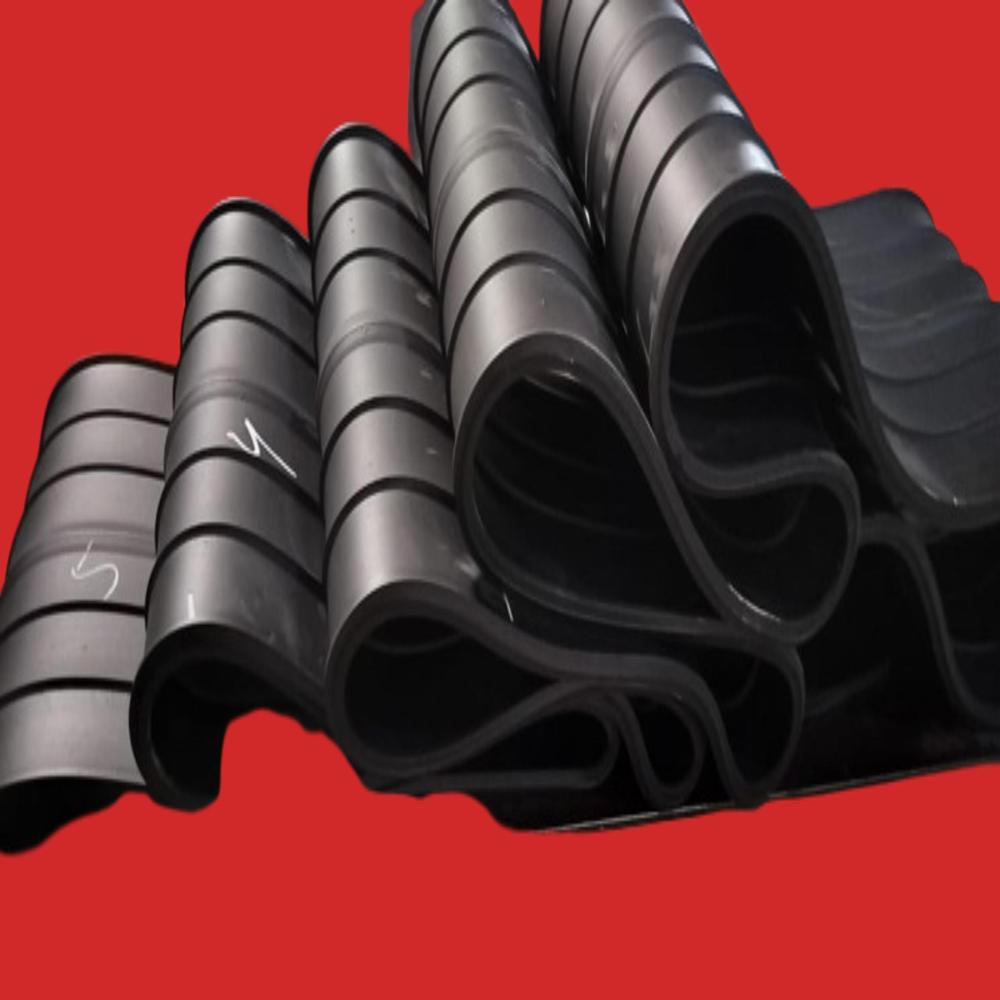

PVC Water Stopper

Price 80 INR/ Meter

PVC Water Stopper Specification

- Usage

- Sandhya Enterprises are one of the top manufacturers in India. Water Stoppers are the flexible plastic strips that are used to provide a physical barrier to water. The barriers can be at concrete joints in basements, water-retaining structures like water tanks, swimming pools, structural foundations and other constructions of below ground level. Water stoppers are also known as water bars and seal construction joints. In a typical water stopper, there are two identical halves on both sides of the central bulb. They serve as an additional extension aiming to increase the path length for water entering behind the edge of water stopper. Compounding of PVC Water Stopper Anti-ageing customized plastic compound is used for manufacturing the water stoppers. Alongside, it has PVC as a base polymer. Moreover, the properties it exhibit are high elasticity and tensile strength, immunity to corrosion, excellent weather resistance, unaffected by acids, alkalis, metals, salts and other chemicals. Other properties include lower water absorption, high hydrostatic pressure withstanding capacity, heavy turbine shock bearing alongside earthquakes and floods. Application in construction industry The PVC water stopper acts as a sealant at RCC Masonry concrete joints alongside preventing any water seepage through the joints.

- Material

- Poly Vinyl Chaloride

- Type

- Center Bulb

- Size

- 150,200x230,240,250 and 300

- Application

- Sandhya Enterprises are one of the top manufacturers in India. Water Stoppers are the flexible plastic strips that are used to provide a physical barrier to water. The barriers can be at concrete joints in basements, water-retaining structures like water tanks, swimming pools, structural foundations and other constructions of below ground level. Water stoppers are also known as water bars and seal construction joints. In a typical water stopper, there are two identical halves on both sides of the central bulb. They serve as an additional extension aiming to increase the path length for water entering behind the edge of water stopper. Compounding of PVC Water Stopper Anti-ageing customized plastic compound is used for manufacturing the water stoppers. Alongside, it has PVC as a base polymer. Moreover, the properties it exhibit are high elasticity and tensile strength, immunity to corrosion, excellent weather resistance, unaffected by acids, alkalis, metals, salts and other chemicals. Other properties include lower water absorption, high hydrostatic pressure withstanding capacity, heavy turbine shock bearing alongside earthquakes and floods. Application in construction industry The PVC water stopper acts as a sealant at RCC Masonry concrete joints alongside preventing any water seepage through the joints.

- Hardness

- 68 Shore A

- Feature

- Waterproof

PVC Water Stopper Trade Information

- Minimum Order Quantity

- 100 Meter

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- 1000 Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Export Packing Date:02.09.2023 Dimension in CBM PVC Water Stopper with Center Bulb Each Roll 25Mtr SR No Dimension Length Width Height CBM Weight kg/Roll 1 150x5mm 0.625 0.625 0.150 0.059 40 2 150x6mm 0.625 0.625 0.150 0.059 45 3 150x8mm 0.625 0.625 0.150 0.059 55 4 200x8mm 0.625 0.625 0.200 0.059 60 5 200x10mm 0.65 0.65 0.200 0.078 64 6 225x5mm 0.625 0.625 0.23 0.090 65 7 225x6mm 0.625 0.625 0.230 0.090 70 8 225x8mm 0.65 0.65 0.230 0.097 90 9 225x10mm 0.65 0.65 0.230 0.097 100 10 240x8mm 0.65 0.650 0.240 0.104 110 11 240x10mm 0.650 0.650 0.240 0.104 125 12 250x8mm 0.675 0.675 0.250 0.114 95 13 250x10mm 0.675 0.675 0.250 0.114 115 14 300x6mm 0.700 0.700 0.300 0.147 95 15 300x8mm 0.725 0..725 0.300 0.158 115 16 300x10mm 0.750 0.750 0.300 0.169 140 17 300x12mm 0.775 0.775 0.300 0.18 140 18 300x15mm 0.800 0.800 0.300 0.192 160 Kiker Type 19 230x4mm 0.625 0.625 0.230 0.090 67 Dumbbell Type 20 230x8mm 0.650 0.650 0.230 0.097 87 21 230x10mm 0.650 0.650 0.230 0.097 100

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About PVC Water Stopper

Sandhya Enterprises are one of the top manufacturers in India. Water Stoppers are the flexible plastic strips that are used to provide a physical barrier to water. The barriers can be at concrete joints in basements, water-retaining structures like water tanks, swimming pools, structural foundations and other constructions of below ground level. Water stoppers are also known as water bars and seal construction joints. In a typical water stopper, there are two identical halves on both sides of the central bulb. They serve as an additional extension aiming to increase the path length for water entering behind the edge of water stopper.

Compounding of PVC Water Stopper

Anti-ageing customized plastic compound is used for manufacturing the water stoppers. Alongside, it has PVC as a base polymer. Moreover, the properties it exhibit are high elasticity and tensile strength, immunity to corrosion, excellent weather resistance, unaffected by acids, alkalis, metals, salts and other chemicals. Other properties include lower water absorption, high hydrostatic pressure withstanding capacity, heavy turbine shock bearing alongside earthquakes and floods.

Application in construction industry

- The PVC water stopper acts as a sealant at RCC Masonry concrete joints alongside preventing any water seepage through the joints.

-

-

- A PVC water stopper is a type of construction material used to prevent the passage of water through joints or gaps in structures such as concrete walls, floors, or basements. It is commonly used in applications where water leakage needs to be controlled or prevented, such as in swimming pools, water tanks, tunnels, or underground structures.

- PVC water stoppers are made from polyvinyl chloride (PVC), a durable and flexible plastic material. They are designed in various shapes and sizes to accommodate different joint configurations and construction requirements. The most common types of PVC water stoppers include:

- 1. Straight Water Stopper: This type of water stopper is used in straight joints or construction joints where two concrete sections meet. It provides a barrier against water infiltration.

- 2. Internal and External Corners: These water stoppers are specifically designed to fit into the internal and external corners of joints, ensuring a watertight seal at these critical areas.

- 3. Bulb-Type Water Stopper: This water stopper features a bulbous shape that provides additional flexibility and sealing capacity. It is suitable for applications where joints are subject to movement or expansion.

- 4. Ribbed Water Stopper: Ribbed water stoppers have a ribbed surface that enhances the grip and bonding with concrete. This type of water stopper offers excellent sealing capabilities and is commonly used in high-pressure water applications.

- PVC water stoppers are typically installed during the concrete pouring process. They are embedded within the joints, ensuring a secure and watertight seal. The flexibility of PVC allows the water stopper to accommodate movement or settling of the surrounding structures without compromising its sealing properties.

- It is important to follow the manufacturer's guidelines and consult with a qualified engineer or contractor for the appropriate selection and installation of PVC water stoppers based on the specific project requirements.

Advanced Waterproofing Solution

PVC Water Stoppers with a center bulb design provide robust water resistance for construction joints. The unique central bulb structure increases the length of the seepage path, ensuring water is effectively blocked from passing through critical concrete junctions.

