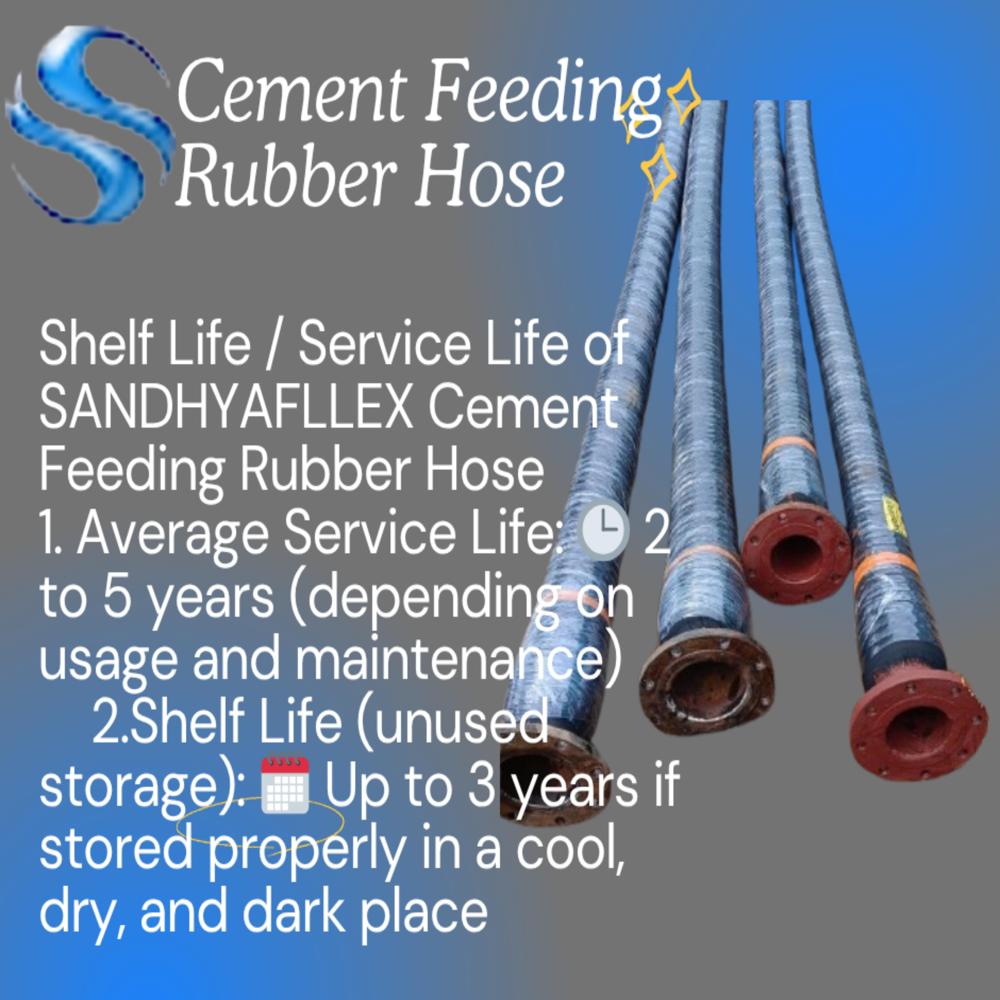

Cement Feeding Rubber Hose with Fixed Flange

Price 2100.0 INR/ Meter

About Cement Feeding Rubber Hose with Fixed Flange

Here's a detailed overview for a Cement Feeding Rubber Hose with Fixed Flange, commonly used in cement plants, bulk material handling, and silo feeding systems.

Cement Feeding Rubber Hose with Fixed Flange

**Product Description:

A heavy-duty, abrasion-resistant rubber hose** designed for pneumatic transfer of dry cement and other powdery bulk materials. The fixed flange allows secure, bolt-on connections to silos, pumps, or pipelines.

Applications:

-

Cement bulker unloading to silos

-

Pneumatic conveying systems

-

RMC (Ready Mix Concrete) plants

-

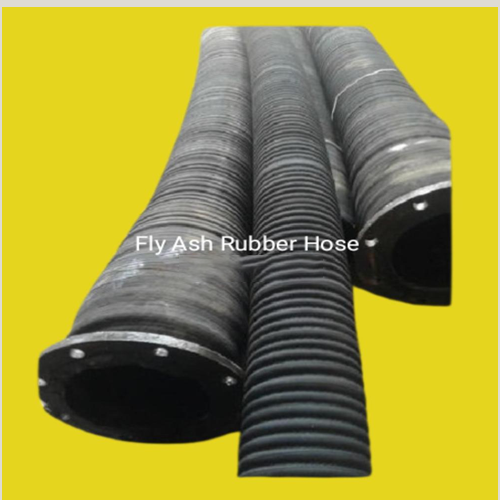

Fly ash & lime feeding systems

-

Bulk transport trailers

Construction:

| Component | Material / Details |

|---|---|

| Inner Tube | Highly abrasion-resistant rubber (NR, SBR) |

| Reinforcement | Synthetic fabric and/or steel wire for strength and pressure |

| Cover | Weather, abrasion, and ozone-resistant rubber |

| End Connection | Fixed MS or SS flange, drilled to ANSI/DIN standard |

Typical Technical Specifications:

| Parameter | Value/Range |

|---|---|

| Inner Diameter (ID) | 2" to 6" (50 mm to 150 mm) |

| Length | Standard 36 meters (custom on request) |

| Working Pressure | 10 to 20 bar |

| Burst Pressure | Up to 60 bar |

| Temperature Range | -20C to +80C |

| Flange Type | Fixed flange MS/SS, ANSI/DIN standard |

| Bend Radius | As low as 10x the hose ID |

| End Options | Fixed flange both ends / one end fixed, one end rotating |

Key Features:

-

Abrasion resistant inner lining for dry cement

-

Flexible and kink-resistant

-

Corrosion-resistant flanged connections

-

Suitable for high-speed pneumatic cement transfer

-

Long service life in rugged field conditions

Optional Customizations:

-

Inner lining for fly ash or lime

-

Rotating flange on one end

-

Food-grade or chemical-grade rubber (for other materials)

-

Color-coded outer cover

Would you like:

-

A sample technical datasheet or BOQ format?

-

Help finding suppliers or manufacturers?

-

Help determining hose size/length based on your plant layout?

Let me know your use case and Ill tailor the info!

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free