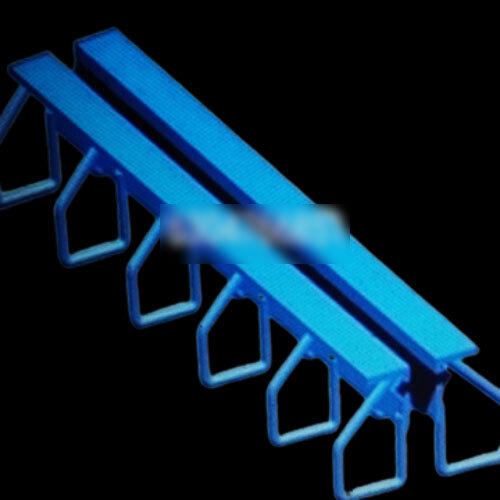

Slab Seal Expansion Joint

Price 8500.0 INR/ Piece

Slab Seal Expansion Joint Specification

- Max. Temperature

- 27 to 50 Deg C Celsius (oC)

- Usage

- Bridge Construction

- Technique

- Casting

- Size

- 50x320x1000mm

- Product Type

- Slab Seal Expansion Joint

- Color

- Black

Slab Seal Expansion Joint Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 2000 Pieces Per Day

- Delivery Time

- 4 Days

About Slab Seal Expansion Joint

A Slab Seal Expansion Joint is a specialized type of expansion joint used in concrete structures to accommodate the movement caused by thermal expansion, contraction, and other forces like traffic load or seismic activity. These joints are particularly used in slabs (such as road slabs, bridge decks, floors, etc.) to maintain the structural integrity and prevent cracks or damage due to movement.

Key Features of Slab Seal Expansion Joints:

-

Function:

-

Accommodate Movement: The primary function of a slab seal expansion joint is to allow for the expansion and contraction of the concrete structure without causing damage. It provides a gap or seal that allows the concrete to move while preventing water, debris, and contaminants from entering the joint.

-

Prevent Cracking: Without an expansion joint, the movement of the concrete could cause cracking, deformation, and deterioration, especially in large concrete slabs.

-

Waterproofing: Slab seal joints help in maintaining a waterproof seal, preventing the entry of moisture, which could lead to rusting of reinforcement bars, corrosion, or freeze-thaw damage.

-

-

Material:

-

PVC (Polyvinyl Chloride): Often used in the seal or the strip material, PVC is durable, flexible, and resistant to environmental factors such as UV radiation and weathering. It also provides excellent sealing properties.

-

Elastomeric Materials: Materials like EPDM (Ethylene Propylene Diene Monomer) or neoprene are commonly used in slab seal expansion joints because of their flexibility, longevity, and resistance to chemicals and temperature extremes.

-

Steel: In some cases, the expansion joint may include steel reinforcement to enhance durability and strength, particularly in heavy-duty applications like road or bridge decks.

-

-

Design:

-

Flexible Sealing System: Slab seal joints usually consist of a flexible seal that fits into a groove or channel in the concrete slab. This flexible seal can expand and contract as needed while ensuring the joint remains sealed.

-

Profile: The joint system often includes a V-shaped or U-shaped profile that helps to better handle movement while ensuring the integrity of the seal.

-

Rubber or Silicone: Rubber seals or silicone-based materials can also be used in some cases, offering enhanced flexibility and weather resistance.

-

-

Types of Slab Seal Expansion Joints:

-

Compression Seal Joints: These are designed to compress and expand with the movement of the concrete slab, offering a tight, waterproof seal.

-

Strip Seal Joints: A pre-formed seal (often made of elastomeric material) that is placed into a slot in the concrete, commonly used in bridge decks, roadways, and other structures that experience continuous movement.

-

Polymer-Based Joints: These can offer enhanced chemical resistance and high tensile strength, making them suitable for areas with high traffic and extreme weather conditions.

-

-

Applications:

-

Bridges: For expansion joints in bridge decks that handle large amounts of traffic and temperature-induced movement.

-

Roadways and Highways: On road surfaces and highways, where thermal expansion and contraction are frequent.

-

Parking Structures: Used in concrete floors and slabs in multi-story parking garages to accommodate movement from load and temperature changes.

-

Floor Slabs in Buildings: In large commercial or industrial buildings, slab seal expansion joints prevent cracking in floors caused by shifting or temperature fluctuations.

-

-

Advantages:

-

Prevents Damage: Helps to prevent cracking, buckling, and structural damage due to concrete movement.

-

Maintains Structural Integrity: Accommodates both horizontal and vertical movement while maintaining the seal.

-

Waterproofing: It prevents the ingress of water and other damaging elements that could compromise the concrete.

-

Durable and Low Maintenance: High-quality slab seal expansion joints are durable and require little to no maintenance once installed.

-

-

Installation:

-

Preparation: Proper surface preparation of the slab is essential. This involves cleaning and ensuring that the groove or slot for the expansion joint is appropriately sized and free of debris.

-

Sealing: The expansion joint material (often a flexible rubber or PVC strip) is installed into the prepared groove and is secured using appropriate fasteners or adhesives.

-

Sealing the Edges: The edges of the joint may be sealed with a sealant or mastic to prevent water infiltration and enhance the joint's durability.

-

Benefits:

-

Enhanced Safety: Prevents water from entering joints and causing corrosion or weakening the structure.

-

Adaptability: Can handle a range of movements from thermal expansion to seismic forces.

-

Cost-Effective: Reduces the need for costly repairs caused by water damage, cracking, or shifting.

Conclusion:

A Slab Seal Expansion Joint is crucial for maintaining the functionality and durability of concrete structures exposed to temperature changes, load movement, and environmental factors. Whether it is for roads, bridges, floors, or parking decks, the slab seal expansion joint provides a reliable and flexible solution to accommodate movement while protecting the structure from water and debris damage.

Let me know if you'd like more details on installation methods, specific product recommendations, or if you need help sourcing materials!

Engineered for Durability

Our Slab Seal Expansion Joint is meticulously crafted for bridge applications, ensuring optimal flexibility where movement due to traffic and temperature can cause stress. The cast design guarantees consistent quality and performance under rigorous conditions in the 27 to 50C temperature range.

Seamless Integration in Bridge Construction

Thanks to its standardized size (50x320x1000mm) and practical color, our joint seamlessly integrates with bridge decks. Its compatibility with casting techniques makes it easy to install, maximizing efficiency while minimizing downtime on site.

FAQ's of Slab Seal Expansion Joint:

Q: How is the Slab Seal Expansion Joint installed in bridge construction?

A: The joint is installed during the casting phase, positioned between concrete slabs to allow for thermal and structural movement. Professional alignment and securement techniques are used to ensure long-term performance.Q: What are the key benefits of using this expansion joint in bridges?

A: This joint helps absorb movement caused by temperature changes (from 27 to 50C), thereby preventing cracking and extending the lifespan of bridge structures. Its robust build also reduces maintenance frequency.Q: When should the Slab Seal Expansion Joint be considered during project planning?

A: It should be specified at the design stage and incorporated during construction casting, particularly in regions of India with significant temperature variations and high bridge load demands.Q: Where can I source this expansion joint in India?

A: The product is readily available through dealers, fabricators, manufacturers, producers, retailers, suppliers, traders, and wholesalers throughout India. You can source it directly or via local construction supply distributors.Q: What materials and manufacturing process are used for this expansion joint?

A: The joint is produced using a casting technique, resulting in a reliable black-colored product that withstands intense mechanical and thermal stress typical in bridges.Q: How is the 50x320x1000mm size advantageous for bridge applications?

A: This dimension is optimized to provide adequate movement accommodation and load support for standard bridge structures, ensuring stability without compromising the bridge deck's integrity.Q: What usage precautions should be taken during installation?

A: Ensure the joint is installed within the specified temperature range and with correct positioning. Employing experienced construction professionals will prevent misalignment and maximize the protective benefits.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bellow And Expansion Joint Category

Industrial Rubber Expansion Joint

Price 12000 INR / Unit

Minimum Order Quantity : 100 Units

Connecting Type : Others, Flanged

Material : Other

Surface Treatment : Other, Smooth Rubber Finish

Size : 25mm to 500mm

F Type Strip Seal Expansion Joint

Price 2800 INR / Meter

Minimum Order Quantity : 100 Meters

Connecting Type : Welding

Material : Iron

Surface Treatment : Painted

Size : Depth 80 mm

Strip Seal Expansion Joint

Price 3000 INR / Meter

Minimum Order Quantity : 100

Connecting Type : Welding

Material : Iron

Surface Treatment : Painted

Size : as per Drg

Bridge Strip Seal Expansion Joint

Price 3000 INR / Meter

Minimum Order Quantity : 100 Meters

Connecting Type : Welding

Material : Iron

Surface Treatment : Painted

Size : 80mm Height

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free