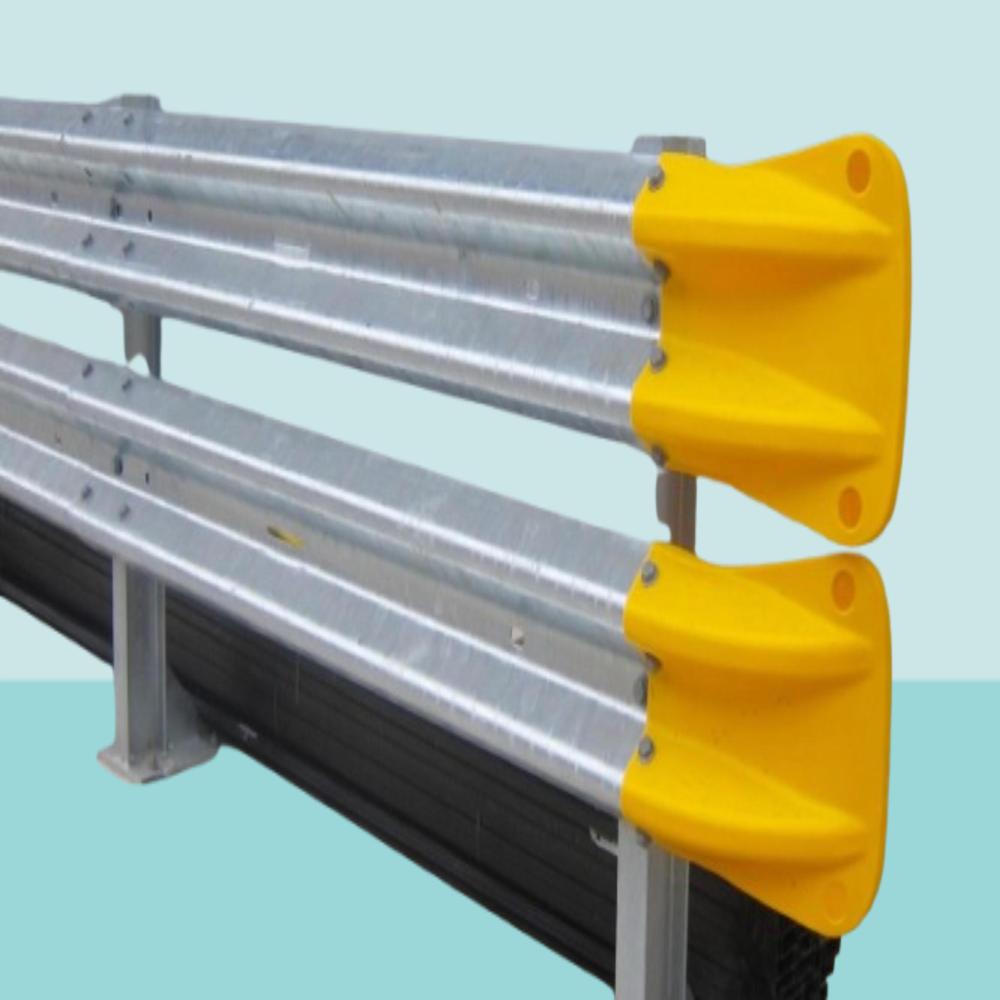

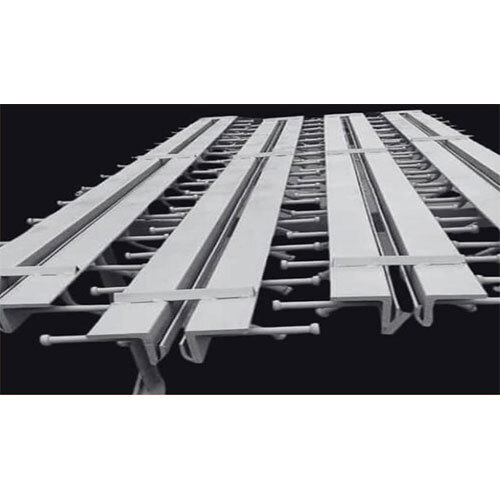

Metal Beam Crash Barrier

Price 2500.00 INR/ Meter

Metal Beam Crash Barrier Specification

- Display Type

- No

- Material

- Steel

- Color

- Silver

- Usage

- Industrial, Commercial, Road Safety

- Size

- Standard

- Weight

- 45 Kilograms (kg)

About Metal Beam Crash Barrier

A metal beam crash barrier is a type of road safety barrier used primarily along highways, roads, and bridges to protect vehicles and pedestrians from accidents and to prevent vehicles from veering off the road. These barriers are designed to absorb the energy of a vehicle during a collision and redirect it in a controlled manner to reduce the severity of accidents. Metal beam crash barriers are particularly effective at preventing vehicles from hitting dangerous roadside objects, steep drops, or other hazards.

