Squire Rubber Beading

Price 400.00 INR/ Meter

Squire Rubber Beading Specification

- Color

- Black

- Ash %

- Yes

- Material

- Neoprene Rubber

- Size

- Standerd

- Feature

- Weather Resistance

- Hardness

- 20 to 80 Shore A

- Thickness

- 10 Millimeter (mm)

- Product Type

- Rubber Beading

- Usage & Applications

- Industrial

Squire Rubber Beading Trade Information

- Minimum Order Quantity

- 100 Meter

- FOB Port

- mumbai

- Supply Ability

- 2000 Per Day

- Delivery Time

- 4 Days

- Packaging Details

- Packing in Coil

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001.2015

About Squire Rubber Beading

Rubber strips are versatile materials with a wide range of uses and applications across various industries. Here are some common uses and applications of rubber strips:

1. Sealing Applications Rubber strips are often used for sealing purposes due to their flexibility and ability to conform to irregular surfaces. They can be employed in doors, windows, automotive weatherstripping, and other sealing applications to prevent air, water, dust, and noise infiltration.

2. Weatherproofing Rubber strips are utilized for weatherproofing outdoor structures such as sheds, garages, and barns. They provide a barrier against rain, snow, and drafts, helping to maintain interior comfort and protect stored items from moisture damage.

3. Vibration Dampening Rubber strips are effective in reducing vibrations and noise transmission. They can be installed between mechanical components or structural elements to dampen vibrations and absorb shocks, thus minimizing noise and prolonging equipment lifespan.

4. Gasketing Rubber strips are commonly used as gaskets in machinery, engines, pumps, and piping systems to create a tight seal between mating surfaces and prevent fluid or gas leakage. They offer resistance to various chemicals, oils, and temperatures, making them suitable for diverse gasketing applications.

5. Cushioning and Padding Rubber strips serve as cushioning and padding materials in furniture, packaging, sports equipment, and automotive interiors. They provide comfort, shock absorption, and protection against impacts, enhancing user experience and product durability.

6. Expansion Joints Rubber strips are utilized in expansion joint assemblies to accommodate movement and thermal expansion in structures such as bridges, buildings, and pavements. They help to maintain structural integrity, prevent cracking, and extend the service life of construction projects.

7. Electrical Insulation Rubber strips with insulating properties are employed in electrical and electronic applications to provide insulation, moisture resistance, and protection against electrical hazards. They are used in wiring harnesses, electrical enclosures, and cable management systems.

8. Decorative Trim Rubber strips can be used as decorative trim or edging on furniture, countertops, appliances, and automotive interiors. They enhance aesthetics, cover rough edges, and provide a finished appearance to the surfaces.

Overall, rubber strips offer versatility, durability, and reliability in a wide range of industrial, commercial, and residential applications, making them indispensable components in various products and systems.

Versatile Industrial Application

Designed to meet the demanding needs of industrial environments, Squire Rubber Beading offers flexibility and resilience required for sealing, gasketing, and vibration damping. Its neoprene composition delivers an optimal balance of hardness and elasticity, making it a preferred solution in automotive, construction, and machinery sectors.

Weather Resistance You Can Trust

Engineered with superior weather-resistant properties, this rubber beading withstands rain, UV exposure, and fluctuating temperatures. Whether used indoors or outdoors, its performance remains consistent, helping to extend the lifespan of equipment and reduce the frequency of maintenance.

FAQ's of Squire Rubber Beading:

Q: How is Squire Rubber Beading typically installed in industrial applications?

A: Squire Rubber Beading can be easily installed by pressing or inserting it into designated grooves or channels on machinery, doors, or windows. Adhesives or mechanical fasteners may enhance stability, depending on the application's requirements.Q: What are the primary benefits of using neoprene rubber in Squire Rubber Beading?

A: Neoprene rubber provides exceptional durability, flexibility, and resistance to weather, oil, and chemicals. These qualities make Squire Rubber Beading highly suitable for protecting against moisture, dust, and environmental deterioration in industrial settings.Q: When should I replace the rubber beading in my industrial equipment?

A: You should replace the rubber beading if you notice visible signs of wear, cracking, loss of elasticity, or significant deformation. Regular inspections are advisable to ensure continuous protection and performance.Q: Where can I purchase Squire Rubber Beading in India?

A: Squire Rubber Beading is available nationwide through dealers, fabricators, manufacturers, producers, suppliers, traders, wholesalers, and retailers specializing in industrial rubber components. Distribution covers both urban and industrially concentrated regions.Q: What is the process for customizing the beading size or hardness for specific requirements?

A: For specialized needs, customers can contact the manufacturer or supplier directly to request custom hardness, size, or thickness. The production process is flexible, allowing adjustments according to detailed industrial specifications.Q: How does the ash content benefit the rubber beading's performance?

A: The ash content in Squire Rubber Beading enhances structural stability and resistance to abrasive forces, resulting in improved durability and longevity, particularly under challenging environmental or operational conditions.Q: What makes Squire Rubber Beading suitable for weather-exposed environments?

A: The product's neoprene material is inherently weather-resistant, providing robust defense against UV rays, rain, and temperature shifts. This property ensures reliable sealing and protection for outdoor and indoor industrial uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

Sponge Rubber Profiles

Price 80 INR / Meter

Minimum Order Quantity : 100

Color : Black, White, Gray (other colors available on request)

Natural Rubber : Available upon request

Size : Customizable as per requirement

Material : EPDM, Silicone, Neoprene, Nitrile, NR available

Conductive Rubber Sheet

Price 350 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Color : Black

Natural Rubber : Synthetic Blend / Natural Rubber available

Size : Customizable as per requirement

Material : EPDM, Silicon, or Natural Rubber with conductive fillers

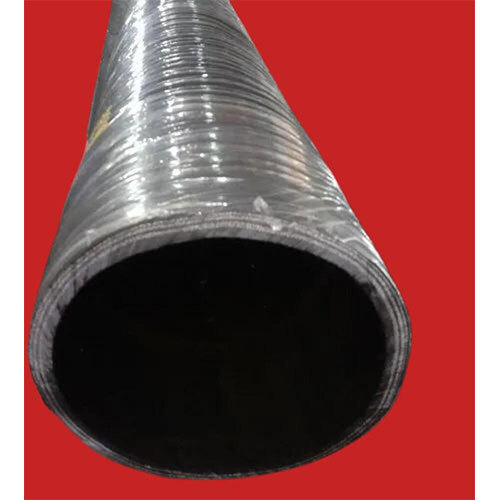

Slurry Rubber Hose

Price 4300.0 INR

Minimum Order Quantity : 1 Meter

Color : Black

Natural Rubber : High grade natural rubber compounded

Size : 4 inch to 20 inch (Inner Diameter)

Material : Natural Rubber, Synthetic Rubber (NR, SBR, or blend), Reinforced with textile and steel wire

Slurry Rubber Hose

Price 3500.0 INR / Meter

Minimum Order Quantity : 6

Color : Black

Natural Rubber : Natural

Size : Standard

Material : Rubber

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS