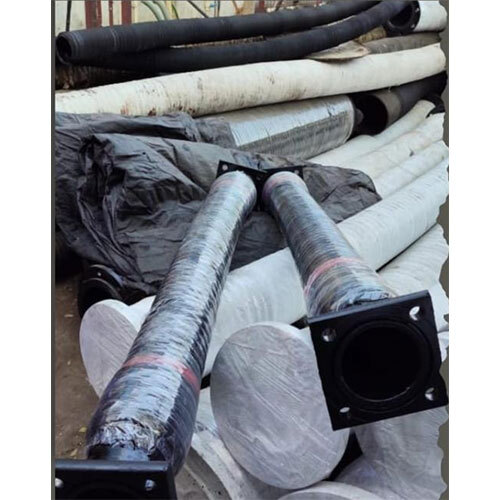

Slurry Rubber Hose

Price 4025.0 INR/ Meter

Slurry Rubber Hose Specification

- Hardness

- Medium

- Medium

- High Water Content Liquid

- Shape

- Round

- Usage

- Industrial

- Material

- Rubber

- Size

- Standard

- Color

- Black

- Warranty

- Yes

About Slurry Rubber Hose

A Slurry Rubber Hose is a type of heavy-duty hose designed for the transportation of slurrya mixture of water and solid particles like sand, mud, or chemicals. These hoses are commonly used in industries such as mining, construction, dredging, and wastewater treatment, where there is a need to move abrasive, viscous, or particle-laden liquids.

Slurry rubber hoses are designed to withstand high abrasion, pressure, and chemical exposure, making them ideal for harsh environments and demanding applications.

Key Specifications:

| Parameter | Details |

|---|---|

| Material | Rubber (usually NR, SBR, EPDM, or NBR) with special reinforcements |

| Diameter | Typically ranges from 50mm to 250mm, depending on the volume of slurry being transported |

| Working Pressure | Typically 10 bar to 20 bar, but higher pressure ratings are available for specialized applications |

| Reinforcement | Includes textile reinforcement or steel wire for added pressure resistance and durability |

| Temperature Range | Usually -10C to +70C, but can be customized for higher temperature resistance |

| Length | Common lengths are 5m, 10m, 20m, or custom lengths |

| Surface Type | Available in smooth or corrugated finish, depending on the application and required flexibility |

| Color | Typically black or green, but other colors are available based on specific customer needs |

| Abrasion Resistance | Designed to resist abrasion and cutting, ensuring longevity in harsh environments |

| Chemical Resistance | Some versions are made with materials that are resistant to corrosive chemicals commonly found in slurry mixtures |

Function and Purpose:

-

Slurry Transport: The primary function of a slurry rubber hose is to safely and efficiently transport slurrya mixture of solid particles suspended in waterfrom one location to another, such as from a dredging operation to a disposal site.

-

Abrasion Resistance: These hoses are specifically designed to handle the abrasive nature of slurry, which can wear down traditional hoses quickly.

-

Flexible and Durable: The hoses are flexible, allowing for easy installation in complex or limited space environments while maintaining durability under harsh conditions.

-

High Pressure Resistance: Slurry hoses are often subjected to high-pressure environments, so they are reinforced with materials like steel wire or textile braiding to maintain structural integrity under pressure.

Common Applications:

-

Mining Operations: Used to transport mineral slurry, such as coal, sand, and gravel, in mining sites or dredging operations.

-

Dredging: Essential in the dredging of waterways, rivers, and harbors, where muddy or sandy slurry needs to be transported for disposal.

-

Construction Sites: Used for the transport of slurry during concrete mixing, grouting, or pumping.

-

Wastewater Treatment: Utilized in sludge pumping and the disposal of slurry from treatment processes.

-

Civil Engineering: For the transportation of cement slurry or other thick materials in construction or tunneling projects.

-

Agricultural Projects: Used in irrigation systems or in the transport of fertilizers and pesticide mixtures.

Advantages:

-

High Abrasion Resistance: Designed to handle the abrasive nature of slurry mixtures, ensuring longevity and reduced wear.

-

High Pressure & Temperature Resistance: These hoses can withstand high-pressure pumping and extreme temperatures, making them suitable for challenging environments.

-

Flexibility: The hoses flexible nature allows for easy handling, installation, and movement, even in tight spaces.

-

Leak-Proof: Prevents leaks and minimizes the risk of slurry spillage, which is especially important in environments where contamination needs to be avoided.

-

Durable Construction: Resistant to wear and tear, chemicals, UV rays, and weathering, making them suitable for both indoor and outdoor use.

-

Cost-effective: Provides a reliable and long-lasting solution, reducing the need for frequent replacements.

