concret end hose

Price 25000.00 INR/ Meter

concret end hose Specification

- Medium

- High Water Content Liquid

- Hardness

- Medium

- Shape

- Round

- Usage

- Industrial

- Material

- Rubber

- Size

- Standard

- Color

- Black

- Warranty

- Yes

About concret end hose

A concrete end hose is a specialized hose used in the concrete pumping industry. It's designed to handle the transfer of freshly mixed concrete to a specific location, often at the final stage of the concrete pouring process. Concrete end hoses are typically used in conjunction with concrete pumps or mixers to deliver concrete precisely where it is needed, such as in construction projects involving foundations, floors, walls, or other concrete structures.

Key Features of a Concrete End Hose:

-

High Abrasion Resistance:

-

Concrete is highly abrasive, which means that a concrete end hose must be made of durable materials that can withstand the friction and wear caused by the flow of the mixture. These hoses are often reinforced with high-strength materials like steel cables or textile fibers to ensure they dont get damaged quickly.

-

-

Flexibility:

-

Concrete end hoses are designed to be flexible, making them easy to maneuver in tight or complex construction areas. This allows workers to direct the hose to hard-to-reach places, such as high-rise buildings, narrow areas, or confined spaces.

-

-

Pressure Resistance:

-

These hoses are built to handle the high-pressure conditions that exist during the pumping process. They can withstand the pressure exerted by the concrete pump, which can be substantial, especially when pumping large volumes of concrete over long distances.

-

-

Smooth Interior Lining:

-

The inner lining of the concrete end hose is often smooth to minimize friction, which helps the concrete flow more easily and reduces the chances of clogging or blockages. The smooth surface also reduces wear inside the hose.

-

-

Durability and Strength:

-

Given that concrete is a dense and heavy material, concrete end hoses are made with robust materials to ensure they can handle the weight of the concrete, any impacts from rough surfaces, and the wear that comes from continuous use in the construction process.

-

-

Heavy-Duty Couplings:

-

Concrete end hoses come equipped with heavy-duty couplings that ensure a secure connection between the hose and the concrete pump or between multiple hoses, preventing leaks or separations under pressure.

-

Common Applications of a Concrete End Hose:

-

Construction Sites:

-

The primary use for concrete end hoses is on construction sites where concrete needs to be pumped into place. They are used to pour concrete into foundations, building slabs, columns, and walls.

-

-

High-Rise Building Projects:

-

For tall buildings or high-rise construction, concrete end hoses are used to deliver concrete at elevated levels, sometimes extending from a pump at ground level or from a concrete boom pump.

-

-

Bridges and Roads:

-

Concrete end hoses are also used in infrastructure projects like road construction or bridge building, where concrete needs to be poured in specific sections or forms.

-

-

Residential and Commercial Construction:

-

In smaller-scale construction projects, concrete end hoses are used for pouring floors, driveways, sidewalks, and other smaller concrete structures.

-

Construction and Composition:

-

Rubber or Rubber-Lined Construction: The hose body is typically made from high-quality rubber, which is reinforced to provide the strength needed to withstand pressure and abrasion. This rubber is often designed to be flexible and durable to cope with the wear and tear of pumping concrete.

-

Reinforcement: These hoses often have an internal reinforcement layer made from steel wire or synthetic textiles to provide strength and prevent kinking under pressure. This reinforcement is crucial to maintaining the structural integrity of the hose during high-pressure concrete pumping.

-

End Fittings: The hose typically features high-quality metal couplings or end fittings designed to securely connect the hose to the pump or other hoses. These fittings are designed to withstand high pressure and prevent leaks during the pumping process.

Sizes and Specifications:

-

Concrete end hoses come in a variety of sizes, typically ranging from 2 inches to 6 inches in diameter, depending on the specific requirements of the job.

-

The length of the hose can vary, with hoses often available in 10-foot to 40-foot sections that can be coupled together for longer runs if needed.

