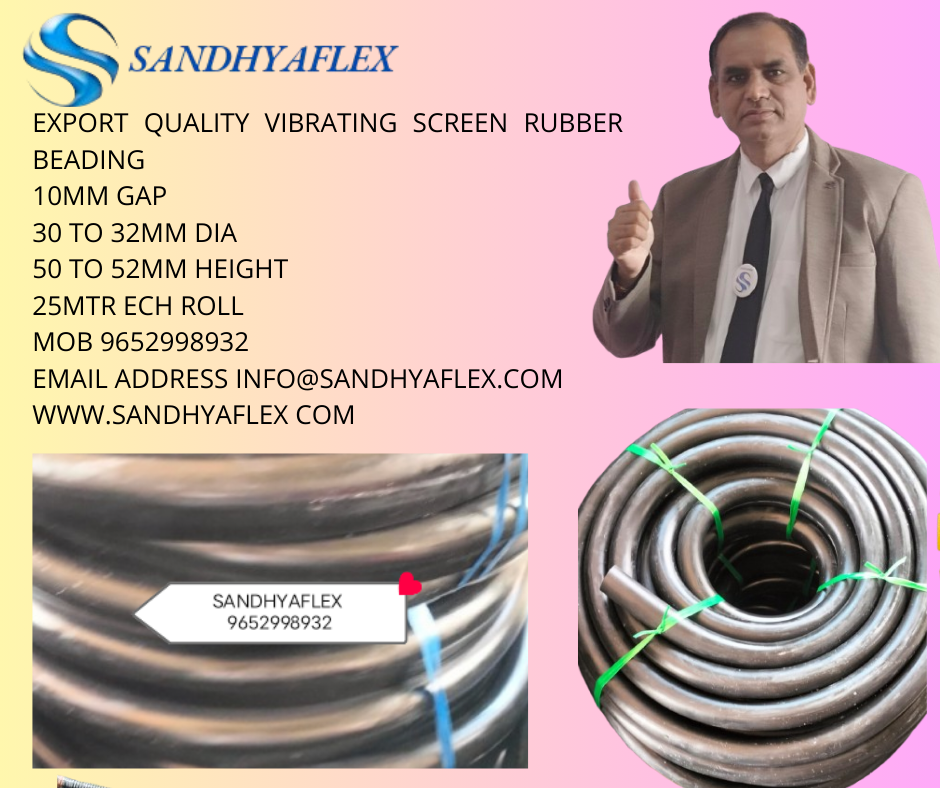

SANDHYAFLEX 10mm Gap Vibrating Screen Rubber Beading

SANDHYAFLEX 10mm Gap Vibrating Screen Rubber Beading Specification

- Rubber Type

- Natural Rubber/SBR

- Width

- Customizable/Standard widths as per requirement

- Weight

- Varies as per length and size (approx. 0.3-0.5 kg/m)

- Product Type

- Vibrating Screen Rubber Beading

- Style

- Rectangular/Flat Beading

- Volatile Matter (%)

- 3%

- Usage & Applications

- Used as a beading for vibrating screens in mining, quarrying, and other screening industries to protect mesh edges and reduce wear & tear.

- Diameter

- N/A (rectangular profile)

- Tensile Strength

- 12-15 MPa

- Density

- 1.3 Gram per cubic centimeter(g/cm3)

- Components

- Rubber, Additives, Stabilizers

- Flame Resistance Level

- Basic/Standard, not flame retardant

- Color

- Black

- Nitrogen Content (%)

- 1%

- Ash %

- Max 5%

- Thickness

- Up to 6mm

- Part Type

- Beading/Gasket/Seal

- Feature

- Highly elastic, weather-resistant, abrasion-resistant, anti-vibration

- Thermal Conductivity

- Low

- Temperature Resistance

- -25C to +80C

- Tolerance

- 0.5mm

- Resistance level

- Excellent Resistance to Wear & Tear

- Hardness

- 60 5 Shore A

- Compression Ratio

- Up to 30%

- Surface Finish

- Smooth matte finish

- Material

- Natural Rubber/Synthetic Rubber Blend

- Water Absorption

- Nil/Very Low

- Length

- Standard 10 Meters/roll, custom lengths available

- Size

- 10mm gap

- Natural Rubber

- Yes, Premium Natural Rubber Compound

About SANDHYAFLEX 10mm Gap Vibrating Screen Rubber Beading

Optimal Usage and Key Features

SANDHYAFLEX 10mm Gap Vibrating Screen Rubber Beading is designed for use in mining, quarrying, and screening industries, efficiently protecting mesh edges and minimizing wear. Direction of use includes cutting and fitting on-site as needed, allowing customization for any screen size. Key features encompass unrivaled elongation at break, superior elasticity, excellent ozone resistance, and high durability. Choose trimmed or untrimmed edges and enjoy easy installation for seamless screen protection and improved lifespan.