Performance Features:

-

Abrasion-Resistant Lining: The inner lining is designed to resist the damage caused by solid particles, ensuring a longer service life.

-

Pressure Rating: Can handle high-pressure conditions, making them ideal for industrial pumping operations.

-

Flexibility and Handling: Despite their durability, these hoses remain flexible, which is important for installation in complex areas or for moving around on-site.

-

Chemical Resistance: Some slurry hoses are made from chemical-resistant rubber, making them suitable for transporting corrosive slurry or waste.

-

Smooth Flow: Ensures smooth flow of slurry without the risk of clogging or blockages, even when dealing with thicker materials.

Installation and Use:

-

Connection Fittings: Slurry hoses typically have flanged, quick-connect, or clamp-style fittings to securely attach to pumps, piping systems, or other equipment.

-

Handling: Due to their heavy-duty construction, they are often easier to move with specialized lifting equipment, although smaller sizes can be handled manually.

-

Storage: When not in use, these hoses should be stored in a cool, dry area away from direct sunlight and UV exposure. They should be coiled or rolled up to prevent damage to the hose structure.

-

Maintenance: Regular inspection for signs of wear, cracks, or punctures is crucial. The hose should be cleaned after use to remove any slurry residue that may cause clogs or other issues.

Performance Features:

-

Long-lasting Durability: Resists abrasion, pressure, and wear from harsh slurry mixtures, reducing downtime and maintenance.

-

Reliable for Heavy-duty Applications: Withstands high-pressure environments where slurry is being transferred under intense conditions.

-

Corrosion & UV Resistance: Capable of enduring outdoor conditions, including exposure to UV rays, without degrading.

-

High Flow Capacity: Facilitates the transportation of large volumes of slurry, making it suitable for both small and large-scale operations.

Would you like:

-

A specific size or type of slurry rubber hose for a particular application?

-

Recommendations on sourcing suppliers or manufacturers for slurry hoses?

-

Installation guides or maintenance tips for slurry hose systems?

Let me know what you need, and Ill help guide you through the best options!

Built for Demanding Industrial Use

This slurry rubber hose is engineered to withstand the rigors of high water content liquid transfer in various industrial environments. Its robust construction delivers consistent performance while maintaining flexibility for convenient handling and installation.

Wide Availability Across India

As a reliable solution, this hose is supplied through a comprehensive network in India, including dealers, manufacturers, and retailers. Our broad presence ensures timely availability and expert support for all your industrial fluid transport needs.

FAQ's of Slurry Rubber Hose:

Q: How can I purchase the slurry rubber hose in India?

A: You can acquire the slurry rubber hose from authorized dealers, manufacturers, suppliers, traders, and wholesalers throughout India. Our extensive distribution network ensures that standard sizes are readily available for industrial use.Q: What are the main benefits of using this slurry rubber hose?

A: The hose provides durability, flexibility, and resistance to wear, making it ideal for transferring high water content liquids. Its medium hardness and robust construction support reliable and efficient operation even in demanding conditions.Q: When is it recommended to replace the slurry rubber hose?

A: It is advisable to replace the hose if you notice significant wear, cracking, or reduced flexibility to maintain safety and efficiency. Regular inspection and adherence to maintenance guidelines prolong its service life.Q: Where can this hose be effectively used?

A: This rubber hose is designed for industrial environments that require the conveyance of liquids with high water content, such as mining, construction, or manufacturing facilities across India.Q: What is the process for warranty support?

A: For warranty support, contact the supplier or manufacturer from whom you purchased the hose. Provide your purchase details to receive assistance, including assessment and possible replacement as covered by the warranty terms.Q: How should the slurry rubber hose be used for best results?

A: Ensure the hose is installed according to manufacturer guidelines and operated within its specified pressure and liquid compatibility limits. Regular checks and proper storage further enhance its performance and lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Rubber Hoses Category

Rubber Hose pipe with Square Flange Fitting

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : round

Hardness : 70

Inside Diameter : 102 Meter (m)

Color : BLACK

Air Rubber Hose

Price 125.0 INR / meter

Minimum Order Quantity : 1 Meter

Shape : Round

Hardness : 60 Shore A

Inside Diameter : 25 Millimeter (mm)

Color : Black

Black Color Rubber Strip

Price 55.0 INR / Meter

Minimum Order Quantity : 100

Shape : Round

Hardness : 55 TO 65

Color : Black

Fire Fightng Rubber Suction Hose

Price 13500 INR / Meter

Minimum Order Quantity : 2

Shape : Round

Hardness : 65 5 Shore A

Inside Diameter : 63 mm, 75 mm, 100 mm (customizable)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free