Advantages of Using a Concrete End Hose:

-

Efficient Concrete Delivery: Concrete end hoses allow for precise delivery of concrete, especially in hard-to-reach areas or when a pump cannot directly reach the site of the pour.

-

Flexibility and Maneuverability: Their flexibility makes them highly adaptable to various construction needs, whether its a large-scale pour or a small, tight-area job.

-

Durability: Built to handle the high wear and tear that comes from abrasive materials, concrete end hoses are strong enough to stand up to the demands of continuous concrete pumping.

-

Ease of Use: The hoses are designed to be easy to attach and detach from pumps and other hoses, making them a practical choice for construction teams working under tight deadlines.

Maintenance and Care:

-

Regular cleaning and maintenance are necessary to avoid blockages from hardened concrete. It's recommended to flush out the hose with water after each use.

-

Inspecting for any cracks or damage in the hose is crucial to ensuring safety and preventing leaks or hose failure during concrete pumping.

Would you like more specific details on the different types of concrete hoses, or do you need help with selecting the right hose for a particular concrete application? Let me know!

Reliable Performance in Industrial Settings

The concret end hose is engineered to deliver optimal performance in demanding industrial conditions, particularly for conveying high water content liquids. Its medium hardness rubber construction ensures a perfect balance of strength and flexibility, reducing the risk of kinking and wear in high-pressure systems.

Versatility and Wide Availability

This hose's standard sizing and compatibility with industrial systems make it a versatile choice for various sectors across India. Customers can easily source it from authorized dealers, fabricators, and an extensive network of suppliers, ensuring prompt and reliable availability for every industrial need.

FAQ's of concret end hose:

Q: How should the concret end hose be installed for optimal durability?

A: To ensure optimal durability, the hose should be installed without excessive twisting or bending. Secure connections with proper clamps, and regularly check for signs of wear to prolong the product's lifespan.Q: What industrial applications is this hose suitable for?

A: This concret end hose is ideal for transferring high water content liquids in construction, mining, chemical plants, and other heavy-duty industrial settings due to its resilient rubber construction.Q: Where can I purchase this hose in India?

A: You can purchase this hose from various dealers, manufacturers, retailers, suppliers, and wholesalers throughout India. Contact local distributors or search online for authorized sellers in your area.Q: What is the recommended process for cleaning and maintaining this hose?

A: After each use, flush the hose thoroughly with clean water to remove residues. Store it in a cool, dry location away from direct sunlight and chemicals. Inspect regularly for signs of deterioration.Q: When should the hose be replaced?

A: Replace the hose if you notice visible cracks, leaks, severe stiffness, or loss of flexibility, as these signs indicate wear that may compromise its performance and safety.Q: What are the key benefits of using this rubber hose with medium hardness?

A: The medium hardness offers a solid combination of flexibility and strength, helping to prevent breaks and kinks during use while maintaining stable flow rates in high-pressure applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Rubber Hoses Category

Industrial Water Suction and Discharge Rubber Hose

Price 4000.0 INR / Meter

Minimum Order Quantity : 1 Piece

Shape : Cylinderical

Cover : RUBBER

Material : Rubber

Hardness : Varies

Fly Ash Rubber Hose

Price 1500 INR / Meter

Minimum Order Quantity : 100 Meters

Shape : Round

Cover : Rubber

Material : Rubber

Hardness : 60 to 65 Shore A

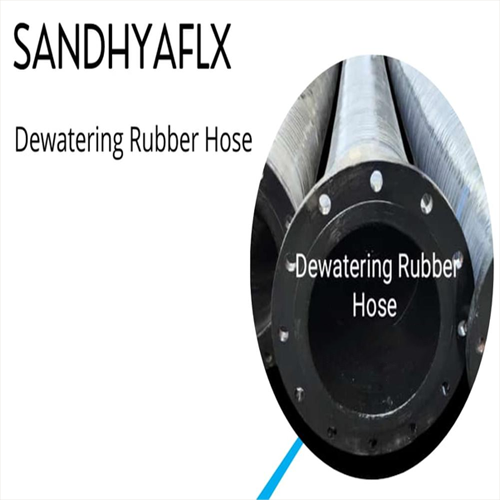

DEWATERING RUBBER HOSE 1INCH

Price 650.0 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : Round

Cover : Abrasion & Weather Resistant Rubber

Material : Other, Natural/Synthetic Rubber

Hardness : 605 Shore A

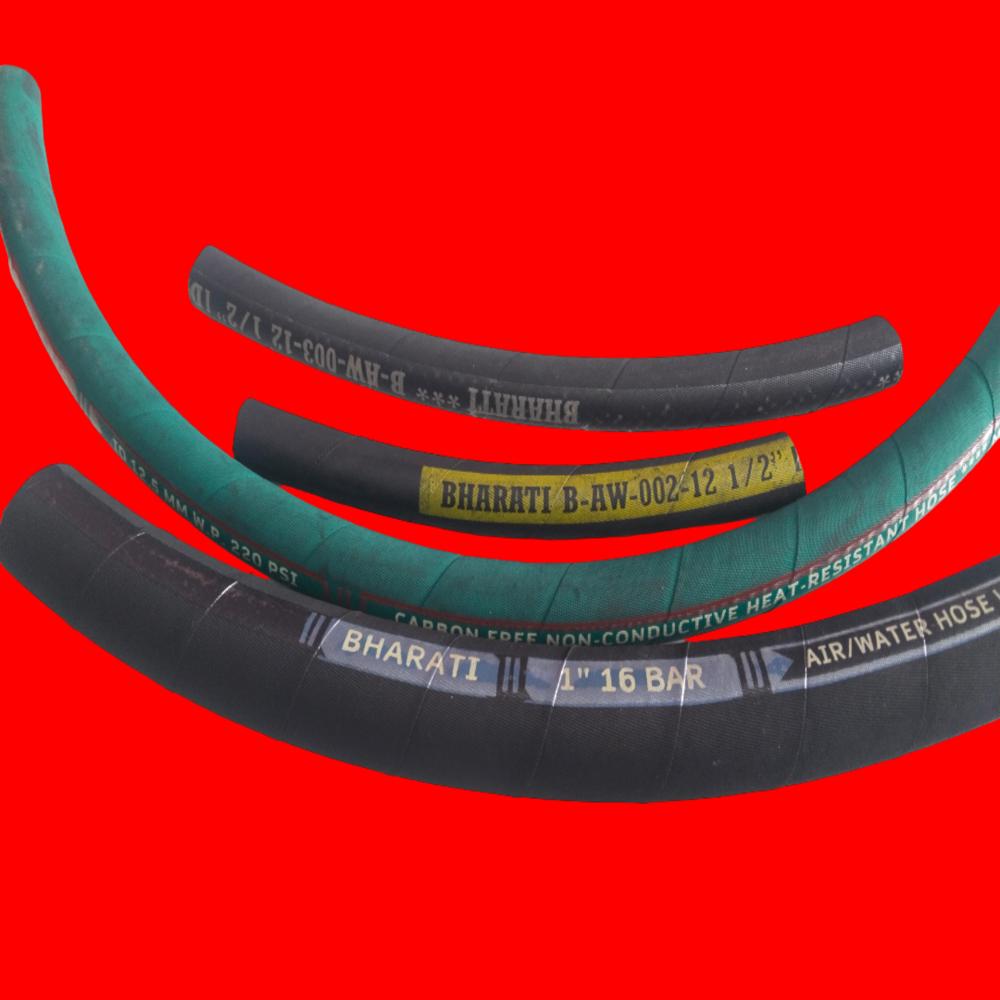

Textile Braided Pipe

Price 350.0 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : Round

Cover : Smooth, Resistant to Oil and Weather

Material : Other, PVC (Polyvinyl Chloride)

Hardness : 6575 Shore A

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free