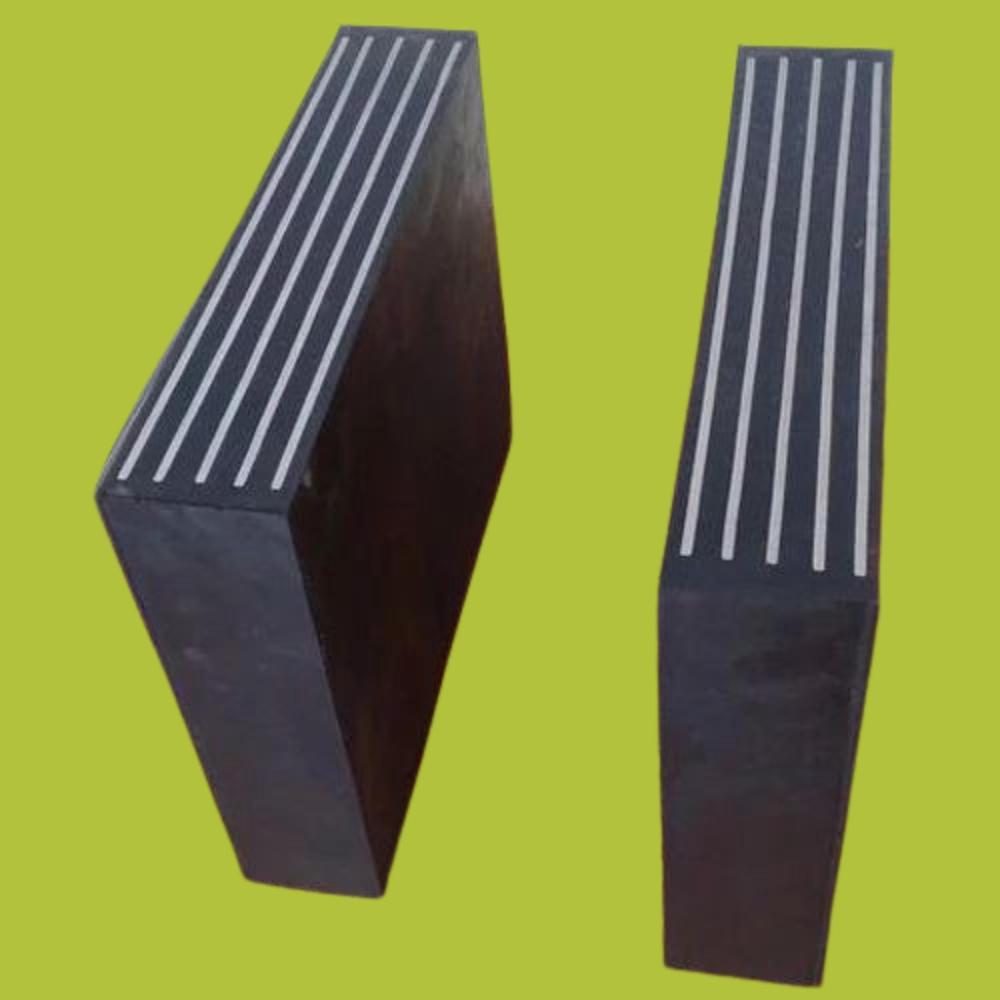

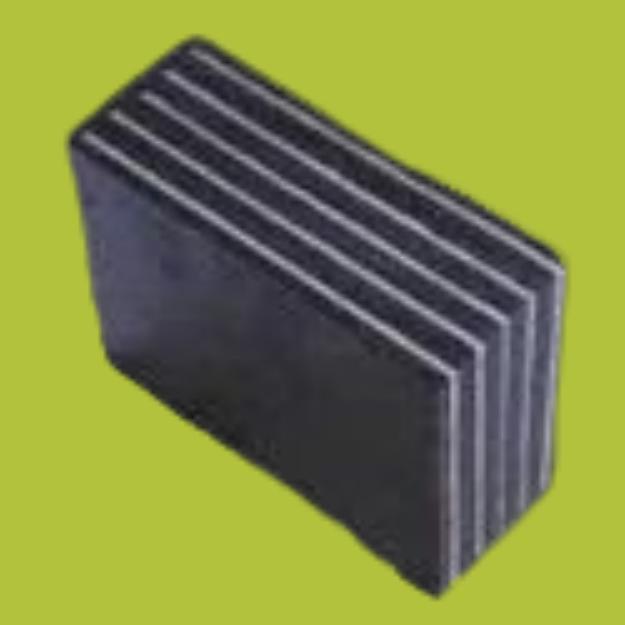

elastomeric bearings

Price 6000.0 INR/ Number

elastomeric bearings Specification

- Thickness

- 12 mm to 300 mm (customizable)

- Lubrication Type

- Maintenance Free

- Precision Rating

- Standard Structural Grade

- Bearing Type

- Elastomeric Bearing

- Material

- High grade Natural Rubber with Steel Lamination

- Structure

- Rectangular Layered

- Seals Type

- No Seals (solid piece)

- Number Of Rows

- Single

- Bore Size

- Custom as per specification

- Outside Diameter

- Custom as per design

- Load Capacity

- High (suitable for bridge and structural loads)

- Working Temperature Range

- -40°C to +70°C

- Compressive Strength

- Above 10 MPa

- Surface Finish

- Smooth

- Shape

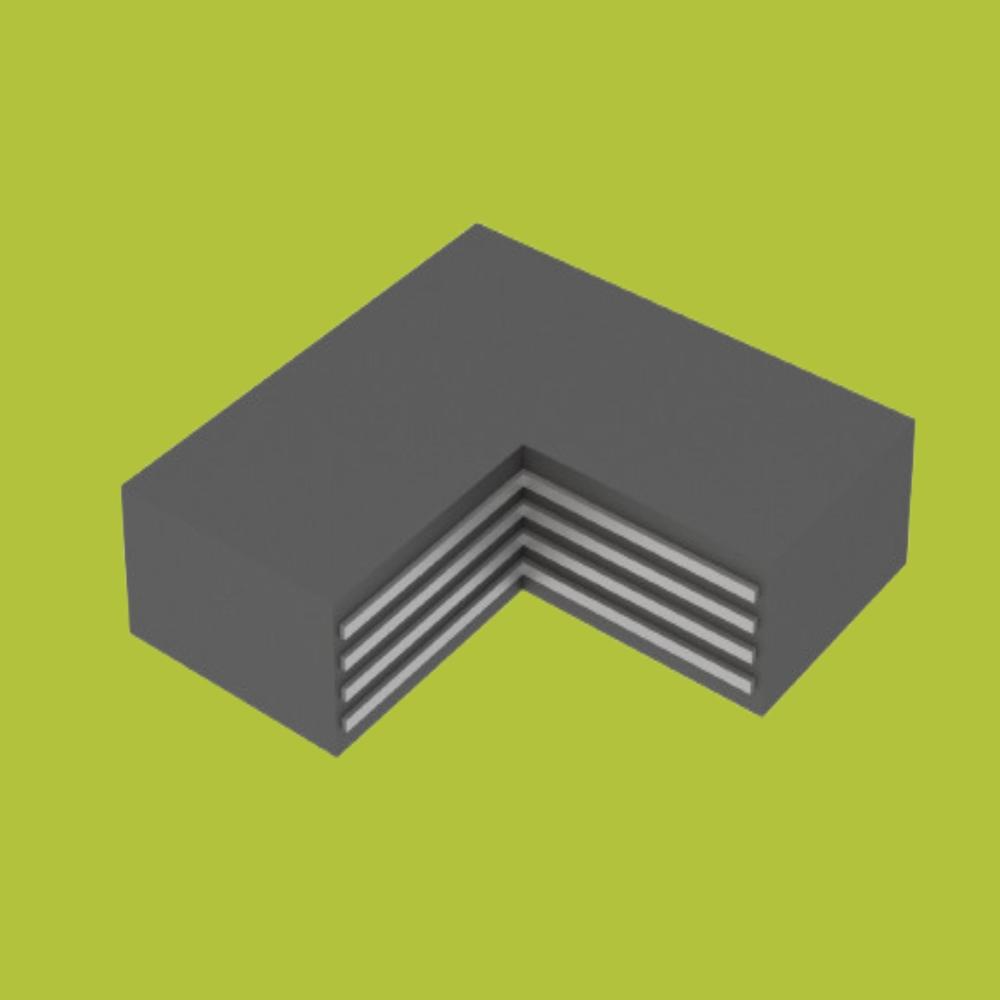

- Rectangular or Circular

- Manufacturing Process

- Vulcanized under controlled conditions

- Hardness

- 60+/-5 Shore A

- Color

- Black

- Service Life

- Over 25 years under recommended conditions

- Shear Modulus

- 0.90 ± 0.15 MPa

- Application

- Bridges, Flyovers, Precast and RCC Structures

About elastomeric bearings

Elastomeric Bearings are essential components used in structural engineering, particularly in the design of bridges, buildings, and other infrastructure where flexibility, vibration damping, and load distribution are crucial. These bearings are designed to accommodate movements and forces between structural elements while providing support and stability.

Elastomeric Bearings

Product Description:

Elastomeric Bearings are made from a blend of rubber (usually natural rubber or synthetic elastomers) and reinforced with steel plates or other materials for strength. These bearings are used to transfer loads, allow rotations, and accommodate movements between two connected structures. They are ideal for applications like bridge joints, expansion joints, and seismic isolation.

Key Features:

-

High Load-Bearing Capacity: Elastomeric bearings are designed to withstand heavy loads and dynamic forces without compromising performance.

-

Flexibility and Movement Accommodation: They allow for horizontal and vertical movements, which is important for structures subject to expansion, contraction, or seismic events.

-

Durable and Long-Lasting: Made from high-quality elastomers and reinforced with steel or other materials, these bearings are resistant to wear, aging, and environmental damage.

-

Corrosion Resistant: With steel reinforcement and rubber materials, elastomeric bearings are resistant to rust and corrosion, making them ideal for long-term use in various environments, including marine or coastal areas.

-

Cost-Effective: Compared to other bearing types, elastomeric bearings are often more affordable and easier to install.

Types of Elastomeric Bearings:

-

Plain Elastomeric Bearings:

-

Made of layers of elastomeric material (typically rubber) and steel plates.

-

Used for: Load distribution and accommodating small rotations and movements.

-

-

Elastomeric Bearings with Steel Reinforcement:

-

Composed of elastomeric material with embedded steel reinforcement.

-

Used for: Larger loads, enhanced movement capabilities, and seismic isolation.

-

-

High-Performance Elastomeric Bearings:

-

Enhanced with specialized rubber compounds for higher strength and durability.

-

Used for: Extreme conditions, heavy loads, and seismic zones.

-

Applications:

-

Bridge Engineering: Used extensively in bridges to accommodate movement due to thermal expansion, traffic loads, and seismic activity.

-

Buildings and Structures: Installed in the foundation to manage settlement, rotations, and seismic forces.

-

Seismic Isolation: Used in seismic isolation systems to decouple buildings from ground movements during earthquakes.

-

Infrastructure: Used in roadways, tunnels, viaducts, and other critical infrastructure for load distribution and stress relief.

Benefits:

-

High-Performance Seismic Isolation: Elastomeric bearings can help absorb and dissipate seismic forces, enhancing the stability of buildings and bridges during earthquakes.

-

Shock Absorption and Vibration Damping: These bearings are particularly effective at reducing vibrations from traffic, machinery, or other dynamic loads.

-

Compact Design: Elastomeric bearings can be designed to be compact and lightweight, making them easy to transport and install.

-

Flexibility in Design: These bearings are customizable for different applications, ensuring optimal performance.

-

Longevity: With the ability to endure harsh environmental conditions, elastomeric bearings often last longer than other bearing types.

Customization Options:

-

Size & Shape: Elastomeric bearings come in various sizes and thicknesses, and can be tailored to fit the specific design and load requirements of your project.

-

Reinforcement Type: Bearings can be customized with stainless steel or carbon steel reinforcement for additional strength.

-

Rubber Composition: Different rubber types can be used depending on the desired properties (e.g., higher resistance to wear, oil, or extreme temperatures).

Typical Specifications:

| Specification | Details |

|---|---|

| Material | Natural or synthetic rubber, steel reinforcement |

| Dimensions | Customizable to meet project requirements |

| Load Capacity | Can handle loads from a few tons to several thousand tons |

| Hardness | Varies depending on the rubber grade (typically between 50-80 Shore A) |

| Service Temperature | Typically between -20C to +70C, but special grades can withstand more extreme temperatures |

| Design Lifespan | Typically designed for 25-50 years depending on environmental conditions |

| Movement Accommodation | Can accommodate both horizontal and vertical movements |

Installation & Maintenance:

-

Easy to Install: Elastomeric bearings can be installed with minimal preparation, often involving placing the bearings between structural elements and securing them.

-

Minimal Maintenance: These bearings require very little maintenance, as they are designed for long-term durability. Regular inspections to check for wear or degradation are recommended.

Advantages of Elastomeric Bearings:

-

Efficient Load Transfer: Distributes weight evenly across the structure.

-

Reduced Maintenance Costs: Once installed, elastomeric bearings require little to no ongoing maintenance.

-

Enhanced Structural Flexibility: Accommodates shifts and vibrations from environmental or traffic-related movements.

-

Cost-Effective: Compared to other types of bearings (like pot bearings), elastomeric bearings are often more economical.

Would you like:

-

A datasheet or installation guide for elastomeric bearings?

-

Help sourcing suppliers or manufacturers for elastomeric bearings?

-

Assistance with design recommendations or calculating load requirements for your project?

Let me know how I can assist you further!

Precision Design for Structural Demands

Our elastomeric bearings are crafted with robust natural rubber and embedded steel laminations to withstand demanding structural applications. The product is engineered for compressive and shear strength, ensuring superior durability and safety even under high bridge or flyover loads. Their customizable shapes and sizes guarantee a perfect fit for every project requirement.

Exceptional Durability and Maintenance-Free Operation

With a service life exceeding 25 years under prescribed conditions, these bearings require no regular lubrication or maintenance. Their vulcanized construction and smooth surface finish resist weather extremes and environmental stresses, supporting consistent performance throughout their lifetime.

Custom Solutions for Infrastructure Projects

Whether you need single row, rectangular, or circular designs, our elastomeric bearings are tailored to your specifications. Dealers, manufacturers, and suppliers across India can provide you with configurations suited for a wide range of bridge and RCC structures, ensuring seamless integration into new or existing projects.

FAQ's of elastomeric bearings:

Q: How are elastomeric bearings installed in bridges or flyovers?

A: Elastomeric bearings are positioned between the substructure and superstructure of bridges or flyovers. Installation typically involves placing the bearing on a prepared surface, ensuring it aligns accurately to allow for controlled movement and load distribution. Custom bore size and outside diameter are specified for each project to ensure optimal fit and function.Q: What benefits do these elastomeric bearings offer for structural applications?

A: These bearings provide effective absorption of shocks, accommodate structural movements, and minimize vibration transmission. Their maintenance-free operation, high load capacity, and long service life enhance safety and reduce lifecycle costs, making them ideal for large infrastructure projects.Q: When should elastomeric bearings be replaced or checked?

A: While designed for a service life exceeding 25 years, bearings should be periodically inspected during routine bridge or structure maintenance, especially after extreme weather events or heavy loading, to assess for any signs of wear or unusual deformation.Q: Where can I procure elastomeric bearings in India?

A: These bearings are available through various channels including dealers, fabricators, manufacturers, producers, retailers, suppliers, traders, and wholesalers across India. Customization and technical support are also offered by most suppliers to meet specific project needs.Q: What is the manufacturing process for these bearings?

A: Each bearing is manufactured by vulcanizing high-grade natural rubber under controlled conditions and integrating steel laminations to create a solid, durable composite. This process ensures uniformity in hardness, surface finish, and structural integrity.Q: How does the shape or thickness affect the performance of elastomeric bearings?

A: The shape (rectangular or circular) and thickness (12 mm to 300 mm, customizable) are tailored based on structural design requirements and load specifications. These parameters directly influence the bearing's ability to accommodate movements, transfer loads, and adapt to different bridge or building geometries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elastomeric Bridge Bearing Category

Heavy Duty Elastomeric Bridge Bearing

Price 3265 INR / Cubic Centimeter

Minimum Order Quantity : 100 Cubic Centimeters

Lubrication Type : Other

Material : Rubber

Bearing Type : Other

Number Of Rows : Other

Elastomeric Bridge Bearing

Price 0.36 INR / Piece

Minimum Order Quantity : 100000 Pieces

Lubrication Type : Other

Material : Carbon Steel

Bearing Type : Other

Number Of Rows : Single Row

P Series Pad

Price 250.0 INR / Piece

Minimum Order Quantity : 1 Piece

Lubrication Type : Other, Grease / Oil Lubrication

Material : Other, Sintered Bronze / Steel / Customized

Bearing Type : Other, P Series Pad

Number Of Rows : Single Row

Mounting with Stud

Price 370.0 INR / Piece

Minimum Order Quantity : 1 Piece

Lubrication Type : Other, Prelubricated (Grease)

Material : Other, Chrome Steel (SUJ2)

Bearing Type : Other, Stud Type Track Roller

Number Of Rows : Single Row

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS