VIBRATING SCREEN RUBBER BEADING

Price 160.00 INR/ Meter

VIBRATING SCREEN RUBBER BEADING Specification

- Ash %

- Yes

- Hardness

- Medium

- Color

- Black

- Surface Finish

- Polished

- Material

- Rubber

- Size

- Standerd

About VIBRATING SCREEN RUBBER BEADING

Got it you're asking specifically about Vibrating Screen Rubber Beading. Here's a concise, no-fluff guide tailored to practical use:

What is It?

Rubber Beading for vibrating screens is a protective rubber strip that sits between the screen mesh and the metal frame. Its main job? To absorb shock and vibration, reduce wear, and keep the mesh tight and properly aligned.

Typical Specs:

| Feature | Details |

|---|---|

| Material | Natural Rubber / EPDM / Neoprene |

| Hardness | 6070 Shore A |

| Profile | U-type (most common), also C, L types |

| Sizes | U-Profile: 5mm to 10mm groove widths; height 2550mm |

| Color | Usually black |

Applications:

-

Mining and aggregate screens

-

Quarry and crusher vibrating screens

-

Industrial screening units

Installation:

-

Clean the screen frame

-

Fit the U-beading snugly onto the screen frame edge

-

Insert the wire mesh into the groove

-

Clamp or bolt to secure

Benefits:

-

Prolongs screen mesh life

-

Reduces noise and vibration

-

Prevents metal-to-metal contact

-

Easy to replace and cost-effective

If youre looking to buy, I can help list specs for a purchase order or recommend suppliers based on your region. Want a template for ordering or tech drawing example?

Efficient Protection for Vibrating Screens

Rubber beading acts as a protective barrier on vibrating screens, safeguarding metal edges from wear due to frequent movement. Its medium hardness and polished finish offer both resilience and aesthetic appeal, ensuring smooth operation in industrial environments. This component is vital for maintaining structural integrity and efficient screening processes.

Extensive Supply Network in India

Manufactured and supplied by a network of dealers, producers, and wholesalers across India, vibrating screen rubber beading is widely accessible for bulk and retail requirements. Leading fabricators ensure each batch adheres to prescribed standards for material quality and finish, supporting the needs of diverse sectors nationwide.

FAQ's of VIBRATING SCREEN RUBBER BEADING:

Q: How is vibrating screen rubber beading installed on screening equipment?

A: Vibrating screen rubber beading is fitted along the edges of screen panels, typically placed between metal frames using adhesives or fasteners. The process helps prevent metal-to-metal contact and facilitates smoother vibration transfers.Q: What is the key benefit of using rubber beading on vibrating screens?

A: Rubber beading minimizes wear and tear by cushioning the vibration and sealing the screen edges. This not only prolongs the life of the equipment but also reduces operational noise and maintenance frequency.Q: When should rubber beading be replaced on vibrating screens?

A: Replacement is recommended when visible signs of wear, cracks, or deformation occur, or during routine maintenance checks to maintain optimal equipment efficiency and safety.Q: Where can I source vibrating screen rubber beading in India?

A: You can purchase vibrating screen rubber beading from manufacturers, suppliers, dealers, and wholesalers operating across India, with options for both bulk and retail procurement.Q: What is the process involved in manufacturing vibrating screen rubber beading?

A: The manufacturing process includes shaping medium-hard rubber to standard dimensions, controlling ash percentage for quality, and polishing the surface for a clean finish. The resulting beading is then distributed to dealers, fabricators, and suppliers.Q: How is the material quality of the rubber beading ensured?

A: Quality is maintained through strict adherence to standard ash percentages, regular hardness testing, and polished surface finishing, guaranteeing consistency and durability in each batch.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

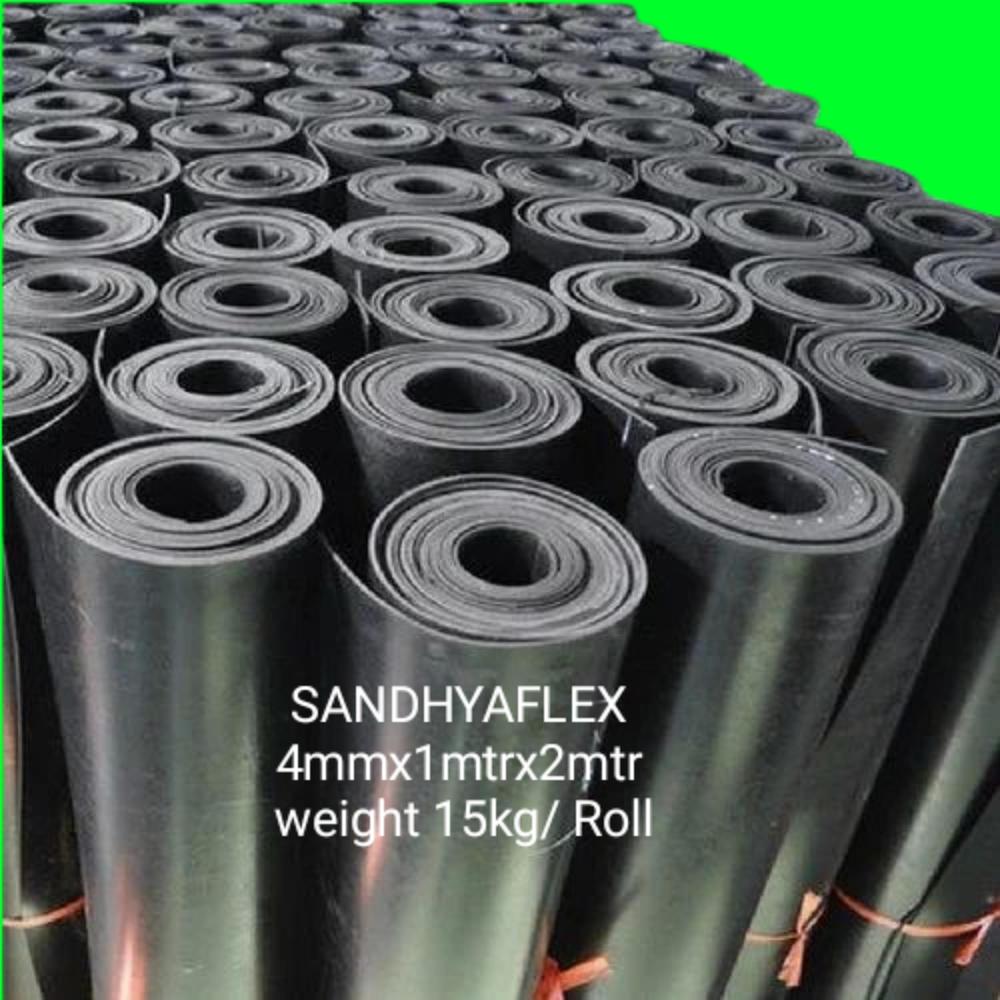

4mmx1mtr x2mtr Plain Rubber Sheet

Price 55.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Color : Black

Hardness : 605 Shore A

Size : 4mm x 1m x 2m

Usage & Applications : Industrial flooring, Gasket manufacturing, Insulation pad, Antivibration, Automotive and general sealing purposes

Rubber Buffer

Price 2700.0 INR

Minimum Order Quantity : 1

Color : Black

Hardness : 5580 Shore A

Size : Customizable as per requirement

Usage & Applications : Widely used as shock absorbers and vibration isolators in machinery, vehicles, and industrial equipment.

PVC water stopper

Price 60 INR / Meter

Minimum Order Quantity : 100

Color : Black

Hardness : 60A

Size : 150mm x 6 mm

Usage & Applications : Industrial

Di Rubber Ring

Price 90.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Color : Black

Size : Standerd

Usage & Applications : Insulation

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free