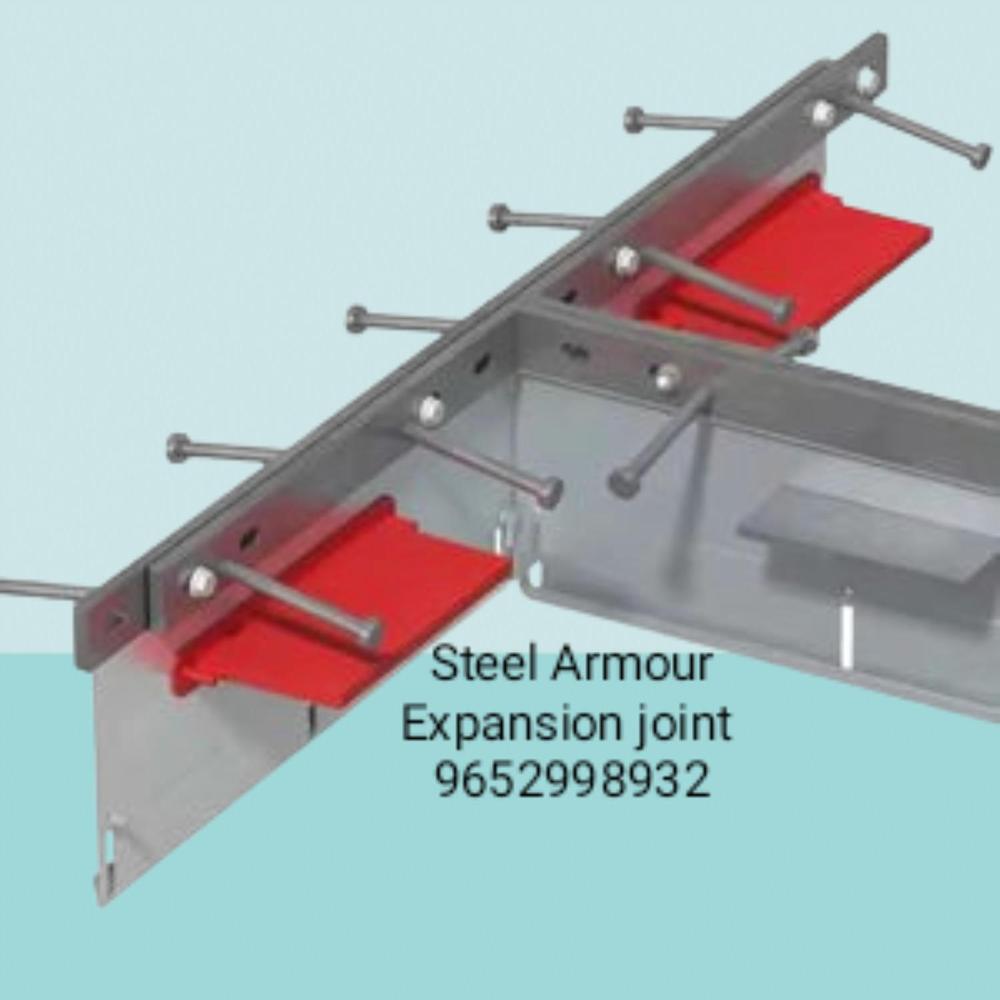

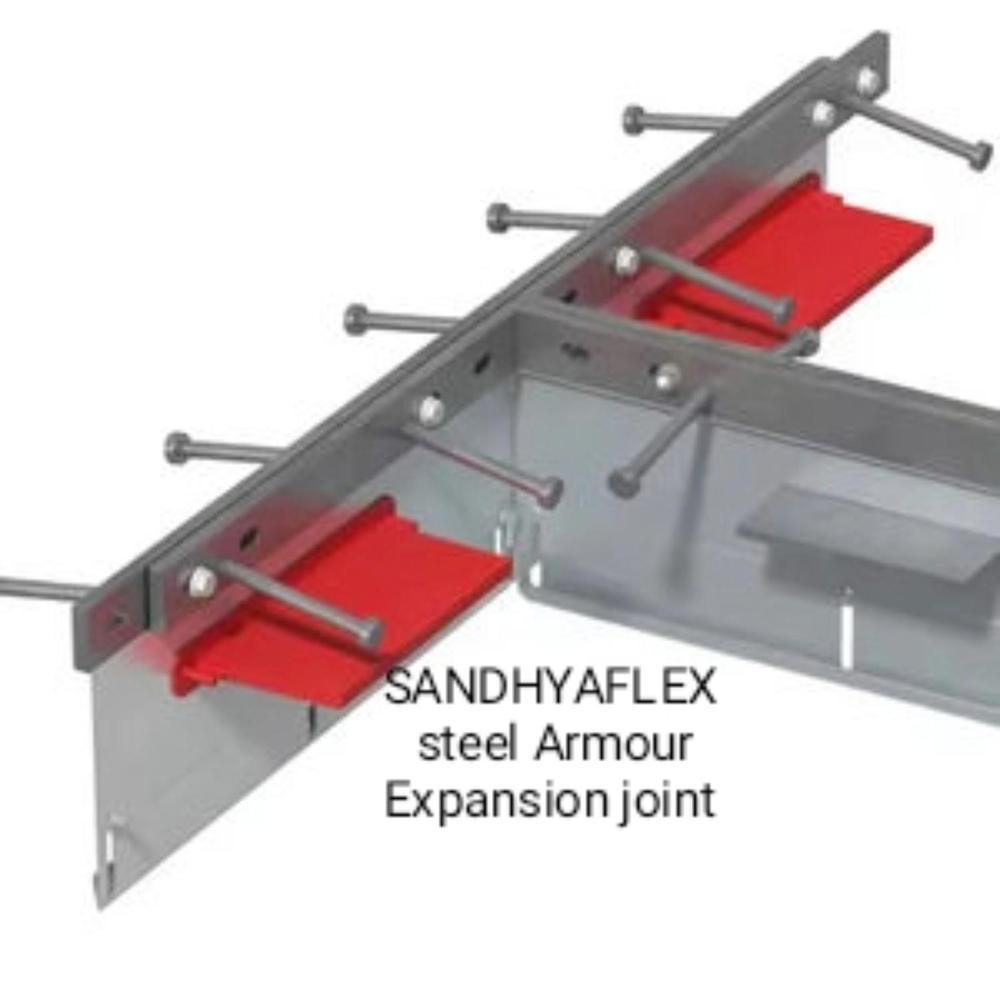

Steel Amour Expansion Joint

Price 2000.00 INR/ Meter

Steel Amour Expansion Joint Specification

- Display Type

- No

- Thickness

- 10 Millimeter (mm)

- Material

- Mild Steel

- Color

- Silver

- Usage

- Industrial

- Size

- Standard

About Steel Amour Expansion Joint

A steel armor expansion joint is a type of flexible joint designed to absorb movement, vibration, and thermal expansion in pipelines, machinery, and structural systems. These joints are typically used in environments where pipes, ducts, or other components undergo significant expansion and contraction due to temperature changes, pressure fluctuations, or mechanical stress. The steel armor in these expansion joints provides added strength, durability, and protection, ensuring that the system remains intact and functions efficiently even in challenging conditions.

Key Features of a Steel Armor Expansion Joint:

-

Steel Armor Construction:

-

The primary distinguishing feature of a steel armor expansion joint is the use of steel in its construction. The steel armor provides extra reinforcement and protection to the flexible bellows or elastomeric material that is used to absorb movement. It helps resist external forces such as pressure surges, physical impact, and environmental factors.

-

-

Flexibility:

-

The main purpose of an expansion joint is to absorb movement and expansion caused by thermal changes, pressure variations, and mechanical stress. Steel armor expansion joints are designed to offer significant flexibility while maintaining their strength and integrity under high-pressure or high-temperature conditions.

-

-

Durability and Strength:

-

The steel armor serves as a protective outer layer, ensuring that the expansion joint is resistant to mechanical wear and tear, abrasion, and external impacts. This makes the joint suitable for use in harsh industrial environments, where equipment is subjected to heavy physical stress.

-

-

Pressure Resistance:

-

Steel armor expansion joints are specifically designed to withstand high-pressure systems. They can handle a range of pressures, depending on the design and materials used. This makes them ideal for use in steam lines, chemical pipelines, and other high-pressure systems.

-

-

Temperature Resistance:

-

These joints are also designed to handle extreme temperatures, both hot and cold. The bellows or elastomeric material used within the joint is typically made from materials that can withstand high temperatures without losing flexibility or integrity. The steel armor provides additional protection from thermal stresses.

-

-

Corrosion Resistance:

-

Steel armor expansion joints are often coated or made from corrosion-resistant materials to prevent degradation due to exposure to moisture, chemicals, or environmental elements. This ensures the longevity and reliability of the joint, particularly in industries where corrosive substances are present.

-

Applications of Steel Armor Expansion Joints:

-

Pipelines:

-

Steel armor expansion joints are commonly used in pipelines to absorb thermal expansion and contraction, allowing the pipe to move without causing damage to the system. They are especially useful in large industrial pipelines, such as those in power plants, oil refineries, and chemical plants.

-

-

HVAC Systems:

-

In HVAC systems, steel armor expansion joints are used to absorb the movement caused by temperature changes in ducts and air handling systems. They prevent damage to the ductwork and reduce vibration that could affect system performance.

-

-

Boilers and Steam Systems:

-

Boilers and steam pipelines experience significant thermal expansion and pressure fluctuations. Steel armor expansion joints are used in these systems to maintain integrity and prevent leaks or failure due to thermal and mechanical stresses.

-

-

Turbines and Engines:

-

Expansion joints are often used in turbines and engines to handle the movement caused by thermal expansion and vibration. The steel armor provides extra protection in these high-stress environments.

-

-

Oil and Gas Industry:

-

Steel armor expansion joints are widely used in the oil and gas industry, where pipelines and equipment experience constant pressure, thermal fluctuations, and the potential for corrosion. These joints help maintain safe and efficient operations by absorbing the movement and protecting the system.

-

-

Chemical Plants:

-

In chemical plants, steel armor expansion joints are used to handle the movement of pipes and ducts carrying hot, pressurized chemicals. The steel armor protects the joint from chemical exposure and physical damage, while the flexible bellows inside accommodate thermal and pressure changes.

-

-

Marine Applications:

-

Expansion joints are also used in marine applications, such as in ship pipelines and equipment, to absorb the movement caused by waves, thermal expansion, and pressure changes.

-

Advantages of Steel Armor Expansion Joints:

-

Enhanced Durability:

-

The steel armor protects the expansion joint from mechanical damage, physical impacts, and external wear and tear, making it ideal for use in industrial environments where robustness is critical.

-

-

High Pressure and Temperature Resistance:

-

Steel armor expansion joints are capable of withstanding high pressure and extreme temperatures, making them suitable for demanding applications like steam lines, chemical pipelines, and high-temperature industrial processes.

-

-

Protection from External Elements:

-

The steel armor provides protection against abrasion, external impacts, and corrosion, ensuring the longevity of the expansion joint in harsh environments.

-

-

Increased Flexibility:

-

Despite their steel construction, these joints maintain a high degree of flexibility, allowing them to absorb movement caused by thermal expansion, vibration, and other mechanical forces. This flexibility ensures that the system can maintain its structural integrity under varying conditions.

-

-

Customization:

-

Steel armor expansion joints can be customized in terms of size, shape, and material composition to meet the specific needs of an application. This allows for tailored solutions that provide the most effective sealing and movement absorption for different systems.

-

-

Cost-Effectiveness:

-

By protecting systems from damage and reducing the need for frequent repairs, steel armor expansion joints can help save on maintenance costs in the long term. They are a durable and reliable solution for systems that require movement compensation.

-

Maintenance and Care:

-

Inspection:

-

Regular inspection of steel armor expansion joints is essential to ensure that they are functioning properly. Signs of damage, such as cracks, excessive wear, or corrosion, should be addressed immediately to prevent system failure.

-

-

Cleaning:

-

Keeping the joint clean of debris and contaminants is important for maintaining its performance. The steel armor should be inspected for rust or corrosion and cleaned as necessary to ensure it remains protective.

-

-

Replacement:

-

Over time, expansion joints may need to be replaced, especially if they have been subjected to extreme conditions that cause deterioration. It is essential to replace the joints at the right time to avoid leaks, system failures, or other issues.

-

Conclusion:

A steel armor expansion joint is a critical component in systems that experience thermal expansion, pressure changes, or mechanical movement. The steel armor provides additional protection to the flexible core of the joint, ensuring that it remains durable and effective in high-pressure and high-temperature applications. These joints are widely used in industries such as power generation, chemical processing, HVAC systems, and oil and gas pipelines to maintain system integrity, absorb movement, and reduce the risk of leaks or failures.

Would you like more specific details on selecting the right type of steel armor expansion joint for your application, or do you need information on manufacturers or suppliers? Let me know how I can assist further!

Engineered for Industrial Performance

Steel Amour Expansion Joints are designed specifically for industrial settings where structural integrity and flexibility are paramount. Using durable mild steel, these expansion joints effectively absorb movement due to temperature changes, loads, or vibrations, ensuring the longevity of both the joint and the structure. With standard sizing and a robust 10 mm thickness, the product is suitable for a wide array of industrial installations.

Reliable Supply Chain Across India

Manufactured, fabricated, and supplied throughout India, these expansion joints benefit from a comprehensive supply network that includes dealers, retailers, wholesalers, and traders. Customers can expect consistent quality and on-time delivery, whether purchasing in bulk or tailored quantities, ensuring projects remain on schedule.

FAQ's of Steel Amour Expansion Joint:

Q: How are Steel Amour Expansion Joints typically installed in industrial applications?

A: Steel Amour Expansion Joints are installed at points where two concrete or metal surfaces meet and are subject to movement. A professional installer or fabricator will securely fix the joint using welding or mechanical fasteners, ensuring it can absorb and compensate for expansion, contraction, or vibration as required.Q: What are the key benefits of using mild steel in these expansion joints?

A: Mild steel offers a strong balance between durability and flexibility, making it ideal for absorbing industrial stresses. It provides excellent resistance to deformation, is easy to fabricate, and maintains its structural integrity over time, ensuring reliable performance in industrial settings.Q: When should an industrial facility consider installing expansion joints like these?

A: Expansion joints should be installed during new construction or renovation when structures are expected to experience thermal expansion, mechanical movement, or vibration. Early installation helps prevent future cracking, buckling, or structural damage due to movement.Q: Where can I source Steel Amour Expansion Joints in India?

A: These joints are available nationwide through various channels including manufacturers, suppliers, dealers, retailers, traders, and wholesalers. You can approach local industrial suppliers or contact the manufacturer directly for guidance on the nearest authorized distributor.Q: What is the typical process for ordering these expansion joints from a supplier in India?

A: To order, you can contact a local dealer or fabricator, provide your project's specifications, and request a quote. The supplier will confirm sizes and quantities, process your order, and arrange for delivery-often guiding you on installation and after-sales support.Q: How should these expansion joints be used for optimal performance?

A: For optimal performance, Steel Amour Expansion Joints should be positioned at regular intervals where movement is expected, and installed by trained professionals. Regular inspection and maintenance ensure their continued effectiveness and extend the service life of the underlying structure.Q: What makes these expansion joints suitable for tough industrial environments?

A: The use of 10 mm thick mild steel with a silver protective finish provides excellent resistance to wear and corrosion. Their strength, flexibility, and standard sizing make them ideal for managing movement and pressure in high-stress industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bridge Expansion Joint Category

Compression Rubber Seal

Price 450.00 INR / Meter

Minimum Order Quantity : 1 Meter

Thickness : 5 Millimeter (mm)

Material : EPDM(Ethylene Propylene Diene Monomer)

Color : Gray

Monolithic F Type Strip seal Expansion Joint

Price 140.00 INR / Meter

Minimum Order Quantity : 1 Meter

Thickness : 6 Millimeter (mm)

Material : Cast Steel

Color : Gray

Compression Rubber Seal

Price 450.0 INR / Meter

Minimum Order Quantity : 1 Meter

Thickness : 515 mm (customizable)

Material : EPDM Rubber

Color : Black

Structure : Flexible, Extruded

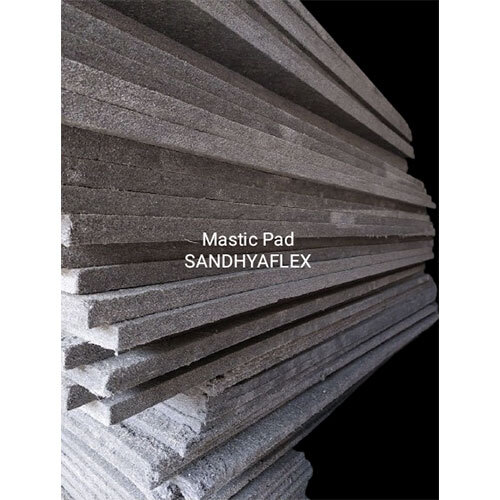

Industrial Expansion Joint Filler Board Road Construction

Price 380.0 INR

Minimum Order Quantity : 1

Thickness : 12 mm, 18 mm, 25 mm (custom sizes available)

Material : Bitumen Impregnated Fiberboard

Color : Dark Brown / Black

Structure : Compressed cellulose fiberboard with bitumen impregnation

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free