Key Features of a Metal Beam Crash Barrier:

-

High Strength and Durability:

-

Metal beams are constructed from steel or other durable metals, making them strong enough to withstand high-impact collisions. They can endure the stresses of repeated impact without significant wear or failure, offering long-term durability.

-

-

Energy Absorption:

-

The primary function of a metal beam crash barrier is to absorb the kinetic energy from a vehicle during an impact. The barrier's design helps to reduce the force exerted on the vehicle and its occupants, preventing more severe damage or injury.

-

-

Redirection and Containment:

-

Metal beam barriers are designed to redirect vehicles back onto the road in the event of a collision, rather than allowing them to crash into surrounding objects or areas. This containment helps keep vehicles in a safe zone.

-

-

Flexible and Adjustable:

-

These barriers are often flexible and designed to bend or deflect upon impact. The flexibility helps to slow the vehicle gradually, decreasing the risk of injury and allowing for controlled deceleration.

-

-

Corrosion Resistance:

-

Metal beam crash barriers are typically galvanized or coated with anti-corrosion materials to protect against rust and degradation due to exposure to weather conditions. This ensures the barrier maintains its strength and effectiveness over time.

-

-

Visibility:

-

Many metal beam barriers are painted with bright colors, reflective markings, or mounted with reflective panels to enhance visibility, especially in low-light or nighttime conditions. This helps drivers clearly see the barrier and reduce the chances of a collision.

-

Types of Metal Beam Crash Barriers:

