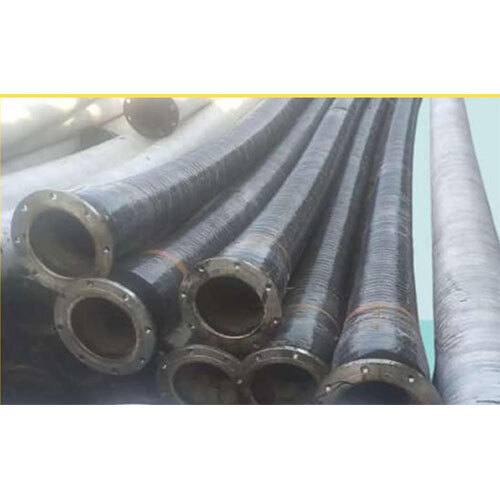

RUBBER OIL HOSE

RUBBER OIL HOSE Specification

- Cover

- rubber

- Connection Type

- flange

- Shape

- round

- Reinforcement

- ss wire

- Usage

- oil industries

- Material

- Rubber

- Size

- 3-12 inches

- Product Type

- RUBBER HOSE

- Inside Diameter

- 75 Millimeter (mm)

- Weight

- 45 Grams (g)

- Outside Diameter

- 90 Millimeter (mm)

- Color

- black

- Length

- 15 Meter (m)

- Warranty

- 6 months

RUBBER OIL HOSE Trade Information

- Minimum Order Quantity

- 1 Meter

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 30 Per Day

- Delivery Time

- 3 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wrapping

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- iso certificied

About RUBBER OIL HOSE

A rubber oil hose is a flexible, durable hose designed for the transfer of oil, fuel, or other petroleum-based fluids. These hoses are commonly used in automotive, industrial, marine, and agricultural applications.

Key Features of Rubber Oil Hoses

- Material Made from high-quality synthetic rubber, often reinforced with textile or steel braiding for added strength.

- Oil Resistance Specifically designed to resist oil, fuel, and other hydrocarbons without degrading.

- Temperature Resistance Can withstand high and low temperatures depending on the rubber composition.

- Pressure Rating Available in various pressure ratings, from low-pressure return lines to high-pressure hydraulic hoses.

- Flexibility Offers excellent flexibility for easy installation and movement.

Common Applications

- Fuel and oil transfer in vehicles

- Hydraulic systems

- Industrial machinery

- Marine fuel lines

- Oil cooling systems

Designed for Oil Industry Challenges

Built specifically for use in oil-related sectors, this rubber hose withstands harsh conditions, continuous flow, and exposure to chemicals. Its SS wire reinforcement and flange connection guarantee secure and reliable operations, making it perfect for infrastructure in oil fields, storage, and transportation.

Superior Durability and Convenience

With a rugged rubber cover, this hose resists abrasion and environmental damage, ensuring longevity. Lightweight and available in various diameters, it caters to a range of industrial needs, while the flexible material and secure connections facilitate quick installation and maintenance.

FAQ's of RUBBER OIL HOSE:

Q: How is the RUBBER OIL HOSE installed in oil industry applications?

A: The hose is typically installed using its flange connection, which allows for secure attachment to existing pipelines or machinery. SS wire reinforcement helps maintain the hose integrity and ensures it stays in place during operation.Q: What materials are used in the construction of this rubber oil hose?

A: This hose is made of high-quality rubber with SS wire reinforcement for extra strength and durability. The cover is also rubber, offering resistance to abrasion and harsh industrial environments.Q: When should this hose be replaced or maintained?

A: Generally, maintenance should be conducted regularly to inspect for wear or damage, with replacement recommended at the end of the hose's 6-month warranty or if any structural faults are identified sooner.Q: Where can I purchase the RUBBER OIL HOSE in India?

A: You can acquire this hose through various suppliers, including dealers, manufacturers, retailers, traders, and wholesalers across India.Q: What is the typical process for connecting this hose to equipment?

A: Connection is achieved using the built-in flange type, which involves securing the hose to compatible flanged fittings on equipment or pipelines. Professional installation is recommended to ensure a proper seal.Q: What are the primary uses and benefits of the RUBBER OIL HOSE?

A: This hose is used predominantly in oil industries to transport oil and related materials. Its robust design, flexibility, and resistance to environmental factors make it a reliable choice for continuous and heavy-duty operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Rubber Hoses Category

Black Color Rubber Strip

Price 55.0 INR / Meter

Minimum Order Quantity : 100

Material : Rubber

Hardness : 55 TO 65

Shape : Round

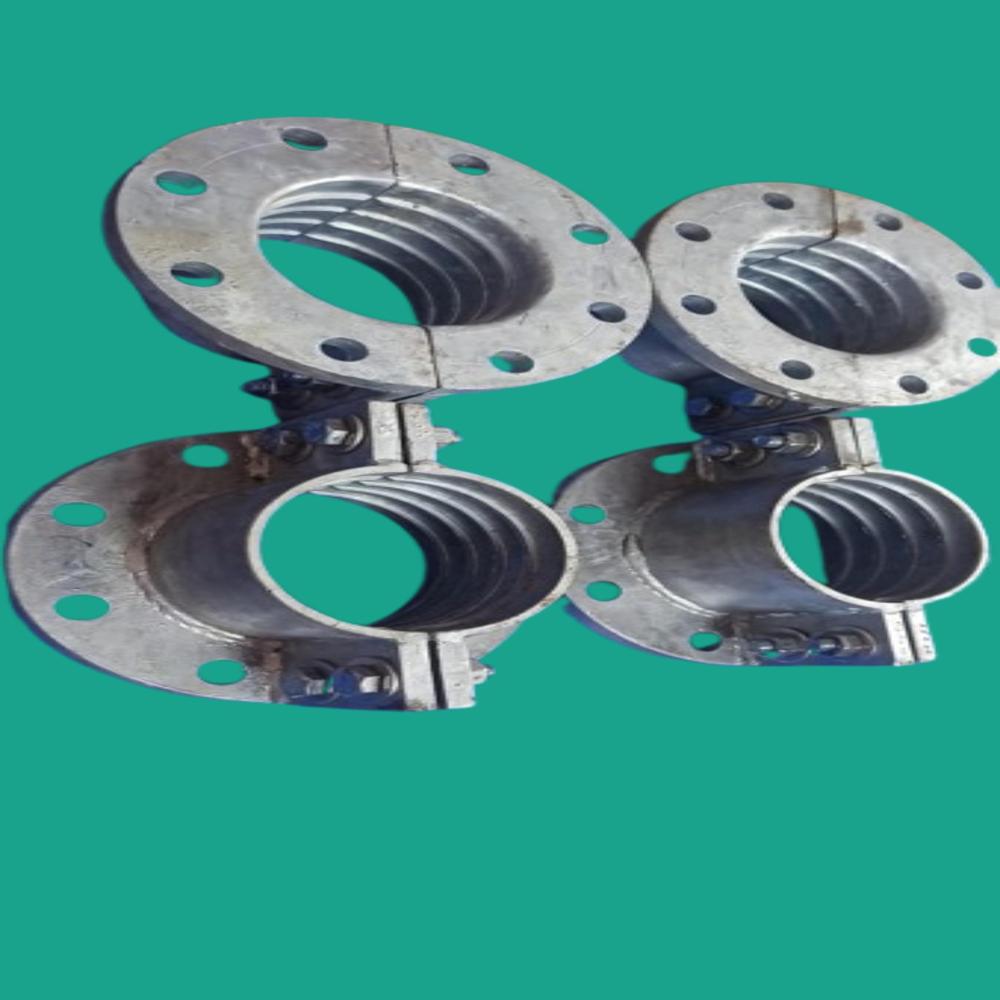

Spilet Flange

Price 4500.0 INR / Number

Minimum Order Quantity : 1 Number

Material : Other, Carbon Steel, Stainless Steel, Alloy Steel

Hardness : 160200 HB

Shape : Round

Medium : Other, Water, Oil, Gas

XLPE Chemical Rubber Hose

Price 650.0 INR / Meter

Minimum Order Quantity : 1 Meter

Material : Other, XLPE Lined Rubber Hose

Hardness : 65 5 Shore A

Shape : Round

Medium : Other, Chemicals, Acids, Alkalis, Solvents

RRL Fire Hose Pipe 63mm Type A

Price 3500.0 INR

Minimum Order Quantity : 1

Material : Other, 100% synthetic yarn with rubber lining

Hardness : Medium flexible

Shape : Round (Straight length)

Medium : Other, Fresh water and sea water

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free