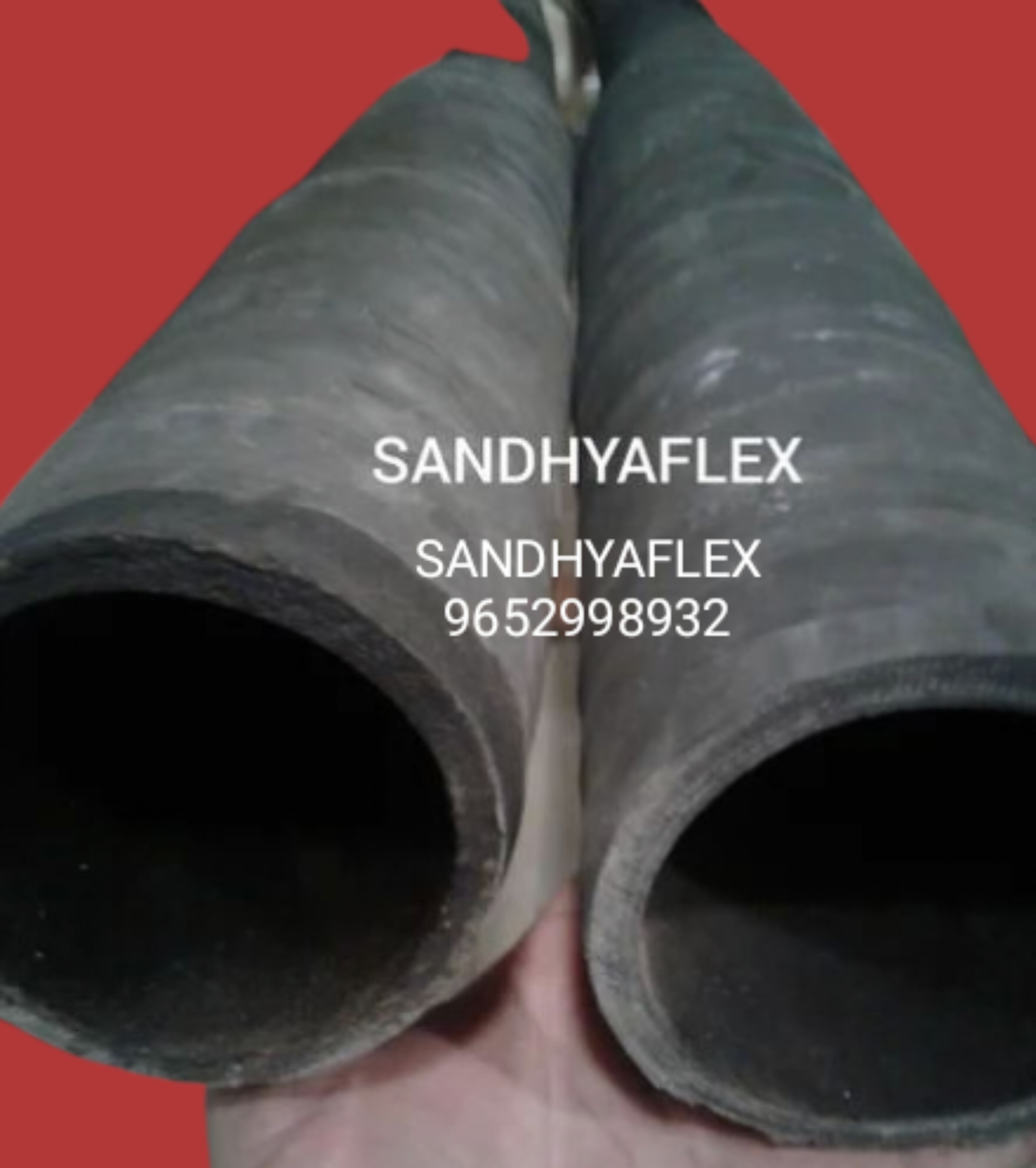

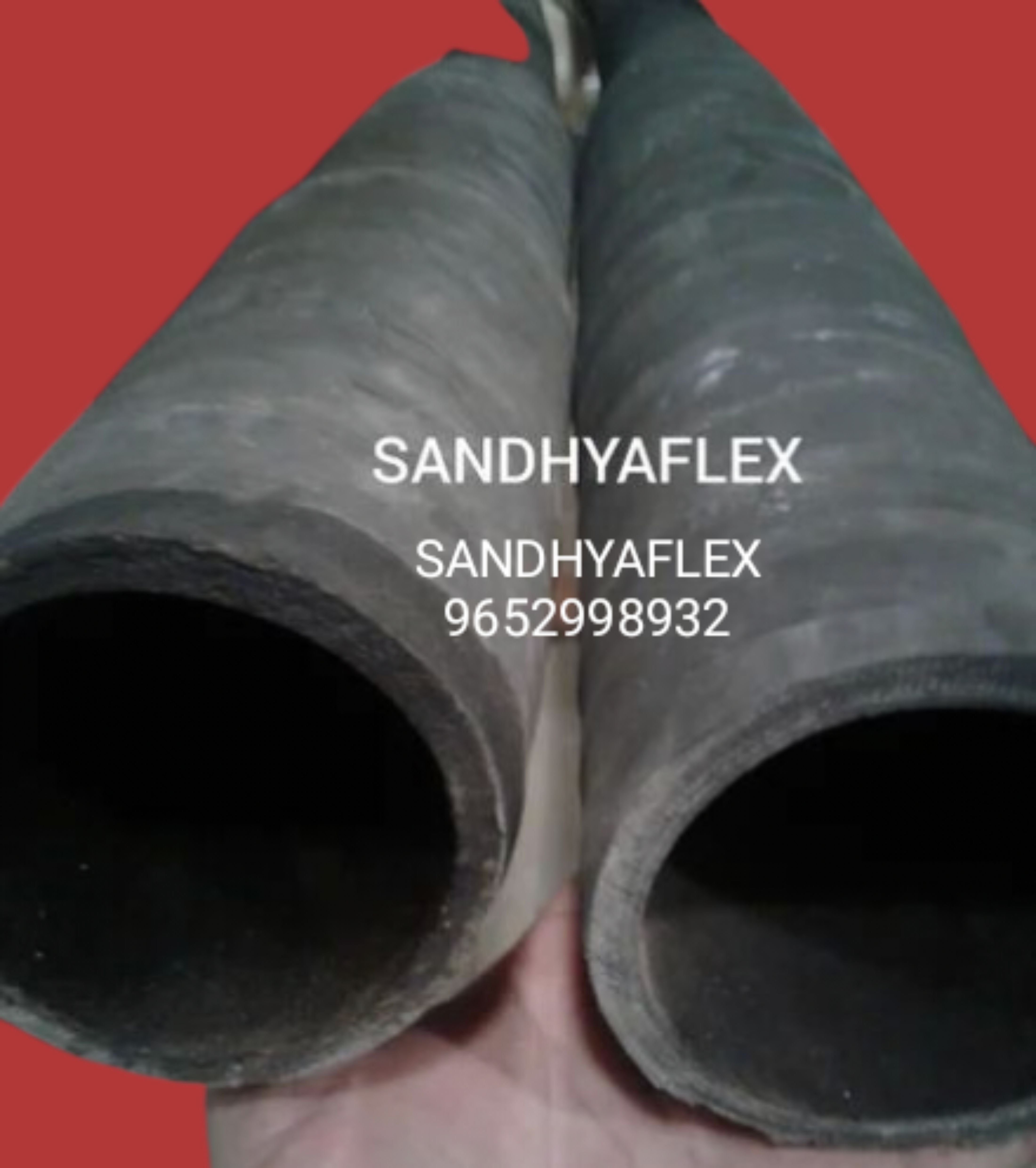

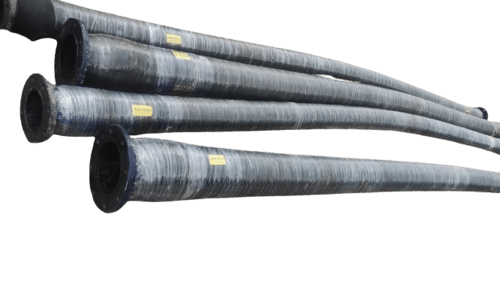

Oil Suction Rubber Hose

Price 1650.00 INR/ Meter

Oil Suction Rubber Hose Specification

- Connection Type

- MS Flance

- Hardness

- 60 to 65 Shore A

- Cover

- Rubber

- Medium

- Petroleum Oil

- Reinforcement

- Wire and Textile

- Shape

- Round Corrugate and Plain Top

- Usage

- Oil suction rubber hoses are specialized hoses designed for the transfer of oil, petroleum-based products, and other liquids with high oil content. They are commonly used in industrial, automotive, marine, and oilfield applications where reliable and efficient oil suction and discharge are required. Here are some key features, uses, and applications of oil suction rubber hoses: 1. **Construction**: Oil suction rubber hoses are typically constructed with an inner tube made of synthetic rubber resistant to oil and petroleum products. The inner tube is reinforced with high-strength textile or wire helix reinforcements to withstand vacuum pressure and prevent collapse during suction operations. The outer cover is also made of synthetic rubber resistant to abrasion, weathering, and oil exposure. 2. **Versatility**: Oil suction rubber hoses are versatile and can handle a wide range of fluids, including crude oil, diesel fuel, gasoline, hydraulic oil, lubricating oils, and various petroleum-based products. They are suitable for use in diverse industries such as oil and gas, automotive, chemical, mining, and agriculture. 3. **Suction and Discharge**: Oil suction rubber hoses are designed for both suction and discharge applications. They are used to transfer oil and petroleum products from storage tanks, trucks, ships, and offshore platforms to processing facilities, refineries, distribution terminals, and other destinations. They can also be used to remove oil spills and recover oil from water surfaces. 4. **Vacuum Resistance**: Oil suction rubber hoses are designed to withstand high vacuum pressures generated during suction operations. The reinforced construction prevents the hose from collapsing under vacuum, ensuring continuous fluid flow and efficient oil suction. 5. **Flexibility**: Oil suction rubber hoses offer flexibility and ease of handling, allowing them to bend and maneuver around obstacles without kinking or restricting fluid flow. This flexibility makes them suitable for use in tight spaces, confined areas, and applications requiring routing through complex piping systems. 6. **Temperature Resistance**: Oil suction rubber hoses are engineered to withstand a wide range of temperatures, from extreme cold to high heat. They can operate effectively in temperature ranges typically encountered in industrial environments, ensuring reliable performance in various weather conditions and climate zones. 7. **Chemical Resistance**: Oil suction rubber hoses are resistant to a variety of chemicals and solvents commonly found in petroleum-based products. They offer protection against degradation, swelling, and deterioration when exposed to oils, fuels, acids, alkalis, and other corrosive substances, ensuring long-term durability and reliability. 8. **Corrosion Resistance**: Oil suction rubber hoses are resistant to corrosion and degradation caused by exposure to saltwater, ozone, sunlight, and environmental contaminants. They are suitable for use in marine and offshore applications where exposure to harsh conditions is common. Overall, oil suction rubber hoses provide a reliable and efficient solution for the transfer of oil and petroleum products in a wide range of industrial, commercial, and marine applications. Their robust construction, flexibility, vacuum resistance, and chemical compatibility make them essential components in fluid handling systems where oil suction and discharge are required.

- Material

- Rubber

- Size

- 4

- Product Type

- Oil Rubber Hose

- Pressure

- 10 Bar

- Weight

- 8 to 12 Kilograms (kg)

- Color

- Black

- Length

- 15 Meter (m)

- Warranty

- 6 month

Oil Suction Rubber Hose Trade Information

- Minimum Order Quantity

- 100 Meter

- FOB Port

- mumbai

- Supply Ability

- 200 Per Day

- Delivery Time

- 10 Days

- Packaging Details

- Packing with HDPE Cover

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About Oil Suction Rubber Hose

Oil suction rubber hoses are specialized hoses designed for the transfer of oil, petroleum-based products, and other liquids with high oil content. They are commonly used in industrial, automotive, marine, and oilfield applications where reliable and efficient oil suction and discharge are required. Here are some key features, uses, and applications of oil suction rubber hoses:

1. Construction Oil suction rubber hoses are typically constructed with an inner tube made of synthetic rubber resistant to oil and petroleum products. The inner tube is reinforced with high-strength textile or wire helix reinforcements to withstand vacuum pressure and prevent collapse during suction operations. The outer cover is also made of synthetic rubber resistant to abrasion, weathering, and oil exposure.

2. Versatility Oil suction rubber hoses are versatile and can handle a wide range of fluids, including crude oil, diesel fuel, gasoline, hydraulic oil, lubricating oils, and various petroleum-based products. They are suitable for use in diverse industries such as oil and gas, automotive, chemical, mining, and agriculture.

3. Suction and Discharge Oil suction rubber hoses are designed for both suction and discharge applications. They are used to transfer oil and petroleum products from storage tanks, trucks, ships, and offshore platforms to processing facilities, refineries, distribution terminals, and other destinations. They can also be used to remove oil spills and recover oil from water surfaces.

4. Vacuum Resistance Oil suction rubber hoses are designed to withstand high vacuum pressures generated during suction operations. The reinforced construction prevents the hose from collapsing under vacuum, ensuring continuous fluid flow and efficient oil suction.

5. Flexibility Oil suction rubber hoses offer flexibility and ease of handling, allowing them to bend and maneuver around obstacles without kinking or restricting fluid flow. This flexibility makes them suitable for use in tight spaces, confined areas, and applications requiring routing through complex piping systems.

6. Temperature Resistance Oil suction rubber hoses are engineered to withstand a wide range of temperatures, from extreme cold to high heat. They can operate effectively in temperature ranges typically encountered in industrial environments, ensuring reliable performance in various weather conditions and climate zones.

7. Chemical Resistance Oil suction rubber hoses are resistant to a variety of chemicals and solvents commonly found in petroleum-based products. They offer protection against degradation, swelling, and deterioration when exposed to oils, fuels, acids, alkalis, and other corrosive substances, ensuring long-term durability and reliability.

8. Corrosion Resistance Oil suction rubber hoses are resistant to corrosion and degradation caused by exposure to saltwater, ozone, sunlight, and environmental contaminants. They are suitable for use in marine and offshore applications where exposure to harsh conditions is common.

Overall, oil suction rubber hoses provide a reliable and efficient solution for the transfer of oil and petroleum products in a wide range of industrial, commercial, and marine applications. Their robust construction, flexibility, vacuum resistance, and chemical compatibility make them essential components in fluid handling systems where oil suction and discharge are required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Rubber Hoses Category

Cement Feeding Rubber Hose With Flange

Price 1800 INR / Meter

Minimum Order Quantity : 100

Shape : Round

Material : Rubber

Color : Black

Water Suction Rubber Hose

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Shape : Round

Material : Rubber

Inside Diameter : 150 mm

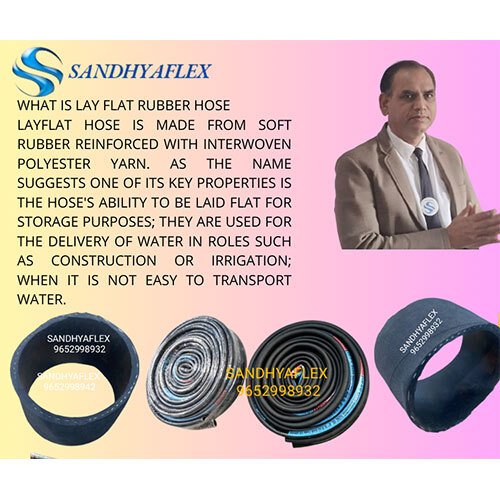

Lay Flat Rubber Hose

Price 450.00 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : Round

Material : Rubber

Color : Black

Inside Diameter : 690 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free