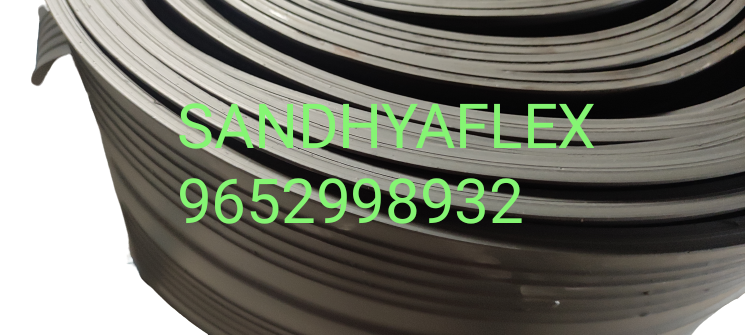

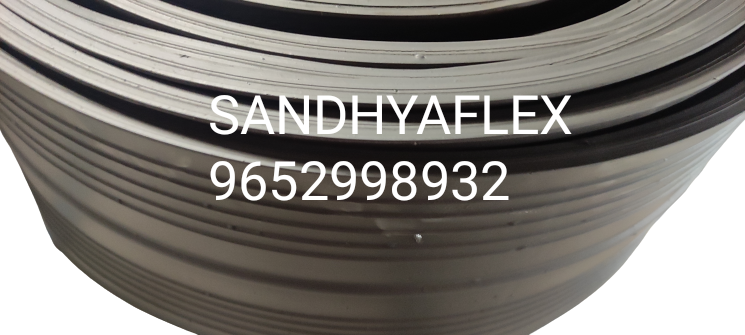

Dumbell Type PVC Water Stopper

Price 100 INR/ Meter

Dumbell Type PVC Water Stopper Specification

- Usage

- PVC water stoppers are used in construction to prevent the passage of water through joints in concrete structures. These flexible and watertight devices are designed to create a seal in joints, helping to ensure the integrity and durability of the construction. Here are some common usages of PVC water stoppers: 1. **Expansion Joints:** - PVC water stoppers are used in expansion joints of concrete structures. These joints allow for the expansion and contraction of concrete due to temperature changes and other factors. The water stoppers prevent water from infiltrating through these joints. 2. **Construction Joints:** - In construction, especially in the casting of large concrete structures, PVC water stoppers are used in construction joints to create a watertight seal. This helps prevent water from entering the structure during and after construction. 3. **Water Tanks and Reservoirs:** - PVC water stoppers find application in the construction of water tanks and reservoirs. They are used to create watertight seals in joints, ensuring that water is securely contained without leakage. 4. **Basements and Foundations:** - In below-grade structures like basements and foundations, PVC water stoppers are employed to prevent water infiltration through joints. This is crucial for maintaining a dry and stable environment. 5. **Tunnels and Subway Construction:** - PVC water stoppers are used in the construction of tunnels and subways to create seals in joints and prevent water ingress. This is essential for the safety and stability of underground structures. 6. **Dams and Canals:** - Large concrete structures like dams and canals utilize PVC water stoppers in joints to prevent water seepage. This helps maintain the structural integrity of the dam or canal. 7. **Swimming Pools:** - In the construction of swimming pools, PVC water stoppers are used to create watertight seals in joints. This ensures that the pool structure remains water-resistant and prevents leaks. 8. **Retaining Walls:** - PVC water stoppers are employed in the construction of retaining walls to prevent water from penetrating through joints. This is important for preventing erosion and maintaining the stability of the wall. 9. **Bridges and Culverts:** - In bridge construction, PVC water stoppers are used in expansion joints and other critical areas to prevent water infiltration. This protects the bridge structure from the potential adverse effects of water exposure. 10. **Roads and Highways:** - PVC water stoppers may be used in the construction of infrastructure such as roads and highways, especially in structures like culverts and underpasses, to ensure that water does not penetrate through joints. 11. **Pipe Penetrations:** - In areas where pipes penetrate through concrete structures, such as basements or utility tunnels, PVC water stoppers can be used to seal the gaps around the pipes and prevent water ingress. 12. **Joint Repair and Retrofitting:** - In situations where existing joints may be prone to water infiltration, PVC water stoppers can be used in repair and retrofitting projects to enhance the water resistance of the structure. PVC water stoppers are crucial elements in construction, particularly in structures where water resistance is essential. Their flexibility, durability, and ability to create effective seals make them valuable components in ensuring the longevity and safety of concrete structures exposed to water or moisture.

- Material

- Poly Vinyl Chaloride

- Type

- Dumbell Tyoe

- Size

- 150x6mm

- Product Type

- Dumbell Type

- Application

- Selection of appropriate PVC water stopper Ribbed Type It has a multi-purpose water stopper design to be used for the expected differential settlement of poured concrete and a firm concrete grip desired. Dumbbell Type With greater variation in temperature, expansion and contraction of joints happen. Dumbbell type water stoppers are the suggested ones for these cases. Kicker (Surface Type) Where the embedded types cannot be used owing to interference of steel reinforcement, these are placed externally. Installation procedure: During installation, using small wires, the water stoppers are tied to the steel framework through the eyelets. Also, certain metal clamps are used to grip the water stop seal and keep it in proper position. Initially, half of the water stopper is places in the concrete. It leaves the other half extended. Then, the other half is embedded that leaves the centre bulb free for expansion and contraction movements. Applications Of PVC Water Stoppers Public Utilities: For bridges, road embankments, tunnels, water tanks, water filtration systems, swimming pools, sewage plants, clarifiers, dams, canals, reservoirs, aqueducts and irrigation projects cooling towers. Buildings: For basements, foundations slabs, masonry joints, retaining walls, terraces, overhead & underground water tanks and Industries: For fertilizer steel, chemical plants, waste treatment plants, atomic reactors, thermal & hydro power stations and shipyard & docks. Precautions to take while water stopper installation They are vulnerable to damage during the construction process The concrete compaction around the water stopper should be taken care of. If not, it can dislocate and lead to a risk of honeycomb formation. This might result in leakage through concrete instead of the joint. Methods for joining PVC water stoppers with heater blade Water stoppers can be joined on the site using a simple electrical heater blade. Water bars having the same width and design should be sharply levelled with a knife at the Turn on the Electric Heater Blade. Wait till it becomes hot Place the water stopper on both sides of heater blade. Press it until it melts but without burning Remove the heater blade upward Join the molten ends quickly. Hold them together firmly for approximately 20 to 30 seconds.

- Color

- Black, White and Blue

- Hardness

- 65 Shore

Dumbell Type PVC Water Stopper Trade Information

- Minimum Order Quantity

- 100 Meter

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Packing with HDPE Cover 25Mtr/Roll Elastomeric bridge bearings are used in bridge construction to fulfill several important functions and provide various benefits. Here are some key uses of elastomeric bridge bearings: 1. Load Transfer: Elastomeric bridge bearings serve as load-bearing components that transfer vertical loads from the bridge superstructure to the substructure. They distribute the weight of the bridge and the live loads (such as traffic) to the bridge piers or abutments. 2. Movement Accommodation: Bridges are subject to movements caused by factors like temperature fluctuations, wind loads, and traffic-induced vibrations. Elastomeric bridge bearings are designed to accommodate these movements, allowing for expansion, contraction, rotation, and translation of the bridge components. This flexibility helps prevent structural damage and maintains the integrity of the bridge. 3. Vibration Damping: Elastomeric bridge bearings possess inherent damping properties. They absorb and dissipate vibrations generated by traffic, wind, or other external forces. This damping capability reduces the transmission of vibrations to the bridge superstructure, enhancing the comfort and safety of bridge users. 4. Seismic Isolation: Elastomeric bridge bearings can act as seismic isolators. During an earthquake, they absorb and dissipate seismic energy, reducing the forces transmitted to the bridge structure. This helps protect the bridge from severe damage and enhances its seismic resilience. 5. Expansion Joint Support: Elastomeric bridge bearings are commonly used in conjunction with expansion joints. They provide support to the expansion joint system, allowing for smooth movement and accommodating thermal expansion and contraction of the bridge deck. 6. Durability and Longevity: Elastomeric bridge bearings are engineered to withstand harsh environmental conditions, such as temperature variations, moisture, and UV exposure. They offer excellent durability and can maintain their performance over an extended period, reducing the need for frequent maintenance and replacement. 7. Cost-effectiveness: Elastomeric bridge bearings are generally more cost-effective compared to other bearing types. They offer a reliable and efficient solution for load transfer and movement accommodation, contributing to the overall cost-effectiveness of bridge construction and maintenance. The specific use and application of elastomeric bridge bearings depend on factors such as bridge design, structural requirements, expected loads, and environmental conditions. It's crucial to consult with structural engineers and follow design specifications to ensure proper selection and installation of elastomeric bridge bearings in a given bridge project.

