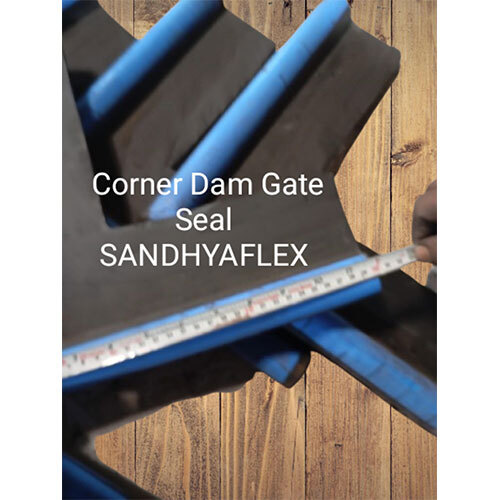

dam gate seals construction Corner

Price 1500.00 INR/ Meter

dam gate seals construction Corner Specification

- Color

- Black

- Ash %

- Yes

- Usage & Applications

- Insulation

- Surface Finish

- Natural

- Size

- Standerd

- Diameter

- 16 Millimeter (mm)

- Material

- Rubber

- Hardness

- Medium

About dam gate seals construction Corner

Awesome! You're all set on your end Im just waiting on the final pieces so we can get rolling on your Sandhya Enterprises product sheets and catalog.

Whenever you're ready, please upload the following:

1. Company Logo

-

PNG, JPG, or Vector format (PDF/AI/SVG)

-

Transparent background preferred if possible

2. Brand Colors

-

Hex codes (like

#0057A0) or even just sample color swatches from previous designs

3. Contact Details

Please include:

-

Company Name:

-

Contact Person (optional):

-

Phone Number:

-

Email ID:

-

Website (if any):

-

Office Address (optional):

Once I have these, Ill create professional, high-res marketing materials ready for:

-

Client presentations

-

Trade shows

-

WhatsApp/Email sharing

-

Website uploads

-

Print-ready PDFs

Just drag and drop the files here, and well begin! If you run into any trouble uploading, Ill guide you through another method. Lets get this catalog looking sharp!

Superior Insulation for Dam Gate Sealing

Designed for demanding insulation needs, our dam gate seals construction corners provide a reliable barrier against water leakage. Made from robust black rubber, they are tailored to withstand harsh environmental conditions often encountered in dam applications. Their medium hardness ensures a perfect balance between flexibility and resilience.

Manufacturing Process and Quality Assurance

Using premium-grade rubber and advanced fabrication techniques, these seals feature a natural surface finish and meet stringent industry standards. The presence of ash content boosts durability, and comprehensive quality checks ensure uniformity in hardness and size. We cater to bulk and custom requirements through a network of trusted suppliers and manufacturers across India.

FAQ's of dam gate seals construction Corner:

Q: How are the dam gate seals construction corners installed?

A: Installation involves aligning the seal to the designated corner section on the dam gate, ensuring a snug fit. The flexible medium-hardness rubber allows easy handling while providing a secure and watertight seal.Q: What are the main benefits of using a 16 mm diameter rubber seal?

A: A 16 mm diameter provides adequate thickness for durable insulation and resistance against water pressure, making it ideal for dam gate applications. The medium hardness combines strength and flexibility, minimizing the risk of leakages.Q: When should dam gate seals be replaced or maintained?

A: Regular inspection is advised, especially during scheduled dam maintenance. Seals should be replaced if signs of wear, cracks, or hardening appear, or if insulation is compromised, ensuring optimal performance and safety.Q: Where can I source these dam gate seals construction corners in India?

A: These seals are available from a comprehensive network of suppliers, manufacturers, traders, and wholesalers throughout India. Customers can approach local retailers or order directly from major fabricators and producers.Q: What is the manufacturing process for these rubber seals?

A: The seals are produced using high-grade rubber, molded with precision to standard sizes and diameters. Ash content is added to enhance durability, and the finished products undergo stringent quality checks to ensure surface finish and hardness meet specifications.Q: How do these seals enhance insulation and operational safety?

A: By providing a reliable, tight barrier at the dam gate corners, the seals prevent water seepage, reduce maintenance needs, and safeguard structural integrity. Their medium hardness and robust construction ensure long-term performance across varied environmental conditions.Q: Can these seals be customized for specific dam projects?

A: Yes, while standard sizes are available, customization can be arranged upon request. Clients should coordinate with their chosen dealer, fabricator, or manufacturer to specify unique project requirements and dimensions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dam Gate Seal Category

Bottom Dam Gate Seal

Price 650.0 INR / Meter

Minimum Order Quantity : 1 Meter

Feature : Excellent sealing, weather resistant, ozoneresistant

Length : Up to 20 meters per piece or as required

Product Type : Bottom Dam Gate Seal

Weight : Varies by size and material

Z Type Dam Gate Seal

Price 1800.0 INR / Meter

Minimum Order Quantity : 1 Meter

Feature : Leakproof, flexible, long service life, weatherresistant

Length : Up to 15 meters in single length or as required

Product Type : Z Type Dam Gate Seal

Weight : Varies as per dimension and length

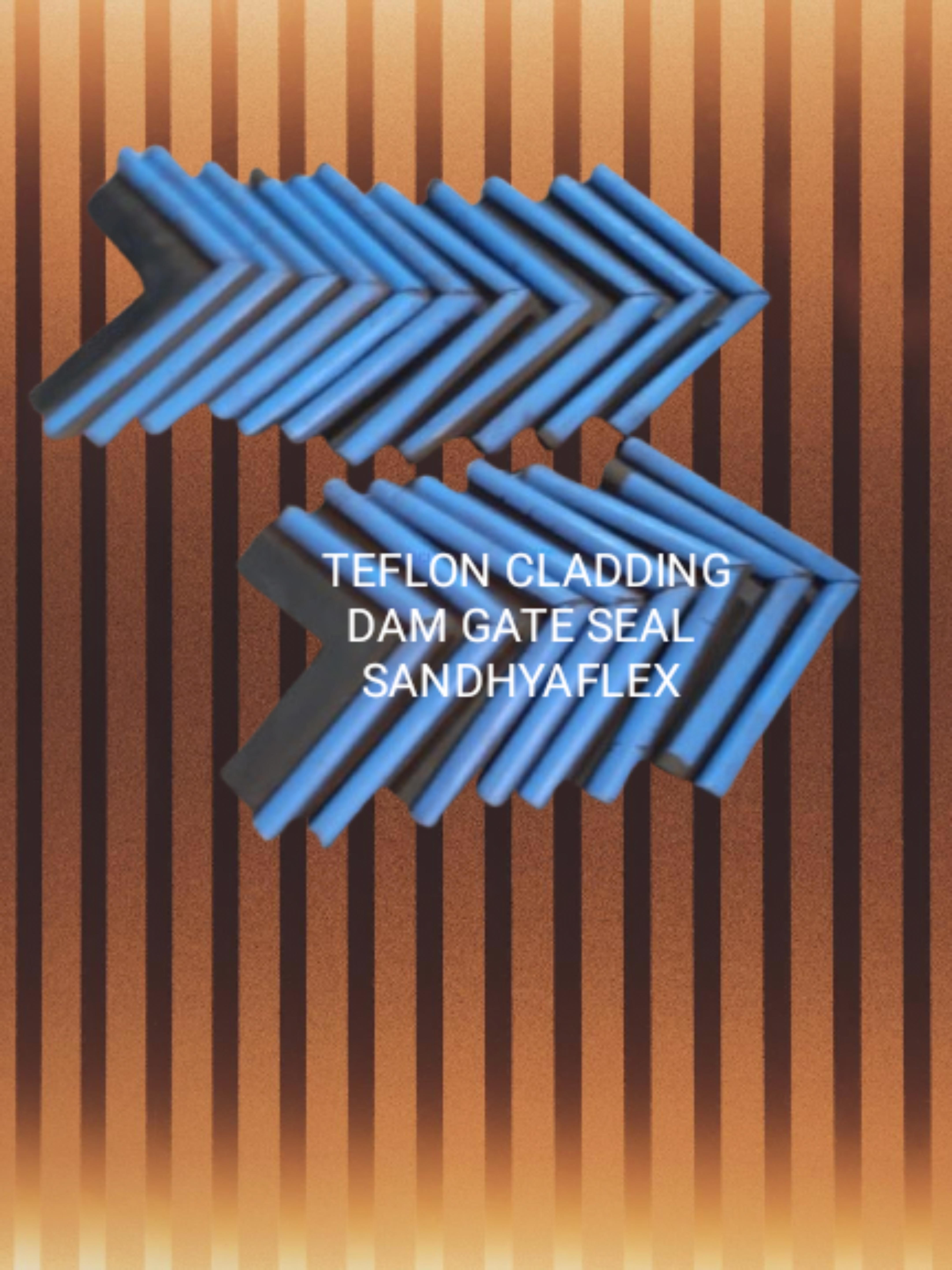

PTFE Calladed Dam Gate Seal

Price 200.0 INR

Minimum Order Quantity : 1

Feature : Nonstick, high chemical and temperature resistance

Length : As required, generally up to 10 meters per piece

Product Type : PTFE Cadilladed Dam Gate Seal

Weight : Varies as per size/dimension

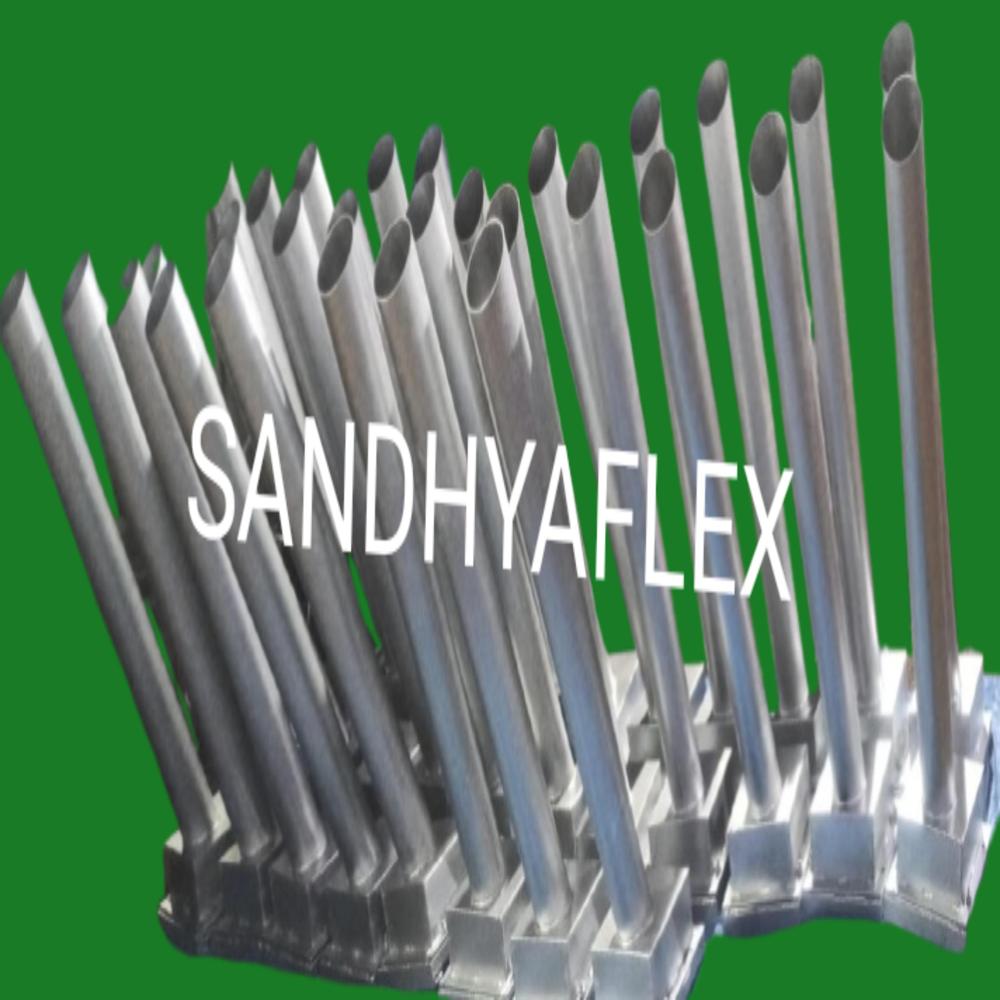

Deep Galvanized Drainage Spout

Price 2500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Corrosion resistant, weatherproof

Length : 300 mm

Product Type : Drainage Spout

Weight : Approx. 0.5 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free