Expansion Joint Mastic Pad

Price 260 INR/ Piece

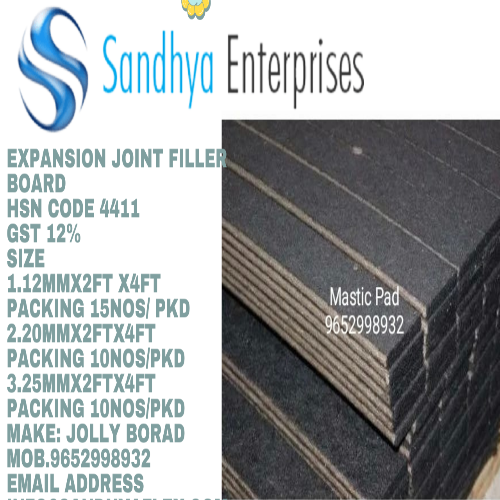

Expansion Joint Mastic Pad Specification

- Hardness

- 60 to 65 Shora A

- Feature

- Weather Resistance

- Resistance level

- Weather Resistance

- Thickness

- 12 to 25 Millimeter (mm)

- Color

- Black

- Product Type

- Mastic Pad

Expansion Joint Mastic Pad Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 4 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- SANDHYAFLEX Supplier of Expansion Joint Filler Board Thickness 12mm 20mm 25mm width 2Feet 600mm Lenght 4Feet 1200mm Packing 12mm 15nos/PKD 20mm and 25mm 10 Nos/PLD

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About Expansion Joint Mastic Pad

Expansion Joint Mastic Pad has a concrete casting in a slab form that offers an apt provision of contraction and expansion according to the variations in the temperature. It is broadly used in construction of bridges, decks, roads and runway. It is manufactured by our experts using high grade raw material and advanced machines as per international standards. Clients can avail from us this range of Expansion Joint Mastic Pad at most affordable prices.

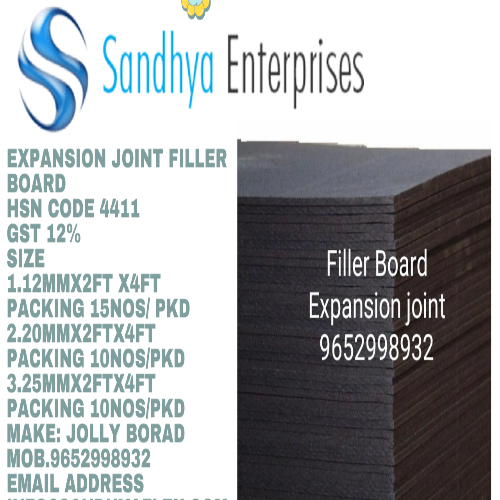

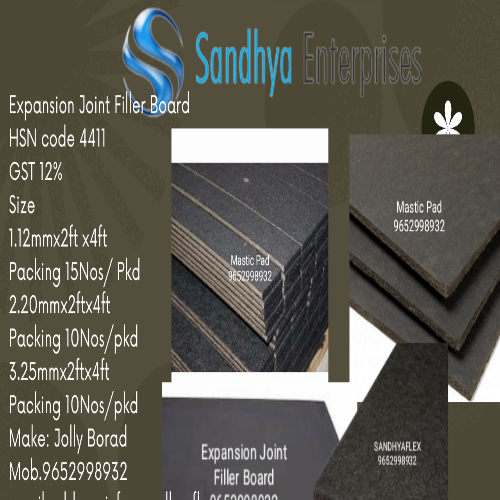

SANDHYAFLEX

Supplier of Expansion Joint Filler Board

Thickness

12mm

20mm

25mm

width 2Feet 600mm

Lenght 4Feet 1200mm

Packing

12mm 15nos/PKD

20mm and 25mm 10 Nos/PLD

Exceptional Weather Resistance

Our Expansion Joint Mastic Pads offer consistent performance even in extreme weather conditions, ensuring long-term durability. The carefully engineered material composition shields expansion joints from moisture, temperature variations, and external elements, making it ideal for both indoor and outdoor construction use.

Versatile Thickness and Hardness Ranges

Available in thicknesses from 12 to 25 millimeters and a hardness level of 60 to 65 Shora A, the mastic pad suits diverse requirements. Whether you need flexibility or toughness for infrastructure projects, theres an option tailored for your specific application.

FAQs of Expansion Joint Mastic Pad:

Q: How is the Expansion Joint Mastic Pad used in construction projects?

A: The mastic pad is placed between structural elements to absorb movement, prevent cracking, and provide a weather-resistant barrier in construction and infrastructure applications.Q: What benefits does the Expansion Joint Mastic Pad offer?

A: It provides excellent weather resistance, long-term durability, and protects expansion joints from moisture, temperature changes, and surface degradation, supporting structural integrity.Q: What is the recommended thickness and hardness of the mastic pad for typical use?