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Dumbell Type PVC Water Stopper

Sandhya Enterprises are one of the top manufacturers in India. Water Stoppers are the flexible plastic strips that are used to provide a physical barrier to water. The barriers can be at concrete joints in basements, water-retaining structures like water tanks, swimming pools, structural foundations and other constructions of below ground level. Water stoppers are also known as water bars and seal construction joints. In a typical water stopper, there are two identical halves on both sides of the central bulb. They serve as an additional extension aiming to increase the path length for water entering behind the edge of water stopper.

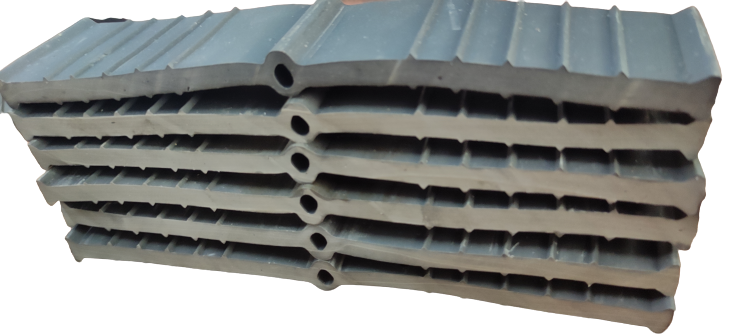

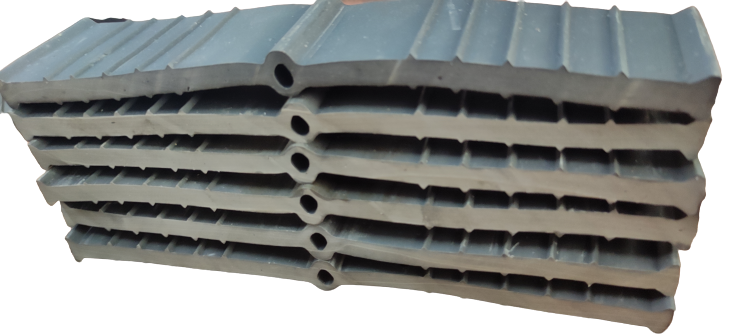

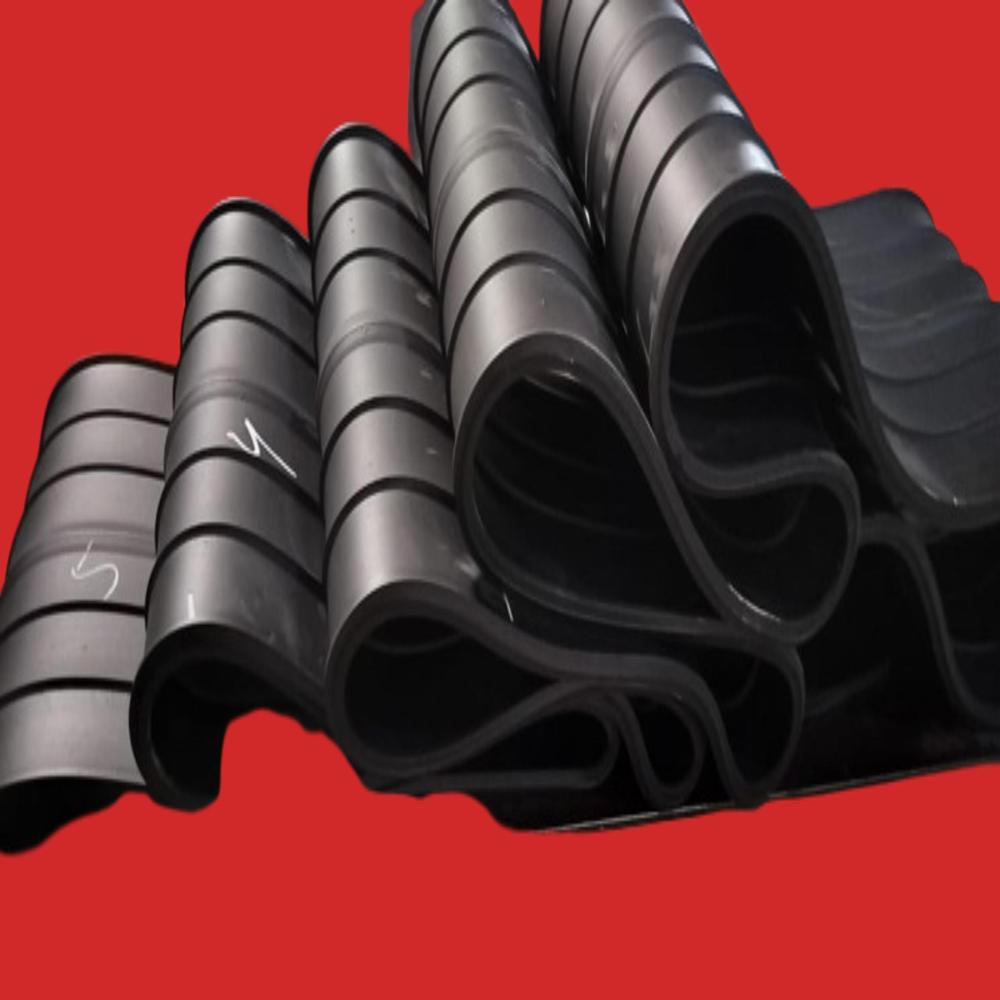

Compounding of PVC Water Stopper

Anti-ageing customized plastic compound is used for manufacturing the water stoppers. Alongside, it has PVC as a base polymer. Moreover, the properties it exhibit are high elasticity and tensile strength, immunity to corrosion, excellent weather resistance, unaffected by acids, alkalis, metals, salts and other chemicals. Other properties include lower water absorption, high hydrostatic pressure withstanding capacity, heavy turbine shock bearing alongside earthquakes and floods.

Application in construction industry

- The PVC water stopper acts as a sealant at RCC Masonry concrete joints alongside preventing any water seepage through the joints.

-

A PVC water stopper is a type of construction material used to prevent the passage of water through joints or gaps in structures such as concrete walls, floors, or basements. It is commonly used in applications where water leakage needs to be controlled or prevented, such as in swimming pools, water tanks, tunnels, or underground structures.

PVC water stoppers are made from polyvinyl chloride (PVC), a durable and flexible plastic material. They are designed in various shapes and sizes to accommodate different joint configurations and construction requirements. The most common types of PVC water stoppers include:

1. Straight Water Stopper: This type of water stopper is used in straight joints or construction joints where two concrete sections meet. It provides a barrier against water infiltration.

2. Internal and External Corners: These water stoppers are specifically designed to fit into the internal and external corners of joints, ensuring a watertight seal at these critical areas.

