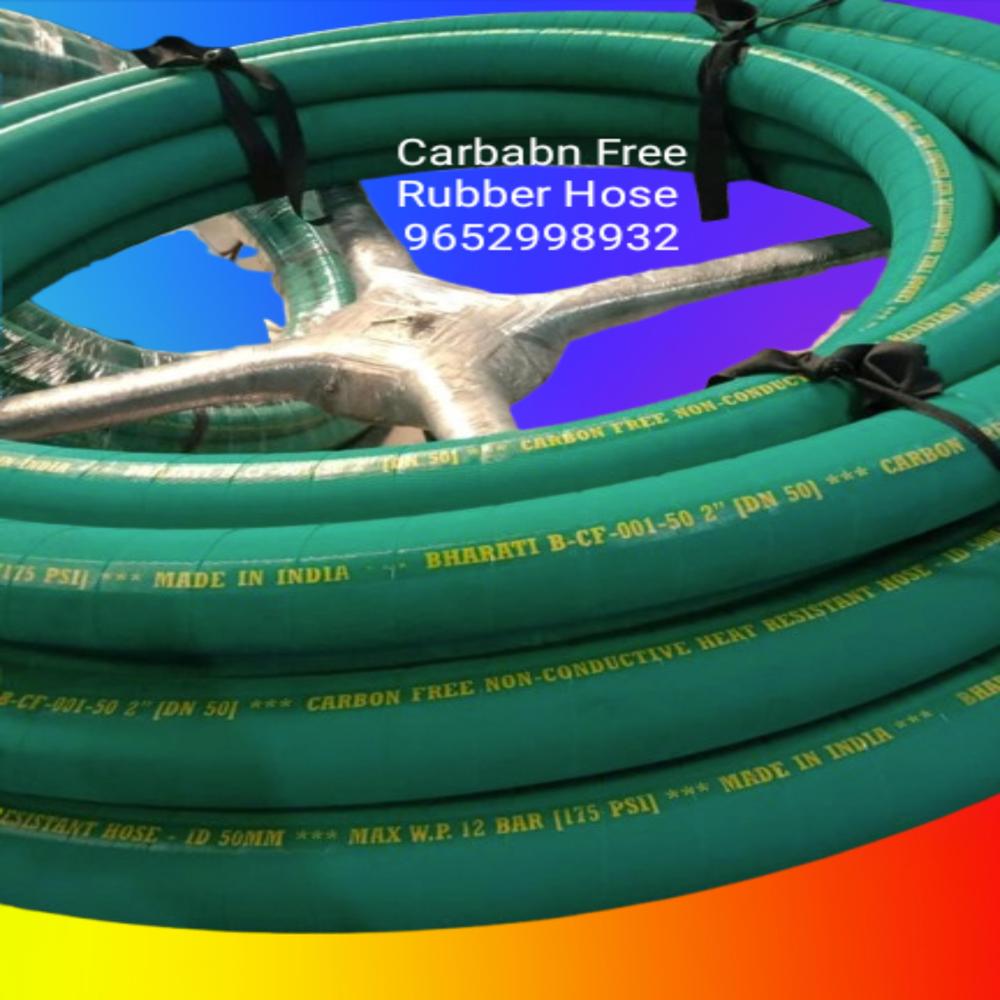

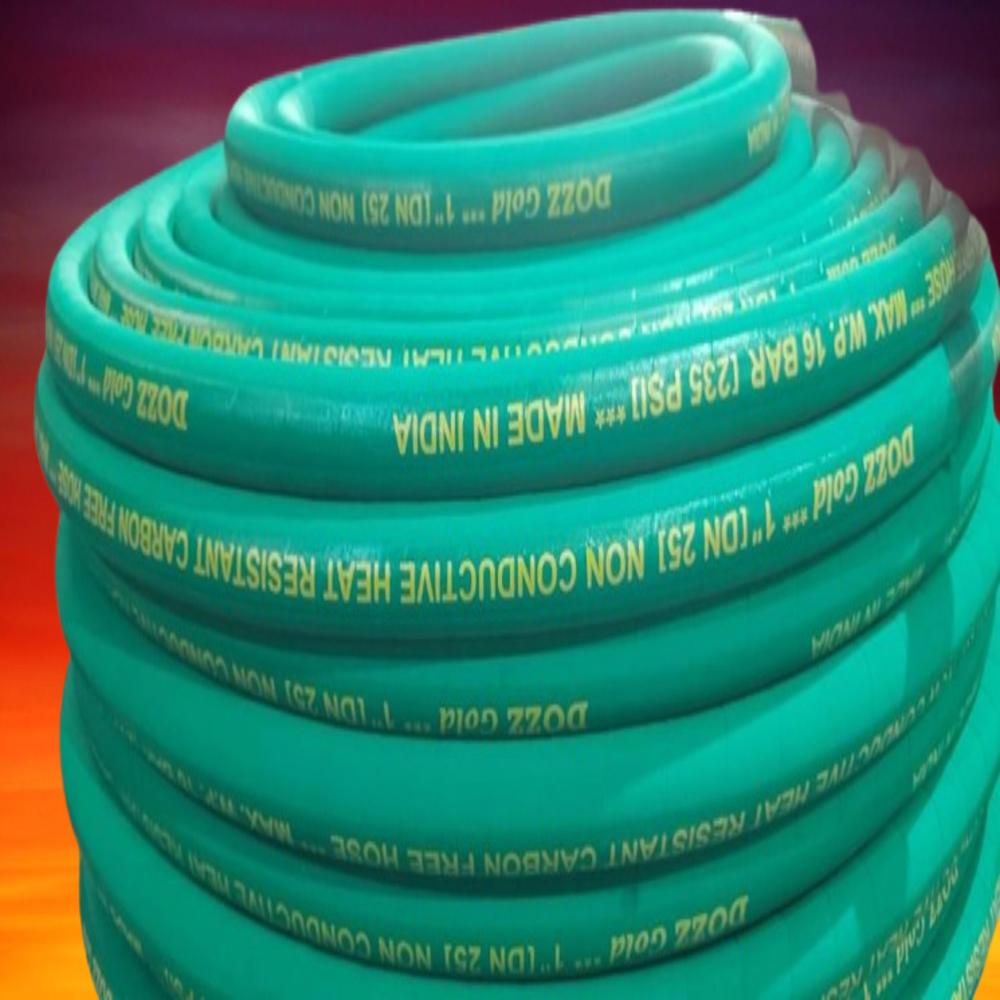

Carbon Free Rubber Hose

Price 240.0 INR/ Meter

Carbon Free Rubber Hose Specification

- Reinforcement

- Synthetic Textile Plies with Copper Wire

- Hardness

- 70 5 Shore A

- Connection Type

- Flanged / Plain End / Threaded

- Medium

- Electric Power Cables / Cooling Water

- Shape

- Round

- Cover

- Orange Color, Abrasion Resistant Rubber

- Material

- High Grade Non-Conductive Rubber

- Temperature

- -40C to +100C

- Pressure

- 15 Bar (217 psi)

- Inside Diameter

- 12 mm to 50 mm

- Outside Diameter

- 22 mm to 62 mm

- Minimum Bend Radius

- 150 mm

- Conductivity

- Carbon Free, Electrically Non-Conductive

- Burst Pressure

- Up to 45 Bar

- Customization

- Available as per client requirements

- Packing Type

- Coiled & Wrapped

- Temperature Resistance

- Excellent heat and weather resistance

- Surface Finish

- Smooth

- Working Environment

- Suitable for indoor/outdoor installations

- Length

- Up to 30 meters

- Color

- Orange

- Application

- Used in electrical power plants, steel mills, glass plants for cooling and protecting power cables

About Carbon Free Rubber Hose

A Carbon Free Rubber Hose is a specialized electrical insulation hose used mainly in furnace cooling and high-temperature electrical applications, where no carbon particles can be present to avoid conductivity.

Heres a breakdown to help you understand or specify it:

What is a Carbon Free Rubber Hose?

Its a highly flexible, non-conductive rubber hose used to circulate water or other coolants in electrical furnaces, induction furnaces, arc furnaces, etc., while eliminating any risk of electrical conductivity.

Key Applications

-

Steel plants (induction furnace cooling)

-

Foundries

-

Electrical and thermal plants

-

Welding and plasma cutting units

Typical Specifications

| Feature | Description |

|---|---|

| Inner Diameter (ID) | Common sizes: 12mm, 19mm, 25mm, 32mm, etc. |

| Outer Diameter (OD) | Varies depending on ID & wall thickness |

| Wall Thickness | Usually 4mm6mm |

| Length | Usually supplied in 10m or 15m rolls |

| Working Pressure | 1015 bar (150220 psi) |

| Temperature Range | -40C to +100C (some up to 120C) |

| Color | Usually Blue, sometimes Green or Red |

| Reinforcement | High-tensile synthetic textile braid |

| Electrical Resistivity | High (Non-conductive, anti-static) |

| Surface Finish | Smooth or cloth-wrapped for flexibility |

Features & Benefits

-

Completely carbon-free zero risk of conductivity

-

High flexibility easy to route in complex setups

-

Abrasion & weather-resistant

-

Non-toxic & heat-resistant rubber compound

-

Long service life in electrical environments

Standards (May Vary by Region)

-

IS: 7654

-

ASTM D2000 (for rubber material properties)

-

OEM-specific standards for furnace equipment

Want help selecting the right size, getting a sample spec sheet, or adding it to a purchase list or technical submittal?

Superior Safety for Power Applications

Designed with carbon-free, non-conductive materials, this hose ensures optimal insulation in high-risk environments like power generation stations and industrial sites. Its orange color improves visibility, helping to enhance workplace safety while protecting your electrical cables from heat, abrasion, and hazardous exposure.

Unmatched Durability and Performance

Offering excellent heat and weather resistance, our hose withstands both indoor and outdoor conditions with ease. The smooth surface finish and abrasion-resistant cover provide long-lasting performance, even under intensive operating environments, ensuring reliable protection for your critical systems.

Customizable Solutions for Diverse Needs

We cater to a wide range of industrial requirements, supplying hoses with various diameters, lengths, and connection types, including flanged, plain end, and threaded options. Dealers, fabricators, and manufacturers across India trust our expertise in supplying tailored hose solutions for unique applications.

FAQ's of Carbon Free Rubber Hose:

Q: How is the carbon free rubber hose used in electrical power plants and other industrial environments?

A: The carbon free rubber hose is primarily used for cooling and protecting power cables by providing excellent electrical insulation and heat resistance. Its non-conductive construction guarantees operational safety in power plants, steel mills, and glass factories where accidental electrical conduction must be avoided.Q: What makes this hose suitable for both indoor and outdoor installations?

A: This hose features outstanding temperature and weather resistance, maintaining performance from -40C to +100C. Its abrasion-resistant rubber cover and smooth finish allow it to withstand harsh outdoor elements as well as rigorous use in indoor setups.Q: When should I choose a carbon free hose over a standard rubber hose?

A: A carbon free hose is essential when working in environments where electrical insulation is critical, such as near live power cables. Unlike standard hoses, its non-conductive construction prevents accidental electrical transmission, protecting personnel and sensitive equipment.Q: Where can the carbon free rubber hose be installed, and what are the recommended environments?

A: It is engineered for installation in industrial settings, such as electrical substations, steel mills, and glass manufacturing units. The hose is suitable for both fixed and flexible setups, handling power cable cooling and other applications in varied environments.Q: What is the process for customizing the hose to specific requirements?

A: Clients can specify their needed hose length, diameter, and connection type (flanged, plain end, or threaded). Our manufacturing process accommodates custom requests to ensure a perfect fit for your operational needs, including specialized packing and reinforcement options.Q: What are the benefits of using a carbon free, electrically non-conductive hose?

A: This hose guarantees enhanced operator safety, excellent heat and weather resistance, and long-term durability. Its robust design helps prevent electrical accidents, reduces maintenance downtime, and extends the lifespan of both cable systems and the hose itself.Q: How do I ensure proper installation and maintenance of the carbon free hose?

A: Ensure the hose is selected based on correct dimensions, pressure rating, and connection type for your application. Regular inspection for wear and adherence to recommended bend radius (minimum 150 mm) will optimize performance and service longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

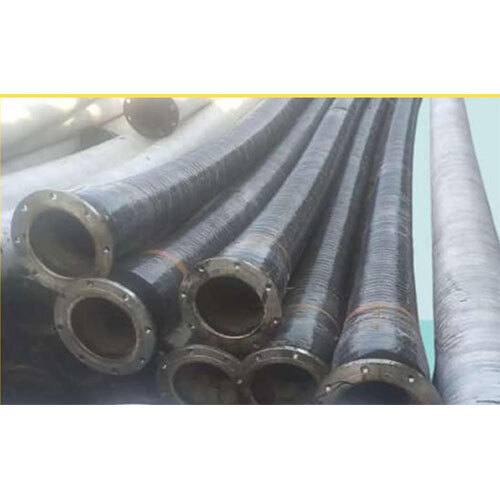

More Products in Industrial Rubber Hoses Category

Fly Ash Rubber Hose 5Mtr

Price 2400 INR / Meter

Minimum Order Quantity : 100

Material : Rubber

Shape : Round

Medium : Air

Hardness : 55 to 65 Shore A

Rubber Expansion Joint Bellow

Price 9000.0 INR

Minimum Order Quantity : 1

Material : Other, Highgrade synthetic rubber

Shape : Cylindrical with bellow convolution

Medium : Other, Water, oils, chemicals, mild acids, air

Hardness : 6070 Shore A

Industrial RRL Fire Hose Pipe 63mm Type A

Price 3200.0 INR

Minimum Order Quantity : 1

Material : Other, 100% Synthetic Yarn with Rubber Lining

Shape : Cylindrical (Hose Pipe)

Medium : Other, Water/Firefighting Foam

Hardness : Flexible/Woven Construction

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free