A: The pad is available in thicknesses from 12 to 25 mm with a hardness of 60 to 65 Shora A, making it suitable for most building and infrastructure expansion joint requirements.Q: Where can I purchase these mastic pads in India?

A: They are available through a wide network of dealers, fabricators, manufacturers, producers, retailers, suppliers, traders, and wholesalers across various regions of India.Q: What is the installation process for the Expansion Joint Mastic Pad?

A: Installation involves cleaning the joint surface, aligning the mastic pad to the joint, and securing it firmlyeither with adhesive or by fitting it between the elements per project specifications.Q: When should the Expansion Joint Mastic Pad be replaced?

A: Replacement is recommended if there are signs of significant wear, cracks, or loss of elasticity, typically identified during routine maintenance checks or refurbishment projects.Q: How does the black color of the pad contribute to its functionality?

A: The black color helps reduce visible dirt accumulation and provides UV resistance, prolonging the pads life in outdoor installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

Conductive Rubber Sheet

Price 350 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Conductive Rubber Sheet

Color : Black

Feature : Weather and Heat Resistance

Natural Rubber : Synthetic Blend / Natural Rubber available

Mastic Pad

Price 350 INR / Piece

Minimum Order Quantity : 25 Pieces

Product Type : Mastic Pad

Color : Black

Feature : Flexible, Nonbrittle, Easy to install, Weatherresistant

Natural Rubber : Contains natural bitumen and fillers

Rubber Strip for Strip Seal Expansion Joint

Price 500 INR / Meter

Minimum Order Quantity : 100

Product Type : Strip

Color : Black

Feature : Weather and Ozon Resistance

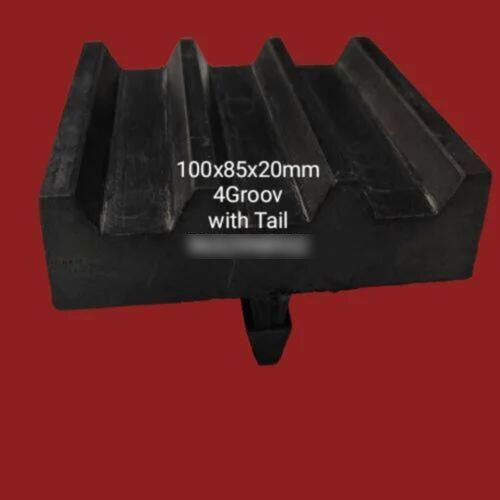

Groove Rubber Pad

Price 35.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Product Type : Groove Rubber Pad

Color : Black

Feature : The features of EPDM groove pads make them wellsuited for various applications in construction, infrastructure, and engineering projects. Here are some key features of EPDM groove pads: 1. **Resilience**: EPDM groove pads exhibit excellent resilience, allowing them to recover their original shape after deformation. This resilience enables them to withstand repetitive loading, compression, and movement without permanent damage, ensuring longterm performance and durability. 2. **Flexibility**: EPDM groove pads are highly flexible, allowing them to accommodate movement, vibration, and thermal expansion in structures and mechanical systems. Their flexibility makes them suitable for use in expansion joints, bridge bearings, and other applications where dynamic movement is expected. 3. **Weather Resistance**: EPDM groove pads offer exceptional resistance to weathering, UV radiation, ozone exposure, and extreme temperatures. They maintain their mechanical properties and sealing effectiveness over a wide range of environmental conditions, making them ideal for outdoor applications. 4. **Chemical Resistance**: EPDM groove pads are resistant to a wide range of chemicals, oils, solvents, and acids, ensuring compatibility with various construction materials and environments. They provide reliable sealing and protection against corrosion, degradation, and chemical attack in aggressive industrial settings. 5. **Waterproofing**: EPDM groove pads possess excellent waterproofing properties, forming a tight seal to prevent water ingress and moisture penetration in building joints, pipeline supports, and other critical areas. They help maintain the integrity and longevity of structures by preventing waterrelated damage and deterioration. 6. **Noise and Vibration Reduction**: EPDM groove pads serve as effective vibration isolators and noise dampeners in machinery mounts, railway tracks, and building construction applications. They absorb and dissipate energy, reducing noise transmission, structural resonance, and equipment wear, improving overall performance and comfort. 7. **NonConductivity**: EPDM groove pads are nonconductive and electrically insulating, making them suitable for use in electrical installations, railway tracks, and other applications where electrical isolation is required. They help prevent electrical shock hazards and interference in sensitive equipment and systems. 8. **Ease of Installation**: EPDM groove pads are lightweight, easy to handle, and simple to install using standard tools and techniques. They can be cut, shaped, and bonded to various surfaces, reducing installation time and labor costs in construction and maintenance projects. Overall, the features of EPDM groove pads, including resilience, flexibility, weather resistance, chemical resistance, waterproofing, noise and vibration reduction, nonconductivity, and ease of installation, make them versatile and reliable solutions for a wide range of applications in diverse industries.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS