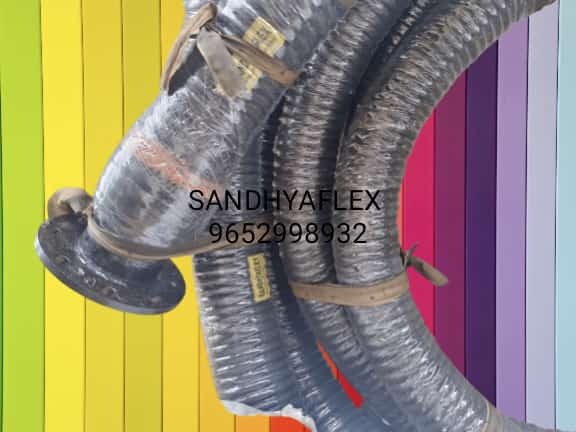

Rubber hose

Price 1125.0 INR/ Number

Rubber hose Specification

- Temperature Resistance

- -40C to +100C (standard), up to +120C for specific compounds

- Surface Finish

- Smooth/Matte

- Flame Resistance Level

- Available with flame retardant properties

- Material

- Natural Rubber/SBR/NBR/EPDM (as per specification)

- Rubber Type

- Natural, SBR, NBR, EPDM available

- Width

- Variable, customizable as per requirement

- Style

- Plain/Smooth and Corrugated

- Thickness

- 3 mm to 10 mm (custom available)

- Size

- 1/2 inch to 4 inch (custom sizes available)

- Components

- Inner tube, Reinforcement layer, Outer cover

- Part Type

- Flexible Hose Pipe

- Water Absorption

- < 2% (by weight)

- Tensile Strength

- 8 to 20 MPa (typical)

- Feature

- Flexible, Abrasion resistant, Weather resistant, Durable

- Usage & Applications

- Industrial fluid transfer, hydraulic and pneumatic systems, water and air delivery, chemical transport

- Product Type

- Rubber Hose

- Density

- 0.05 Gram per cubic centimeter(g/cm3)

- Color

- Black

- Weight

- Varies with size and length

- Tolerance

- 0.5 mm (standard)

- Natural Rubber

- Available as natural rubber or with synthetic blends

- Hardness

- 65-75 Shore A

- Diameter

- 13 mm to 100 mm

- Resistance level

- High resistance to chemicals, abrasion, ozone, and weathering

- Length

- up to 60 meters

- Thermal Conductivity

- Low thermal conductivity

- Burst Pressure

- Minimum 3 times working pressure

- Storage Recommendation

- Store in cool, dry, and shaded places, avoid direct sunlight

- Inner Tube Material

- Oil/mild chemical resistant synthetic rubber

- Outer Cover Material

- Weather and abrasion resistant rubber

- End Connections

- Plain, flanged, or with fittings as needed

- Marking/Identification

- Customized printing/embossing available

- Ozone Resistance

- Excellent, suitable for outdoor use

- Working Pressure

- 10 to 25 Bar (depends on size and type)

- Minimum Bend Radius

- 4x nominal diameter

- Standards Complied

- IS 444/IS 5384 or as per customer requirement

- Electrical Resistance

- Available with antistatic and conductive properties

- Reinforcement Type

- High tensile synthetic yarn or wire braid

About Rubber hose

Optimal Utility for Industrial and General Use

Our rubber hoses are engineered for versatile usage, addressing industrial fluid transfer, hydraulic and pneumatic systems, and water or chemical delivery. Application is effortless: simply connect through plain, flanged, or fitted ends as needed. The hose's composition-oil and mild chemical-resistant synthetic rubber with high-tensile reinforcement-offers flexibility and durability. Their range of sizes, styles, and custom features make them an excellent solution for demanding work environments.

Seamless Packaging, Delivery, and Logistics

Once a purchase order is confirmed, your rubber hose is securely packed for transit, ensuring product integrity. Handed over to reliable logistics partners at the designated FOB port, we guarantee prompt and safe delivery. Orders are typically processed and dispatched swiftly, with timelines clearly communicated. Careful packaging standards protect against damage during shipping, so your hoses arrive ready for immediate installation and use.

FAQ's of Rubber hose:

Q: How do I choose the right size and style of rubber hose for my application?

A: Selecting the correct hose involves considering your required diameter, pressure rating, and material compatibility. Our team can assist you in personalising the size, style (plain or corrugated), and end fittings to perfectly suit your needs.Q: What are the key benefits of using this flexible hose in industrial applications?

A: This hose offers prodigious resistance to chemicals, abrasion, and weather, ensuring longevity. Its flexibility, customisable length, and durability make it ideal for fluid transfer, hydraulics, and pneumatic uses.Q: When will my order be delivered after placing a purchase order?

A: Once your purchase order is processed, we promptly prepare and hand over the hoses to logistics partners. Delivery times depend on location and order specifics, but we provide clear timelines and continuous updates.Q: Where are the hoses manufactured and can I visit your facility in India?

A: Our rubber hoses are manufactured at certified facilities in India. We welcome dealer, retailer, and client visits-please contact us to arrange a tour or meeting.Q: How is the hose packaged and protected for shipping?

A: Each hose is securely packaged to prevent moisture, abrasion, and physical wear during transit. Careful handling and robust packing ensure the product reaches you in pristine condition, ready for use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

SANDHYAFLEX 10mm Gap Vibrating Screen Rubber Beading

Price 210.0 INR

Minimum Order Quantity : 1 Meter

Color : Black

Hardness : 60 5 Shore A

Material : Natural Rubber/Synthetic Rubber Blend

Size : 10mm gap

Cutless Rubber Bearing

Price 1250.0 INR

Minimum Order Quantity : 1

Color : Black

Hardness : 70 5 Shore A

Material : Rubber lined with metallic/bronze sleeve

Size : Standard and custom as per requirement

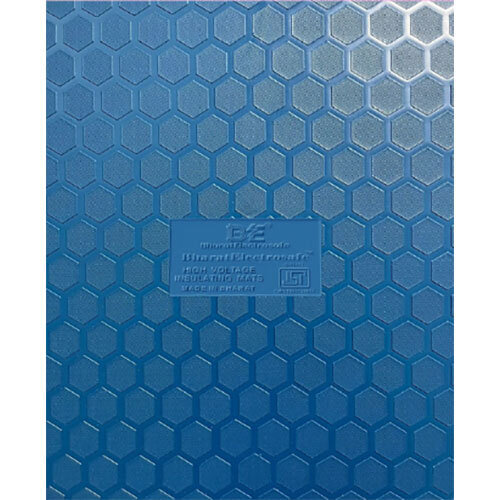

Electrical Insulating Rubber Sheet 2mm

Price 440.0 INR

Minimum Order Quantity : 1 Meter

Color : Black

Hardness : 65 5 Shore A

Material : Highquality natural rubber compound

Size : 1 meter x 10 meters roll

Swellable water bar

Price 180.00 INR / Meter

Minimum Order Quantity : 100

Color : Red

Hardness : Medium

Material : RUBBER

Size : 10 MM X 20 MM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS