IS:7654 Chemical Rubber Hose

Price 1000.0 INR/ Meter

IS:7654 Chemical Rubber Hose Specification

- Resistance level

- Chemical Resistance

- Feature

- Chemical rubber hoses are designed to handle the transfer of various chemicals, acids, and corrosive materials in industrial applications. The features of these hoses are crucial to ensure safety, reliability, and performance in conveying potentially hazardous substances. Here are some key features of chemical rubber hoses: 1. **Chemical Resistance:** - The primary feature of chemical rubber hoses is their resistance to a wide range of chemicals. These hoses are constructed from rubber compounds that can withstand the corrosive effects of acids, bases, solvents, and other aggressive substances. 2. **Material Composition:** - Chemical hoses are made from specialized rubber materials such as EPDM (ethylene propylene diene monomer), UHMW (ultra-high molecular weight) polyethylene, FKM (fluoroelastomer), or other chemical-resistant elastomers. The choice of material depends on the types of chemicals the hose will come into contact with. 3. **Reinforcement:** - Chemical hoses often feature reinforcement layers, which can include textile fabrics, wire helixes, or other materials. Reinforcements enhance the strength and durability of the hose, allowing it to withstand pressure and prevent kinking or collapse. 4. **Temperature Resistance:** - Chemical rubber hoses are designed to operate within specific temperature ranges. They should maintain their flexibility and structural integrity even in extreme temperatures, ensuring reliable performance in various industrial environments. 5. **Pressure Ratings:** - Hoses are rated for different pressure levels to suit various industrial processes. The pressure rating is an important consideration to ensure that the hose can handle the pressure requirements of the specific application. 6. **Flexibility:** - Chemical hoses need to be flexible to facilitate easy handling, installation, and maneuvering in different industrial settings. Flexible hoses are particularly important when working in confined spaces or when connecting to equipment with moving parts. 7. **End Connections:** - Chemical hoses typically have end connections, such as flanges or couplings, that allow them to be securely attached to equipment or other hoses in the system. Proper end connections help prevent leaks and ensure a secure transfer of chemicals. 8. **Color Coding:** - Some chemical hoses are color-coded to indicate their compatibility with specific types of chemicals. This helps users quickly identify the appropriate hose for a particular application and reduces the risk of cross-contamination. 9. **Static Dissipation:** - In applications where the transfer of chemicals may generate static electricity, chemical rubber hoses may include features to dissipate static charges, preventing the buildup of static electricity that could lead to sparks and potential hazards. 10. **Compliance Standards:** - Chemical hoses may need to comply with industry standards and regulations to ensure their safety and performance. Compliance with standards helps guarantee that the hose meets certain quality and safety requirements. 11. **Abrasion Resistance:** - Depending on the application, chemical hoses may be designed to resist abrasion, ensuring a longer service life, especially in environments where the hose may come into contact with abrasive materials. Choosing the right chemical rubber hose involves considering the specific requirements of the application, including the types of chemicals involved, temperature and pressure conditions, and other environmental factors. Consulting with manufacturers or industry experts can help ensure the selection of a hose that meets the necessary criteria for safety and performance.

- Style

- Plain and Corrugated Top

- Product Type

- Chemical Rubber Hose

- Ash %

- 5% Max

- Color

- Black

- Natural Rubber

- EPDM and Nitrile Rubber

IS:7654 Chemical Rubber Hose Trade Information

- Minimum Order Quantity

- 100 Meter

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 1000 Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Standard packing as per Dimension

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About IS:7654 Chemical Rubber Hose

Chemical rubber hoses are specialized hoses designed to handle various types of chemicals, acids, and corrosive materials in industrial applications. These hoses are constructed with materials that provide resistance to the specific chemicals they are intended to convey, ensuring safety and reliability in the transfer of potentially hazardous substances. Here are some key features and considerations related to chemical rubber hoses:

1. Material Compatibility

- Chemical hoses are made from rubber compounds that are resistant to the specific chemicals they will come into contact with. Common rubber materials used include EPDM (ethylene propylene diene monomer), UHMW (ultra-high molecular weight) polyethylene, and FKM (fluoroelastomer).

2. Reinforcement

- Chemical hoses often have reinforcement layers to enhance their strength and durability. Reinforcements may include textile fabrics, wire helixes, or other materials depending on the application.

3. Chemical Resistance

- The primary characteristic of chemical rubber hoses is their resistance to the corrosive effects of chemicals. Hoses are designed to withstand exposure to acids, bases, solvents, and other aggressive substances without degradation.

4. Temperature Range

- Chemical hoses are designed to operate within specific temperature ranges, ensuring that they remain effective and stable in a variety of working conditions.

5. Pressure Ratings

- Hoses are rated for different pressure levels to accommodate various industrial processes. It's crucial to select a hose with a pressure rating suitable for the intended application.

6. Flexibility

- Chemical hoses need to be flexible to facilitate easy handling and installation in different industrial environments. The flexibility is especially important when the hose is used in confined spaces or when connecting to equipment.

7. End Connections

- Chemical hoses typically have end connections, such as flanges or couplings, that allow them to be securely attached to equipment or other hoses in the system.

8. Applications

- Chemical rubber hoses are used in a wide range of industries, including chemical manufacturing, petrochemicals, pharmaceuticals, water treatment, and more. They are employed for the transfer of acids, alkalis, solvents, and other corrosive substances.

9. Color Coding

- Some chemical hoses are color-coded to help users quickly identify their compatibility with specific types of chemicals. This can enhance safety and prevent the accidental mixing of incompatible substances.

10. Compliance Standards

- Chemical hoses may need to comply with industry standards and regulations to ensure their safety and performance. Checking for certifications or approvals from relevant authorities is essential.

When selecting a chemical rubber hose, it's crucial to consider the specific chemicals it will come into contact with, as well as the operating conditions of the intended application. Consulting with manufacturers or experts in industrial hoses can help ensure the right hose is chosen for the specific needs of a given process or industry.

Superior Chemical Resistance

Constructed with EPDM and nitrile rubber, the IS:7654 chemical hose resists a broad spectrum of corrosive media, including acids and solvents. Its material composition ensures the hose maintains functionality and safety during chemical transfer, making it indispensable in harsh industrial environments.

Versatile Style Options

Available in both plain and corrugated styles, this hose addresses diverse installation needs. The corrugated design improves flexibility, aiding maneuverability in tight spaces, while the plain variant delivers robust structural integrity. Both styles help facilitate easy connection and usage within chemical plants.

Compliance and Safety Assured

Manufactured to IS:7654 standards, the hose carries a maximum ash content of 5%, ensuring consistent quality. Users benefit from reliable performance, reduced risk of leaks, and long service life. Compliance assures suitability for dealers, fabricators, producers, and suppliers aligned with industry safety protocols.

FAQ's of IS:7654 Chemical Rubber Hose:

Q: How does the IS:7654 chemical rubber hose ensure safety during chemical transfer?

A: This hose is constructed with EPDM and nitrile rubber, providing outstanding resistance to chemical corrosion and minimizing the risk of leaks or failure during operations. Its robust design and compliance with IS:7654 standards further guarantee safe handling of hazardous substances.Q: What is the benefit of choosing a corrugated top style for this hose?

A: The corrugated top enhances flexibility, allowing for easier installation and movement in restricted or complex industrial environments. This design makes handling and routing the hose around equipment more convenient, without compromising durability.Q: When should I use the IS:7654 chemical rubber hose?

A: You should use this hose when transferring acids, corrosive chemicals, and solvents in industrial processes that require high chemical resistance and safety. It's suitable for use by manufacturers, traders, and suppliers dealing with hazardous materials.Q: Where can the IS:7654 chemical rubber hose be installed?

A: This hose can be installed in chemical plants, manufacturing units, and industrial sites across India where safe and reliable chemical conveyance is needed. Its versatility accommodates various connection types and operating environments.Q: What process ensures the hose meets quality standards?

A: The hose is produced following IS:7654 compliance protocols, which involve rigorous testing for ash content, chemical resistance, and structural integrity. These processes guarantee adherence to industry norms and optimal performance under demanding conditions.Q: How does the hose's material composition affect its chemical resistance?

A: EPDM and nitrile rubber are selected for their proven ability to withstand a wide range of acids and corrosive chemicals. This composition reduces degradation and ensures the hose remains effective and reliable throughout its service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

Bitumen Mastic Pad

Price 255 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage & Applications : Sound dampening, vibration isolation, flooring underlayment, bridge bearings, construction joints

Material : Bitumen Compound with Mineral Fillers

Size : Custom sizes available

Color : Black

DI pipe Gasket

Price 250.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Sealing joints between ductile iron pipes in water supply and sewage systems

Material : EPDM/Natural Rubber/SBR

Size : Available for pipe sizes DN 80 to DN 1200

Color : Black

Slurry Rubber Hose

Price 9000.0 INR / Number

Minimum Order Quantity : 1 Number

Usage & Applications : Slurry, mud, grit and sand conveying in mining, industrial, dredging and construction sites

Material : Natural rubber, synthetic rubber, reinforcement with textile or steel wire

Size : 2 inches to 16 inches (or as specified)

Color : Black with colored identification stripe

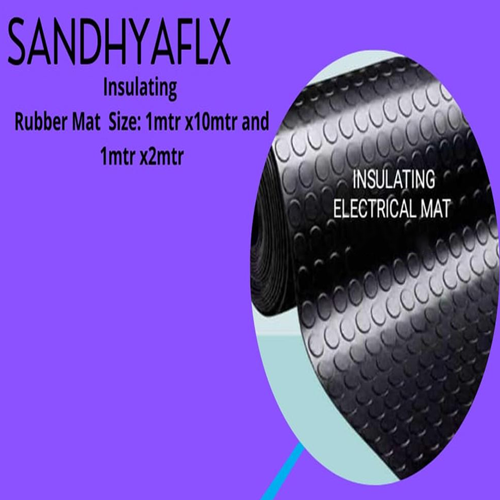

INSULATING RUBBER MAT 1X2 MTR 2MM THICKNESS

Price 400.0 INR / Meter

Minimum Order Quantity : 1 Meter

Usage & Applications : Used for providing insulation in electrical environments, control panels, substation flooring, and around electrical equipment to ensure safety against electric shocks.

Material : Highgrade natural and synthetic rubber compound

Size : 1 meter x 2 meter

Color : Black

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free