3. Bulb-Type Water Stopper: This water stopper features a bulbous shape that provides additional flexibility and sealing capacity. It is suitable for applications where joints are subject to movement or expansion.

4. Ribbed Water Stopper: Ribbed water stoppers have a ribbed surface that enhances the grip and bonding with concrete. This type of water stopper offers excellent sealing capabilities and is commonly used in high-pressure water applications.

PVC water stoppers are typically installed during the concrete pouring process. They are embedded within the joints, ensuring a secure and watertight seal. The flexibility of PVC allows the water stopper to accommodate movement or settling of the surrounding structures without compromising its sealing properties.

It is important to follow the manufacturers guidelines and consult with a qualified engineer or contractor for the appropriate selection and installation of PVC water stoppers based on the specific project requirements.

-

A PVC water stopper, also known as a PVC water stop, is a device used in construction to prevent the passage of water through joints or openings in concrete structures, such as expansion joints, construction joints, and pipe penetrations. It is commonly used in various applications, including basements, water tanks, swimming pools, tunnels, and underground structures.

PVC water stoppers are made from high-quality polyvinyl chloride (PVC) material, which offers excellent durability, flexibility, and resistance to water and chemical substances. They are available in different shapes and sizes to suit specific construction requirements.

The primary function of a PVC water stopper is to create a watertight seal between concrete elements, preventing water ingress and leakage. It is installed during the construction process, typically embedded in the concrete at joints or openings where water might enter. The water stopper forms a barrier that prevents the passage of water, even under hydrostatic pressure.

Some common types of PVC water stoppers include:

1. Straight PVC Water Stopper: This type is used for straight joints or where minimal movement is expected.

2. Internal PVC Water Stopper: Designed for internal joints or structures, it provides a reliable seal against water.

3. External PVC Water Stopper: This type is used for external joints, providing protection against water infiltration from the outside.

4. Swelling PVC Water Stopper: This special type of water stopper has a swelling compound that expands when exposed to water, providing an enhanced seal.