Engineered for Durability

Manufactured using a custom anti-ageing PVC compound, these water stoppers possess high elasticity, respond excellently to structural movement, and are highly resistant to weather, chemicals, and physical shock. They are designed to remain effective even during heavy flooding or seismic activity.

Versatile Construction Applications

Suitable for use in basements, water tanks, swimming pools, and other below-ground structures, the PVC Water Stopper is an essential component in water-retaining construction. Its flexible installation options make it a preferred choice among contractors and builders across various industries.

FAQ's of PVC Water Stopper:

Q: How does the center bulb design in a PVC Water Stopper enhance waterproofing?

A: The center bulb in a PVC Water Stopper serves as an additional extension, increasing the path that water must travel to penetrate the joint. This design helps to effectively prevent seepage by creating a more formidable barrier within construction joints.Q: What is the typical usage process for installing a PVC Water Stopper in construction?

A: PVC Water Stoppers are embedded within concrete at joints during construction, such as in basements or tanks. The stopper is placed between concrete pours to seal the joint and prevent water passage, ensuring persistent watertight integrity as the structure sets.Q: Where are PVC Water Stoppers commonly used?

A: These water stoppers are widely used in water-retaining structures like swimming pools, water tanks, basements, structural foundations, and any construction below ground level where water ingress is a concern.Q: What are the main benefits of using PVC Water Stoppers from Sandhya Enterprises?

A: Benefits include high elasticity, excellent tensile strength, immunity to corrosion, weather resistance, and chemical stability. They also withstand hydrostatic pressure, heavy vibrations, and shocks from flooding or earthquakes, offering long-term waterproofing performance.Q: When should a PVC Water Stopper be used during the construction process?

A: A PVC Water Stopper should be installed at the time of casting concrete, particularly at the junctions of construction joints. Early installation ensures a continuous seal and optimal waterproofing efficiency for the structure over time.Q: What makes the material composition of these water stoppers suitable for harsh environments?

A: Manufactured from an anti-ageing custom PVC compound, these stoppers resist acids, alkalis, salts, and most chemicals, while their low water absorption and robust physical properties prepare them to endure challenging site conditions and environmental stressors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Water Stopper Category

Dumbell Type PVC Water Stopper

Price 100 INR / Meter

Minimum Order Quantity : 100

Hardness : 65 Shore

Application : Selection of appropriate PVC water stopper Ribbed Type It has a multipurpose water stopper design to be used for the expected differential settlement of poured concrete and a firm concrete grip desired. Dumbbell Type With greater variation in temperature, expansion and contraction of joints happen. Dumbbell type water stoppers are the suggested ones for these cases. Kicker (Surface Type) Where the embedded types cannot be used owing to interference of steel reinforcement, these are placed externally. Installation procedure: During installation, using small wires, the water stoppers are tied to the steel framework through the eyelets. Also, certain metal clamps are used to grip the water stop seal and keep it in proper position. Initially, half of the water stopper is places in the concrete. It leaves the other half extended. Then, the other half is embedded that leaves the centre bulb free for expansion and contraction movements. Applications Of PVC Water Stoppers Public Utilities: For bridges, road embankments, tunnels, water tanks, water filtration systems, swimming pools, sewage plants, clarifiers, dams, canals, reservoirs, aqueducts and irrigation projects cooling towers. Buildings: For basements, foundations slabs, masonry joints, retaining walls, terraces, overhead & underground water tanks and Industries: For fertilizer steel, chemical plants, waste treatment plants, atomic reactors, thermal & hydro power stations and shipyard & docks. Precautions to take while water stopper installation They are vulnerable to damage during the construction process The concrete compaction around the water stopper should be taken care of. If not, it can dislocate and lead to a risk of honeycomb formation. This might result in leakage through concrete instead of the joint. Methods for joining PVC water stoppers with heater blade Water stoppers can be joined on the site using a simple electrical heater blade. Water bars having the same width and design should be sharply levelled with a knife at the Turn on the Electric Heater Blade. Wait till it becomes hot Place the water stopper on both sides of heater blade. Press it until it melts but without burning Remove the heater blade upward Join the molten ends quickly. Hold them together firmly for approximately 20 to 30 seconds.

Material : Poly Vinyl Chaloride

Type : Dumbell Tyoe

PVC Water stopper 150*10mm

Price 120.00 INR / Meter

Minimum Order Quantity : 1 Meter

Hardness : Medium

Application : PVC Water stopper

Material : PVC

300mm PVC water stopper

Price 230.0 INR / Meter

Minimum Order Quantity : 1 Meter

Hardness : 6575 Shore A

Application : Used in Concrete Structures for Water Seepage Control

Material : Polyvinyl Chloride (PVC)

Type : Center Bulb Type

Electrical Bled Heater PVC Water Stopper Jointing

Price 3600.0 INR / Number

Minimum Order Quantity : 1 Number

Hardness : 6580 Shore A

Application : Construction Joints, Expansion Joints, Swimming Pools, Water Tanks

Material : PVC (Polyvinyl Chloride)

Type : Electrical Bled Heater Water Stopper

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free