Premium Export Logistics and Delivery Rates

SANDHYAFLEX 10mm Gap Vibrating Screen Rubber Beading is shipped from a major FOB port in India to global destinations. Our premium logistics ensure prompt and safe delivery to main export markets including Asia, Middle East, Africa, and Europe. Expect reliable service and competitive rates; delivery time typically ranges between 1015 days, excelled by efficient packaging and streamlined handling. Partner with SANDHYAFLEX for uncompromised product quality and timely supply worldwide.

FAQs of SANDHYAFLEX 10mm Gap Vibrating Screen Rubber Beading:

Q: How is SANDHYAFLEX 10mm Gap Vibrating Screen Rubber Beading installed on-site?

A: The beading is simple to install; it can be easily cut to the required lengths and fitted directly onto vibrating screens, ensuring seamless edge protection and customization as per site requirements.Q: What features distinguish this rubber beading from others in the market?

A: SANDHYAFLEX offers unrivaled elongation at break (>300%), premium natural rubber blend, excellent ozone resistance, superior elasticity, easy installation, and compliance with ISI & ISO 9001:2015 standards.Q: When is the ideal time to replace the beading on vibratory screens?

A: Replacement is suggested when noticeable wear, edge tearing, or loss of elasticity occurs, typically after extended periods of operation or if routine inspections indicate diminished protection.Q: Where can I procure SANDHYAFLEX Vibrating Screen Rubber Beading?

A: You can purchase directly from SANDHYAFLEX as a dealer, supplier, manufacturer, or retailer. The product is available across India and distributed to various international exporters and traders.Q: What is the process for customizing width and length requirements?

A: Simply specify your desired measurements when placing your order. SANDHYAFLEX offers both standard rolls and custom lengths or widths to precisely fit your screening equipment and project needs.Q: How does using SANDHYAFLEX beading benefit industrial operations?

A: This rubber beading provides grand protection against mesh damage, absorbs vibration, reduces wear, and enhances the operating life of vibrating screens, ultimately saving costs on repairs and replacements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

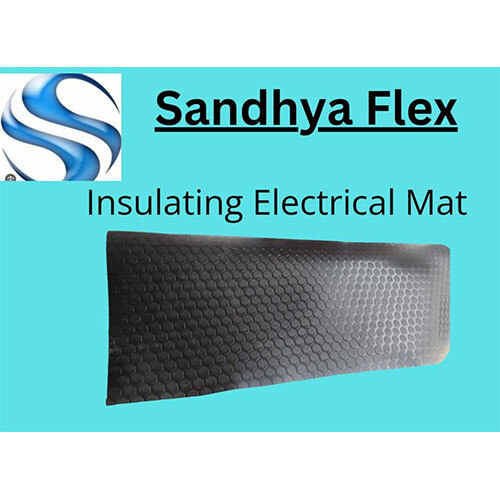

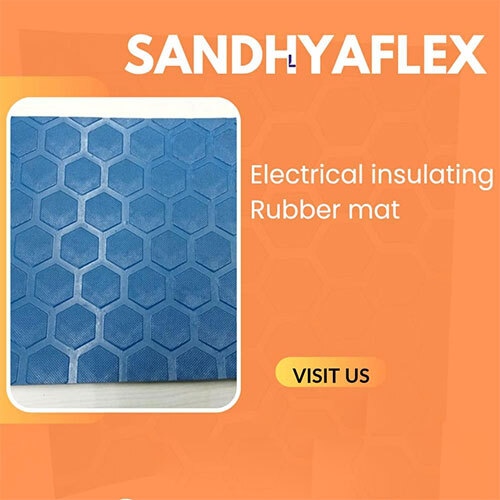

Electrical Insulating Sheet

Price 400.0 INR / Meter

Minimum Order Quantity : 10

Usage & Applications : It is commonly used in electrical applications, flooring, industrial sealing, and vibration damping.

Size : 3

Color : BLACK

Material : RUBBER

Cement feeding rubber hose

Price 1800.00 INR / Meter

Minimum Order Quantity : 5

Usage & Applications : Insulation

Size : Standerd

Color : Black

Material : Rubber

swellable water stopper

Price 180.0 INR / Meter

Minimum Order Quantity : 1 Meter

Usage & Applications : Industrial

Size : Standard

Color : Red

Material : Rubber

Electrical Insulating Mat 2.5mm

Price 500.00 INR / Square Meter

Minimum Order Quantity : 1 Square Meter

Usage & Applications : Insulation

Size : 2.5mm

Color : Blue

Material : PVC

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS