Vibrating Screen Rubber Beading

Price 220.0 INR/ Meter

Vibrating Screen Rubber Beading Specification

- Thickness

- 4mm Millimeter (mm)

- Inside Diameter

- 30 Millimeter (mm)

- Usage

- Vibrating screen rubber beadings are essential components for many types of vibrating screens, including: Mining & Minerals Processing: Screens that separate ores, stones and aggregates. Quarry & Aggregate Plants: Screening sand, gravel and crushed rock. Construction & Recycling: Separating material sizes on site. Industrial Sieving: Applications in chemical, food and pharmaceutical screening where vibration and containment are critical.

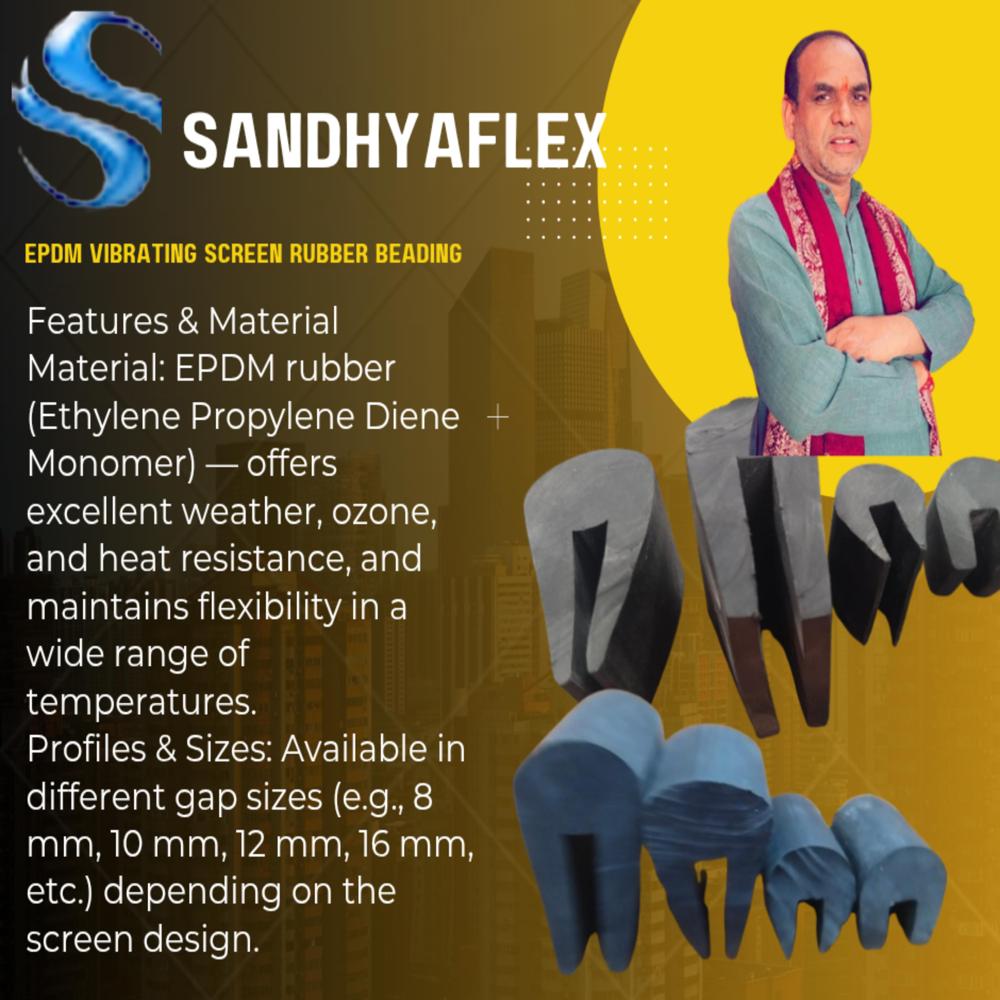

- Size

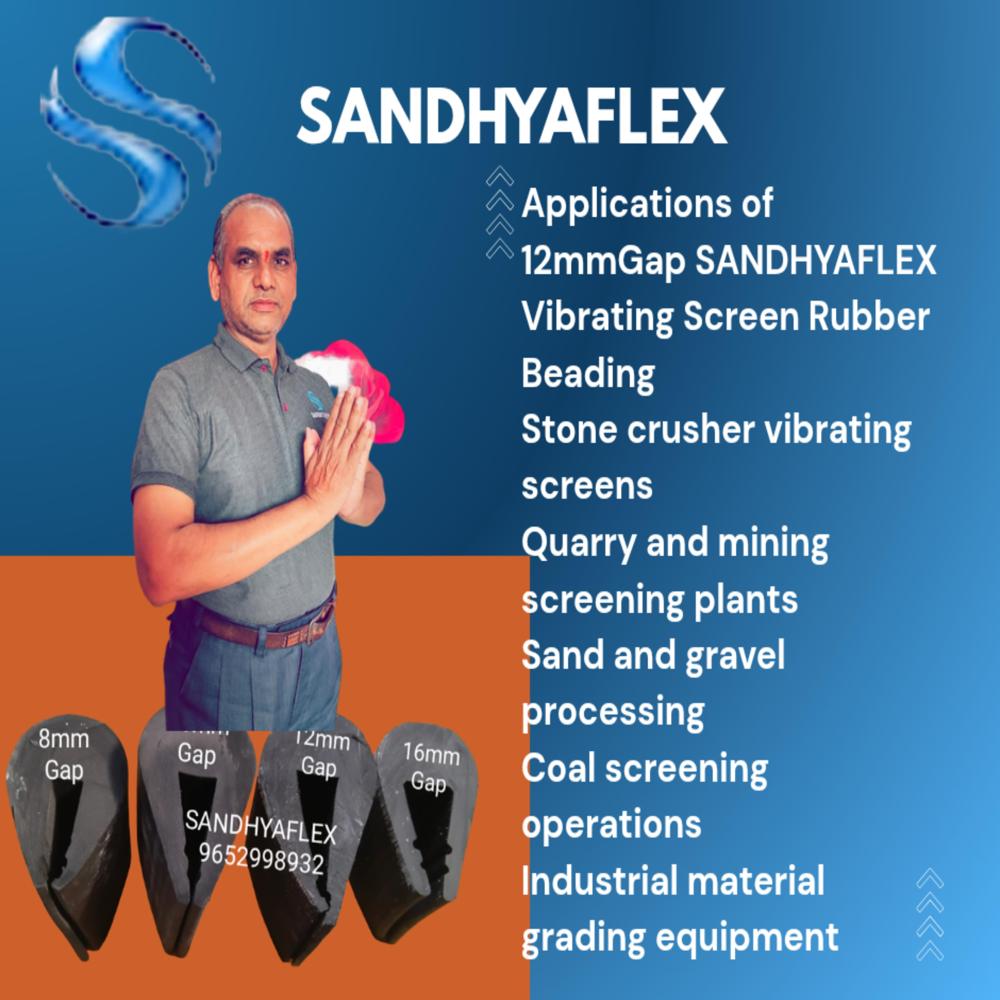

- 8mm ,10mm,12mm and 16mm Gap

- Material

- Other

- Height

- 50 Millimeter (mm)

- Structure

- Vibrating Screen Rubber Beadn

- Seals Type

- Rubber Beading

- Product Type

- Vibrating Screen Rubber Beadng

- Weight

- 46 Kilograms (kg)

- Bore Size

- 30mm

- Color

- Black

- Width

- 32 Millimeter (mm)

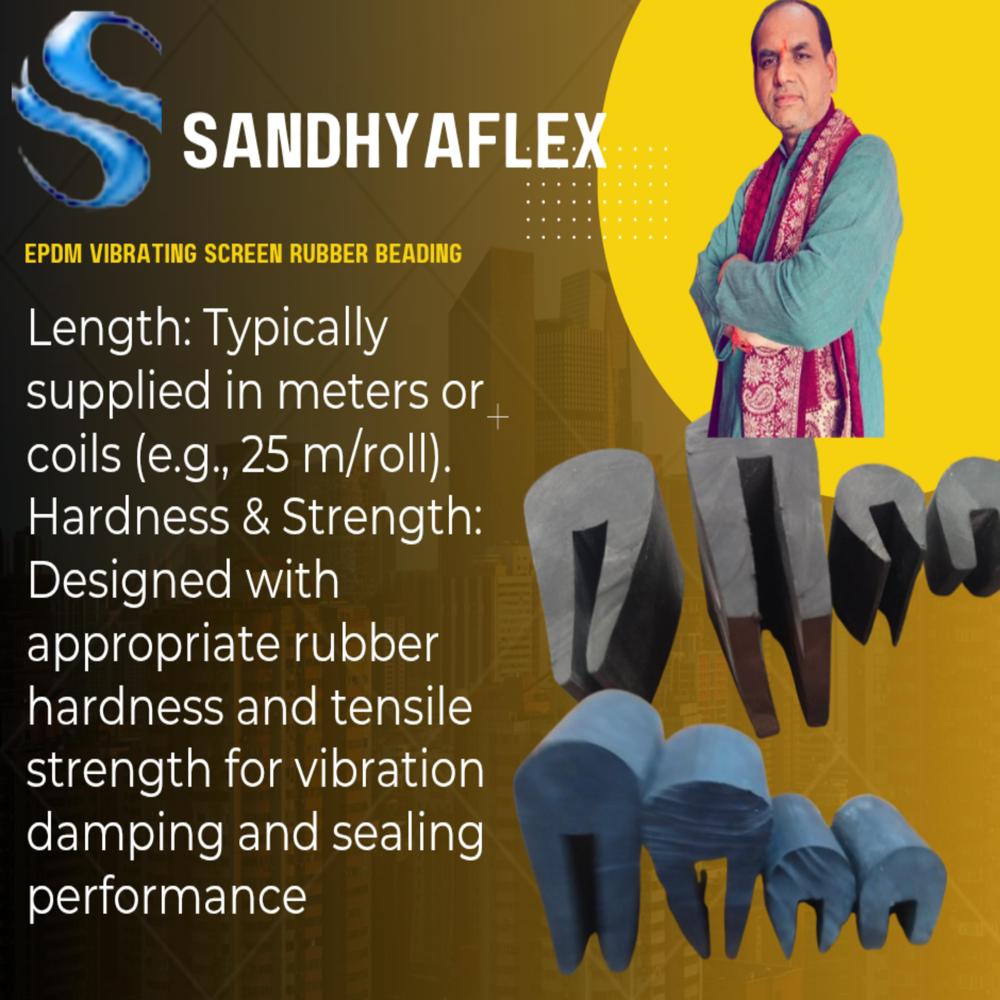

- Length

- 25 Meter (m)

- Outside Diameter

- 32 Millimeter (mm)

- Limiting Speed

- 20RPM RPM

- Load Capacity

- 250 Kilograms (kg)

- Warranty

- 6 Month

Vibrating Screen Rubber Beading Trade Information

- Minimum Order Quantity

- 1 Meter

- Delivery Time

- 7 Days

About Vibrating Screen Rubber Beading

Heres a clear overview of Sandhyaflex Vibrating Screen Rubber Beadings what they are, how they work, and why theyre used in industrial screening equipment

Sandhyaflex 12mm Gap Vibrating Screen Rubber Beading

210

Vibrating Screen Rubber Beading (Black)

120

Vibrating Screen Rubber Beading

160

Export Quality Vibrating Screen Rubber Beading

210

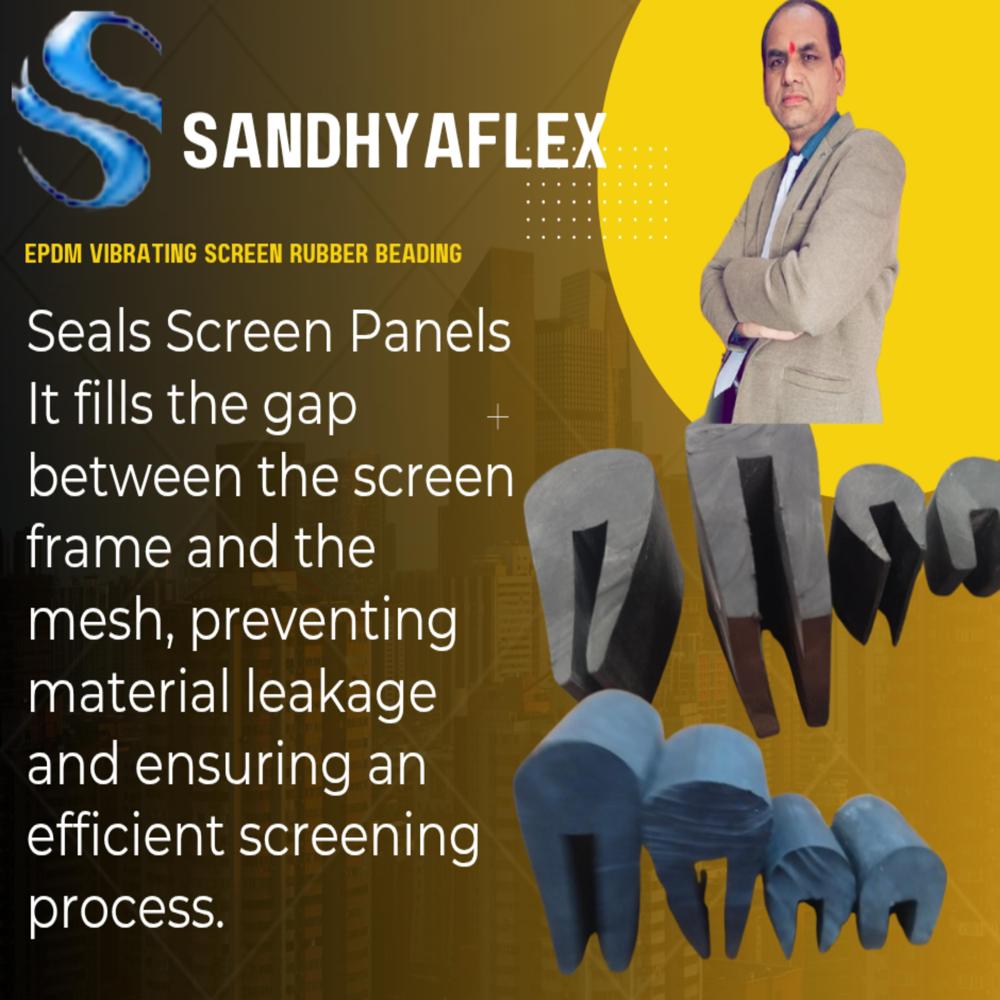

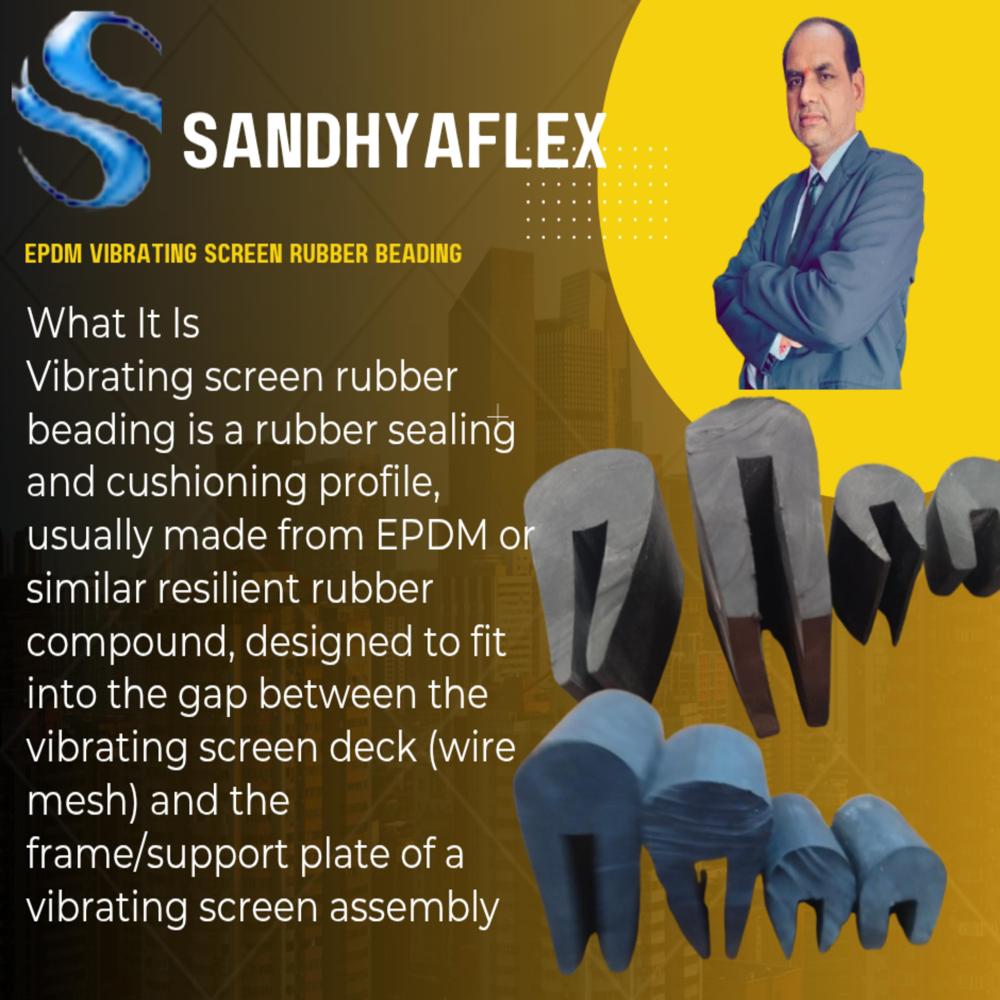

What They Are

Sandhyaflex Vibrating Screen Rubber Beadings are rubber sealing and cushioning strips designed to be fitted along the edges and support frames of vibrating screens used in mining, quarrying, aggregate processing, construction and other heavy industries. They are commonly manufactured from EPDM or natural rubber with high durability. (sandhyaenterprises.co.in)

Purpose & Function

Vibration Damping & Cushioning

These beadings act as a buffer between the vibrating screen deck and frame, absorbing vibration energy and reducing shock loads. This helps protect the screen mesh and support structure, extending equipment life. (sandhyaenterprises.co.in)

Sealing & Material Retention

They help seal the interface between the screen mesh and its frame, preventing material leakage and spillage during operation critical for maintaining screening efficiency. (sandhyaenterprises.co.in)

Noise & Wear Reduction

By absorbing vibration and preventing metal-to-metal contact, rubber beading reduces operational noise and minimizes wear on metal components. (sandhyaenterprises.co.in)

Key Features

-

Material: Typically EPDM or synthetic rubber flexible, strong and abrasion-resistant. (sandhyaenterprises.co.in)

-

Profiles & Sizes: Available for different gap sizes (e.g., 7 mm, 8 mm, 10 mm, 15 mm) to suit specific screen frame designs. (Sandhya Enterprises)

-

Temperature & Weather Resistance: Made to withstand heat, moisture and outdoor conditions. (sandhyaenterprises.co.in)

-

Easy Installation: Fits snugly on the support plate or screen frame, making replacement straightforward. (sandhyaenterprises.co.in)

Where Theyre Used

Vibrating screen rubber beadings are essential components for many types of vibrating screens, including:

-

Mining & Minerals Processing: Screens that separate ores, stones and aggregates. (Sandhya Enterprises)

-

Quarry & Aggregate Plants: Screening sand, gravel and crushed rock. (sandhyaenterprises.co.in)

-

Construction & Recycling: Separating material sizes on site. (sandhyaenterprises.co.in)

-

Industrial Sieving: Applications in chemical, food and pharmaceutical screening where vibration and containment are critical. (sandhyaenterprises.co.in)

Why They Matter

Longer Screen Life absorbs impact and vibration so metal parts last longer. (sandhyaenterprises.co.in)

Noise Reduction rubber dampens sound from high-frequency operation. (sandhyaenterprises.co.in)

Improved Efficiency seals edges to prevent leaks and maintain screening consistency. (sandhyaenterprises.co.in)

Lower Maintenance reduces damage to screens and frames, cutting downtime and replacement costs. (sandhyaenterprises.co.in)

Quick Tip: When choosing rubber beading, match the gap size and profile shape to your specific vibrating screen frame to ensure a tight seal and optimal vibration absorption. (Sandhya Enterprises)

Would you like installation guidance or help selecting the correct size/profile for your vibrating screen model?

Essential Protection for Vibrating Screens

Our vibrating screen rubber beading provides crucial sealing and cushioning for a variety of industrial screens. Used in mining, construction, and processing environments, the beading effectively absorbs vibrations and prevents mesh tearing. Its adaptable sizing ensures compatibility with a wide range of equipment, offering enhanced performance and extending screen life. This makes it a preferred choice for manufacturers, dealers, and fabricators across industrial sectors.

Versatile and Durable Design

Designed for rugged industrial use, the rubber beading features multiple gap sizes and a robust structure to fit different screen specifications. The black rubber material is not only durable but also resistant to wear, offering a reliable sealing solution in demanding applications. With a thickness of 4mm and a length of 25 meters per roll, it can be easily installed for simple maintenance and cost efficiency.

FAQ's of Vibrating Screen Rubber Beading:

Q: How is vibrating screen rubber beading installed on screens?

A: The rubber beading is fitted into the gap between the vibrating screen's mesh and frame. Choose the appropriate gap size (8mm, 10mm, 12mm, or 16mm) and press the beading into position to create a secure, cushioned seal. This process reduces vibration and prevents damage to the mesh and frame.Q: What materials can this rubber beading be used to screen?

A: This beading is suitable for screens processing ores, stones, sand, gravel, aggregates, and even materials in the chemical, food, and pharmaceutical industries. It is highly effective in both heavy industrial and sensitive sieving applications.Q: When should I replace vibrating screen rubber beading?

A: Inspect the rubber beading regularly-especially after six months or if you notice visible wear, cracking, or loss of elasticity. Prompt replacement helps maintain screen performance and prolongs overall equipment life.Q: Where is vibrating screen rubber beading commonly used?

A: It is widely used in India's mining and quarry operations, aggregate plants, construction sites, recycling facilities, and various industrial sieving processes that require effective vibration containment and mesh protection.Q: What are the main benefits of using this rubber beading?

A: The beading absorbs vibrations, protects both mesh and frame from abrasion, and provides a reliable seal to contain screened materials. This leads to reduced maintenance costs, improved screen longevity, and better operational safety.Q: Can I buy rubber beading directly from manufacturers or only from retailers?

A: You can purchase vibrating screen rubber beading from multiple sources in India, including manufacturers, dealers, suppliers, fabricators, producers, retailers, traders, and wholesalers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Rubber Beading Category

Vibrating Screen Rubber Beading

Price 220.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Vibrating Screen Rubber Beading

Outside Diameter : 32 Millimeter (mm)

Number Of Rows : Double Row

Bore Size : 30mm

12mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Solid Rectangular Beading

Outside Diameter : As per screen size (customizable)

Number Of Rows : Other, Single

Bore Size : 12mm Gap

16mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Rectangular Beading

Outside Diameter : Customisable as per Screen Frame

Number Of Rows : Single Row

Bore Size : 16mm Gap

10mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Rubber Beading for Vibrating Screens

Outside Diameter : Customized as per Screen Size

Number Of Rows : Other, Single

Bore Size : 10mm Gap

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free