-

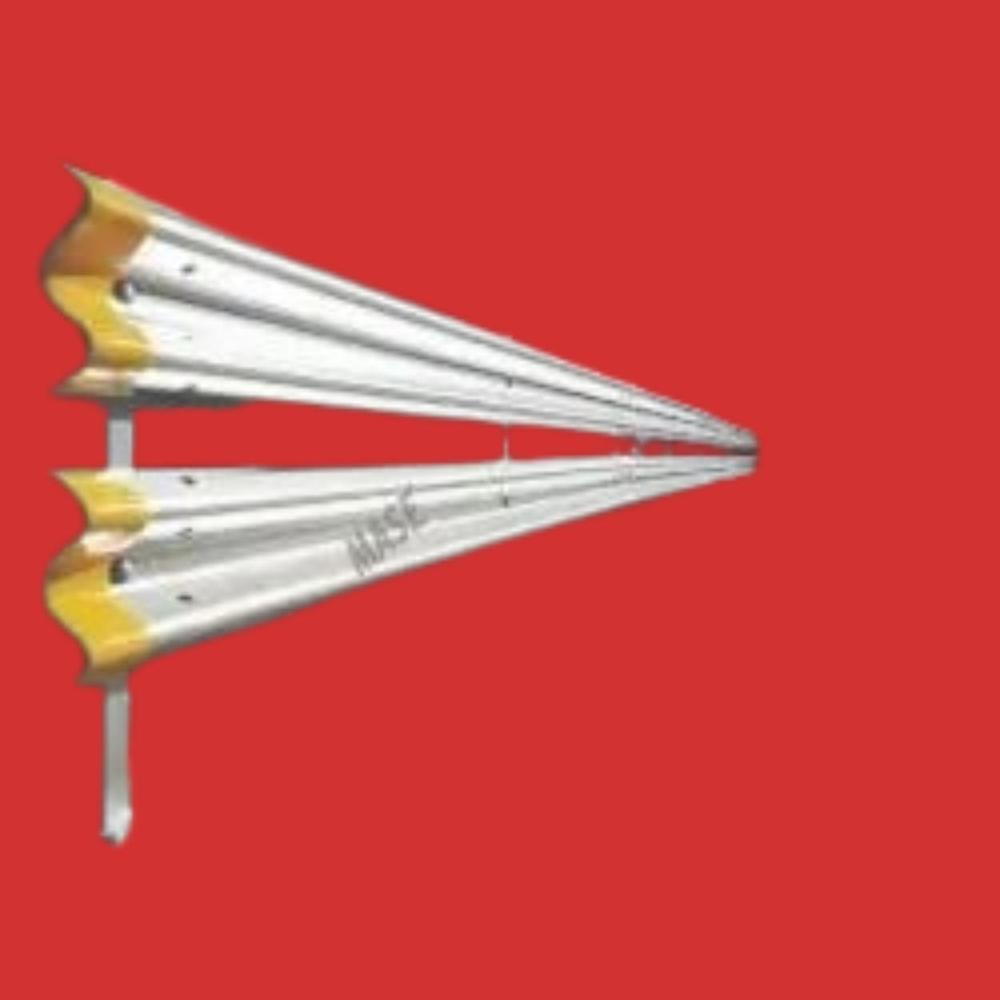

W-Beam Crash Barrier:

-

The W-beam is one of the most commonly used types of metal beam barriers. It features a "W" shaped cross-section, which provides both strength and flexibility. The W-beam can bend on impact, absorbing energy and redirecting the vehicle away from the hazard.

-

This design is often used on highways and roads where higher-speed impacts are a concern.

-

-

Thrie-Beam Crash Barrier:

-

The Thrie-beam barrier consists of three beams arranged in a vertical orientation. It provides additional strength and durability compared to the W-beam, making it suitable for roads with high-speed traffic or areas that experience frequent collisions.

-

Thrie-beam barriers are commonly used in more challenging environments, such as areas with limited space or heavy traffic.

-

-

Box Beam Crash Barrier:

-

Box beam barriers are made from hollow steel beams and are used in areas requiring higher impact resistance. The enclosed box structure provides a high level of containment and is often used on bridges or locations with significant potential hazards.

-

Applications of Metal Beam Crash Barriers:

-

Highways and Roads:

-

Metal beam barriers are primarily installed on highways and main roads to prevent vehicles from swerving off the road and colliding with obstacles such as trees, cliffs, or other dangerous areas.

-

-

Bridges and Overpasses:

-

These barriers are commonly used on bridges, where the risk of vehicles falling off the road due to high traffic speeds or curves is higher. The barriers help ensure the safety of drivers, particularly in elevated or precarious positions.

-

-

Construction Zones:

-

Metal beam crash barriers are often used in temporary safety installations in construction zones to protect workers and vehicles from oncoming traffic.

-

-

Urban and Residential Areas:

-

These barriers are also installed in areas near residential neighborhoods, parks, or other locations where pedestrian safety is a concern.

-

-

Rural and Hazardous Roads:

-

On rural roads or winding paths with poor visibility, metal beam barriers help prevent drivers from veering off the road, especially when there are sharp curves or ditches nearby.

-

Benefits of Metal Beam Crash Barriers:

-

Cost-Effectiveness:

-

Metal beam crash barriers are generally affordable compared to other road safety measures, especially in terms of material costs and ease of installation.

-

-

Maintenance:

-

These barriers are relatively low maintenance, requiring occasional inspections and repairs, but they typically have a long lifespan due to their durable construction and resistance to weathering.

-

-

Safety:

-

The primary benefit of metal beam crash barriers is their ability to reduce the risk of injury in the event of a collision. By redirecting vehicles and absorbing impact energy, these barriers help reduce fatalities and serious injuries.

-

-

Ease of Installation:

-

Metal beam barriers are easy to install and can be quickly set up along roads and highways. They are typically mounted on steel posts or concrete foundations, which ensures stability and durability.

-

Maintenance and Inspection:

-

Regular Inspections: These barriers should be regularly inspected for signs of damage, wear, or corrosion. Cracks, bends, or significant dents in the metal beams can compromise the barriers effectiveness and should be repaired immediately.

-

Cleaning: Over time, dirt and debris can accumulate on the surface of the barrier. Routine cleaning ensures the visibility and structural integrity of the barrier.

-

Repairs: After a crash or impact, metal beam barriers must be repaired to restore their function. Damaged sections should be replaced promptly to maintain safety standards.

Conclusion:

Metal beam crash barriers are an essential part of road safety infrastructure, offering a reliable solution to mitigate the impact of accidents and keep road users safe. Their strength, flexibility, and ability to absorb energy make them highly effective in high-speed environments where the risk of accidents is significant. Whether on highways, bridges, or construction zones, these barriers provide critical protection to prevent serious accidents and fatalities.

Would you like more specific information on materials, installation, or manufacturers of metal beam crash barriers? Let me know if you'd like further details!A Metal Beam Crash Barrier is a safety feature commonly used along highways, roads, and in areas where vehicles may be at risk of veering off course. These barriers are designed to absorb and redirect the energy from an impact, preventing vehicles from going off the road or crashing into dangerous objects. They help minimize injury to drivers, passengers, and pedestrians.

Key Features of Metal Beam Crash Barriers:

-

Material: Made of steel or other durable metals, these barriers are designed to withstand significant impact forces.

-

Design: They usually consist of multiple steel beams, mounted on posts, that can flex and absorb the energy from a collision, reducing damage to the vehicle and its occupants.

-

Types:

-

W-beam: The most common type of barrier, characterized by its "W" shape, which allows for energy absorption and is cost-effective.

-

Thrie-beam: A more robust version, featuring three beams for added strength, often used in areas with higher-speed traffic.

-

Cable Barriers: Made of high-tensile steel cables, used as an alternative to metal beam barriers in certain areas.

-

-

Applications: Used on highways, at intersections, along bridges, and near roadside obstacles like trees or signposts.

-

Height: Typically ranges from 27 inches to 36 inches, depending on the type and location of the barrier.

-

End Treatments: To prevent vehicles from hitting the sharp end of the barrier, special end treatments like terminal ends or attenuators are installed.

Do you need any details on installation, specific manufacturers, or maintenance of these barriers? Feel free to let me know!

Reliable Protection for Road Safety

Engineered to absorb and deflect impacts, this metal beam crash barrier safeguards roadways, commercial premises, and industrial areas. The silver steel construction is chosen for its high strength-to-weight ratio, achieving superior safety performance without unnecessary bulk. Installers and safety engineers throughout India trust this solution to minimize vehicle damage and enhance roadside safety.

Versatile Applications Across Sectors

Designed for broad utility, this crash barrier suits diverse usage in highways, factories, logistics parks, and commercial zones. Its standard size allows for seamless integration with existing road infrastructure. The outlet caters to a large customer base, from suppliers and traders to manufacturers and fabricators, supporting extensive safety needs in India's evolving landscapes.

FAQ's of Metal Beam Crash Barrier:

Q: How is a metal beam crash barrier installed and maintained?

A: Installation involves anchoring the steel barriers to the ground or concrete foundations along road edges or medians. Professional installation ensures proper alignment and structural stability. Maintenance generally includes routine inspections for damage or corrosion and replacing any affected sections as needed.Q: What materials are used in the construction of these crash barriers?

A: The crash barriers are made from high-quality steel, finished in a silver color to provide both strength and resistance to environmental factors. This choice of material offers excellent durability and impact absorption for road safety.Q: Where are metal beam crash barriers typically used?

A: These barriers are commonly installed on highways, expressways, commercial complexes, and industrial facilities across India to improve safety by reducing the risk and severity of vehicle run-offs or collisions.Q: What does the installation process entail for dealers and fabricators?

A: Dealers and fabricators must coordinate with certified installers to ensure barriers are anchored securely. Proper handling of the 45 kg units and adherence to installation guidelines is essential for optimal performance and longevity.Q: How do metal beam crash barriers benefit road safety?

A: They help prevent vehicles from veering off roadways, reduce accident severity, and protect drivers and property. The robust steel structure is especially effective in high-traffic or hazardous zones, providing a critical layer of defense.Q: Who can purchase these crash barriers in India?

A: A wide range of customers can acquire these barriers, including dealers, manufacturers, fabricators, suppliers, traders, wholesalers, and retailers. The product is suitable for both small-scale and large-scale safety projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bridge Expansion Joint Category

STRIP SEAL EXPANSION JOINT

Price 3000.00 INR / Meter

Minimum Order Quantity : 1 Meter

Thickness : 10 Millimeter (mm)

Color : Silver

Material : Mild Steel

Bridge Expansion Joints

Price 3000.0 INR / Meter

Minimum Order Quantity : 25

Thickness : Variable thickness depending on the joint type typically ranges from 10mm to 50mm Inch

Color : Blue and black

Material : Steel and rubber composite

Structure : Robust modular design

16mm Mastic Pad

Price 280.00 INR / Meter

Minimum Order Quantity : 1 Meter

Thickness : 6 Millimeter (mm)

Color : Gray

Material : PVC

Industrial Compression Rubber Seal

Price 450.0 INR

Minimum Order Quantity : 1 Meter

Thickness : Varies (customizable as per requirements)

Color : Black

Material : Industrial Grade Rubber

Structure : Extruded profile, seamless loop

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free