PVC water stoppers are considered cost-effective, easy to install, and provide long-lasting protection against water leakage in concrete structures. However, its important to choose the appropriate type and size of water stopper based on the specific construction requirements and the anticipated water pressure. Consulting with a structural engineer or construction professional is recommended to ensure the correct selection and installation of PVC water stoppers.

-

Versatile Applications Across Industries

Dumbell Type PVC Water Stoppers are widely employed in public utilities such as bridges, tunnels, sewage plants, water tanks, dams, and canals. They are also vital in residential and industrial settings, used in basements, retaining walls, foundation slabs, and chemical plants. Their robust construction and reliable watertight sealing make them invaluable for both new builds and retrofitting projects, ensuring lasting protection against moisture infiltration.

How the Dumbell Type Water Stopper Works

These water stoppers are installed at concrete joints to absorb movements due to thermal expansions, contractions, and settlements. During installation, they are tied to steel frameworks using wires or clamps to hold them firmly in place. A unique feature is the bulbous center, which remains free to flex, ensuring reliable sealing even with joint movement. This design preserves structural integrity while enabling necessary concrete flexibility.

Simple Installation and Maintenance Process

Installation involves securing the stopper in position with wires or metal clamps through pre-made eyelets. Half of the stopper is embedded in the initial concrete pour, with the rest incorporated in the subsequent phase, leaving the central bulb free for movement. For joining multiple lengths, an electrically heated blade fuses the ends, producing a secure and continuous seal. Proper compaction and careful handling are crucial to avoid damage and ensure effectiveness.

FAQs of Dumbell Type PVC Water Stopper:

Q: How does a Dumbell Type PVC Water Stopper function in concrete joints?

A: The Dumbell Type PVC Water Stopper is embedded across concrete joints, particularly where expansion and contraction are expected. Its central bulb design accommodates joint movements, effectively preventing water infiltration and maintaining the structures water-tightness.Q: What are the common applications of the Dumbell Type PVC Water Stopper?

A: This water stopper is used in structures where watertight jointing is critical, including bridges, retaining walls, tunnels, water tanks, basements, dams, reservoirs, swimming pools, and underground utilities. It ensures long-term protection against leakage in both public and industrial projects.Q: When should a Dumbell Type be chosen over other water stopper profiles?

A: Dumbell Type water stoppers should be selected for joints exposed to wide temperature variations or differential structural movements, where expansion and contraction are significant. Their flexibility makes them ideal for such dynamic conditions compared to other types like ribbed or kicker water stoppers.Q: Where is the Dumbell Type PVC Water Stopper typically installed?

A: This stopper is generally positioned at construction or expansion joints within concrete structures, such as the midsection of slabs, around pipe penetrations, or at the base of retaining walls. It is embedded between concrete pours to provide a continuous moisture barrier.Q: What is the process for installing and joining PVC water stoppers onsite?

A: PVC water stoppers are tied to reinforcement bars using wires or clamps before concrete pouring. To join two lengths, both ends are leveled, melted using a heated blade, and pressed together until fused. This forms a seamless, watertight connection across the joint.Q: What precautions should be observed during installation?

A: Care must be taken to avoid damaging the water stopper during construction. Proper compaction around the stopper is essential to maintain its position, prevent displacement, and eliminate risks such as honeycomb formation, which could compromise water resistance.Q: What key benefits do Dumbell Type PVC Water Stoppers offer in construction?

A: They provide flexible, chemical-resistant, and durable waterproof seals, effectively preventing water ingress and structural damage. Their ease of installation and adaptability for various joint movements make them suitable for a wide range of construction projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Water Stopper Category

PVC Hand Rail

Price 60.0 INR / Meter

Minimum Order Quantity : 1 Meter

Type : Hand Rail Cover Profile

Application : Staircase Hand Railings, Residential & Commercial Buildings

Hardness : Shore A 6585

Thickness : 3 mm

300mm PVC water stopper

Price 230.0 INR / Meter

Minimum Order Quantity : 1 Meter

Type : Center Bulb Type

Application : Used in Concrete Structures for Water Seepage Control

Hardness : 6575 Shore A

Thickness : 8 mm

PVC Chamfer 20*20mm

Price 50.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Chamfer

Application : Edge Protection, Corner Beading, Formwork in Concrete Construction

Hardness : Shore A 705

Thickness : 2 mm

300mm x8mm PVC Water stopper

Price 190.0 INR / Meter

Minimum Order Quantity : 1 Meter

Type : Expansion Joint Type

Application : Concrete Construction Joints, Water Retaining Structures

Hardness : Shore A 65 5

Thickness : 8mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free