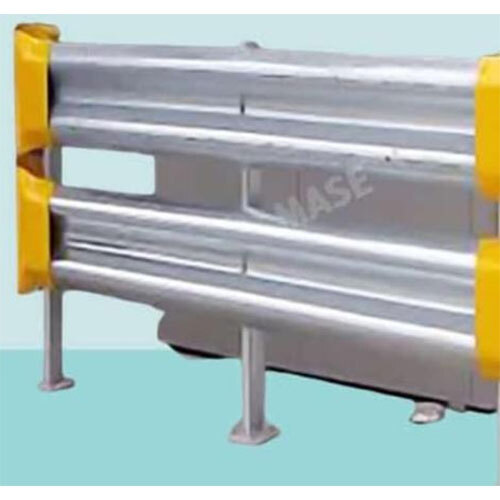

Single Side Double Beam Crash Barrier

Price 2400.00 INR/ Meter

Single Side Double Beam Crash Barrier Specification

- Material

- Galvanized Iron

- Thickness

- 6 Millimeter (mm)

- Power Supply

- Highway

- Display Type

- No

- Usage

- Single-sided double beam crash barriers are essential safety

- Size

- 3X5X1800 mm

- Color

- Silvar

About Single Side Double Beam Crash Barrier

A Single Side Double Beam Crash Barrier is a type of road safety barrier used to protect vehicles and pedestrians from accidents by preventing vehicles from veering off the road. The "double beam" part refers to the two parallel beams that make up the barrier, providing a higher level of containment and protection than a single beam barrier. These barriers are typically used in high-traffic or high-speed areas where there is a significant risk of vehicles straying off the road, such as highways, bridges, or areas with sharp curves.

Key Features of a Single Side Double Beam Crash Barrier:

-

Two Parallel Beams:

-

The barrier consists of two beams (often W-beams or thrie-beams) that are mounted on the same side of the road. This dual beam design increases the strength of the barrier, providing added resistance to higher-impact collisions.

-

-

Enhanced Containment:

-

The double beam design offers improved containment compared to a single beam. The extra beam helps reduce the risk of a vehicle breaking through the barrier or veering off the road, especially in situations where vehicles may be traveling at higher speeds or in areas where there is a higher risk of collisions.

-

-

Energy Absorption:

-

The design of the beams allows them to absorb the impact energy from a vehicle collision. The energy is dissipated as the vehicle impacts and pushes against the beams, gradually decelerating the vehicle. This reduces the severity of the crash and the risk of injury to occupants.

-

-

Flexibility and Deflection:

-

Like other metal beam barriers, a single-side double beam barrier is designed to bend and deflect upon impact, rather than remaining rigid. This deflection helps to absorb the kinetic energy and ensures that the barrier does not cause additional harm to the vehicle or its occupants.

-

-

Steel Posts and Mounting:

-

The beams are typically mounted on vertical steel posts or concrete foundations, which are spaced evenly along the length of the barrier. These posts hold the beams in place and allow for controlled deflection during a collision.

-

-

Corrosion Resistance:

-

The beams are usually galvanized or coated with a protective layer to prevent rust and corrosion due to exposure to weather and environmental elements. This ensures the long-term durability and effectiveness of the barrier.

-

Applications of a Single Side Double Beam Crash Barrier:

-

Highways and Expressways:

-

Single side double beam crash barriers are commonly used on highways and expressways where traffic speeds are high. The barrier provides added protection by reducing the likelihood of a vehicle crossing into oncoming traffic or hitting dangerous roadside objects.

-

-

Bridges and Overpasses:

-

These barriers are also used on bridges, overpasses, or elevated highways where the consequences of a vehicle leaving the roadway are more severe (e.g., falling from a height or crashing into structures below).

-

-

Sharp Curves or Intersections:

-

Roads with sharp curves or intersections, where there is a higher risk of vehicles losing control, often use double beam crash barriers to help prevent cars from veering off the road.

-

-

Construction Zones:

-

In temporary roadwork or construction zones, these barriers are used to protect workers from oncoming traffic and to contain vehicles that might go off the road.

-

-

Rural or Dangerous Roads:

-

In rural or less-developed areas with winding roads, steep inclines, or dangerous roadside features (like cliffs or ditches), a double beam barrier can provide the necessary protection to keep vehicles from veering off the road.

-

Benefits of a Single Side Double Beam Crash Barrier:

-

Improved Safety:

-

The main benefit of a double beam crash barrier is its enhanced safety. The two beams provide additional strength and containment, which increases the chances of stopping a vehicle before it leaves the road or crashes into dangerous objects.

-

-

Energy Absorption:

-

The dual beams work together to absorb more energy during a collision, reducing the force exerted on the vehicle and its occupants. This helps reduce the severity of the crash.

-

-

High-Impact Resistance:

-

The double beam design provides greater resistance to higher-impact collisions, making it ideal for areas with higher traffic speeds and more frequent accidents.

-

-

Long-Term Durability:

-

With proper installation and maintenance, these barriers have a long lifespan. The steel beams are designed to withstand harsh weather conditions, and the corrosion-resistant coatings help prevent degradation over time.

-

-

Flexibility in Design:

-

These barriers are flexible in design and can be adapted to different traffic needs or specific roadway conditions. They can be used as standalone barriers or as part of a larger safety system in high-risk areas.

-

Installation and Maintenance:

-

Installation:

-

The barrier is installed by securing the steel posts or concrete foundations into the ground at regular intervals along the roadside. The beams are then mounted onto these posts using special fittings that allow the barrier to flex upon impact.

-

Proper alignment and spacing of the posts are crucial to ensure that the barrier functions as intended, especially when absorbing impact from collisions.

-

-

Maintenance:

-

Regular Inspections: The barriers should be inspected regularly for signs of wear and damage, such as rust, dents, or bending. If any sections are damaged, they should be repaired or replaced promptly.

-

Cleaning: Keeping the barrier clean of dirt, debris, and vegetation ensures that reflective panels and visibility markings remain effective.

-

Repairs: After a collision or impact, the barrier may need to be realigned or repaired. Sections of the metal beams or posts may need to be replaced, depending on the severity of the damage.

-

Conclusion:

A Single Side Double Beam Crash Barrier is a robust and effective solution for enhancing road safety in high-risk areas. Its design offers improved containment, better energy absorption, and higher resistance to impacts compared to single-beam barriers, making it an ideal choice for locations with higher traffic speeds or greater collision risks. These barriers are essential in keeping vehicles on the road and preventing accidents that could result in serious injury or property damage.

Would you like more specific information on installation guidelines, or are you interested in details about a particular manufacturer or product? Let me know!

Superior Roadside Safety

Our single-sided double beam crash barriers are meticulously designed to maximize roadside protection. Manufactured using high-quality galvanized iron, these barriers are corrosion-resistant and highly durable even under harsh weather. With a thickness of 6 mm, they effectively absorb impact, preventing vehicles from leaving the roadway and reducing accident severity. Their silver finish blends well into highway environments, making them both practical and visually appealing.

Precision Engineering & Easy Installation

Every barrier is produced to stringent specifications-measuring 3X5X1800 mm-which ensures compatibility with standard highway layouts. Their modular design enables swift installation by professionals, minimizing traffic disruption. Their construction is tailored for quick deployment whether you're a dealer, fabricator, or government contractor. These barriers require no external power supply, making them cost-effective and maintenance-friendly options for long-term road safety.

FAQ's of Single Side Double Beam Crash Barrier:

Q: How is the single side double beam crash barrier installed on highways?

A: These crash barriers are installed along road edges using a series of anchor bolts and posts. Their modular size (3X5X1800 mm) allows for seamless alignment and connection, making them suitable for swift roadside deployment without the need for a power supply.Q: What is the benefit of using galvanized iron in these crash barriers?

A: Galvanized iron provides superior resistance to rust and corrosion, enhancing the longevity and reliability of the crash barrier. This makes it especially well-suited for outdoor highway environments where exposure to the elements is constant.Q: When should single side double beam crash barriers be preferred?

A: These barriers are ideal along highways, expressways, and elevated roads where there is a risk of vehicles veering off track. Their robust construction and single-sided design make them preferable for protecting one side of a road or highway in high-traffic or hazardous areas.Q: Where can I source these crash barriers in India?

A: You can obtain these crash barriers from a network of dealers, fabricators, manufacturers, producers, retailers, suppliers, traders, and wholesalers across India. Many companies offer bulk supply and installation services for highway projects.Q: What is the standard process for fabricating these crash barriers?

A: Manufacturing involves shaping galvanized iron into double beam profiles, then cutting and assembling units to the specified 3X5X1800 mm size. Quality checks are performed to ensure structural integrity before shipment to the installation site.Q: How are these barriers used effectively for highway safety?

A: They are used as a physical barrier to prevent vehicles from leaving the roadway, absorbing collision impact and minimizing damage and injuries during accidents, thus enhancing overall highway safety.Q: What are the key advantages for suppliers and installers of this crash barrier type?

A: Suppliers and installers benefit from the crash barrier's modularity, corrosion resistance, and standardized dimensions, which facilitate efficient handling, storage, quick installation, and long-term customer satisfaction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bridge Expansion Joint Category

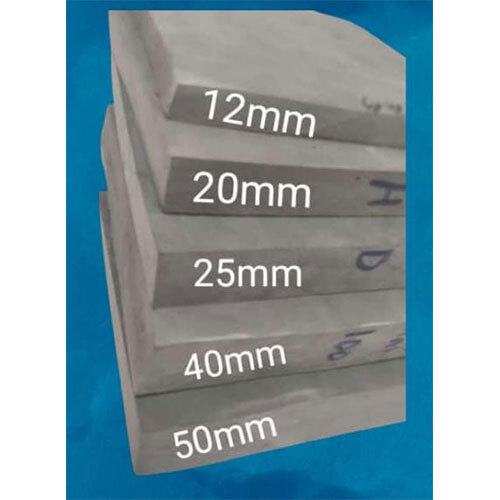

HD100 DURA BOARD

Price 350.0 INR / Piece

Minimum Order Quantity : 20 Pieces

Color : BLACK

Thickness : 12 Micrometers (um)

Usage : Expansion joints in concrete highways, airport runways, taxiways, and industrial flooring.

Size : 12,15,20,25

Neoprene Strip Seal for Bridge Expansion Joint

Price 450.0 INR / Meter

Minimum Order Quantity : 1 Meter

Color : Balck

Thickness : 4 Millimeter (mm)

Usage : Bridge

Size : 150mm

Monolithic F Type Strip seal Expansion Joint

Price 140.00 INR / Meter

Minimum Order Quantity : 1 Meter

Color : Gray

Thickness : 6 Millimeter (mm)

Usage : Pneumatic Connections

Size : 3/4 inch

T Type Strip Seal Expansion Joint

Price 3600.00 INR / Meter

Minimum Order Quantity : 1 Meter

Color : Blue

Thickness : 6 Millimeter (mm)

Usage : Industrial Use,Bridges, Highways, Buildings, Infrastructure

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS