Vibrating Screen Rubber Beading

Price 220.0 INR/ Meter

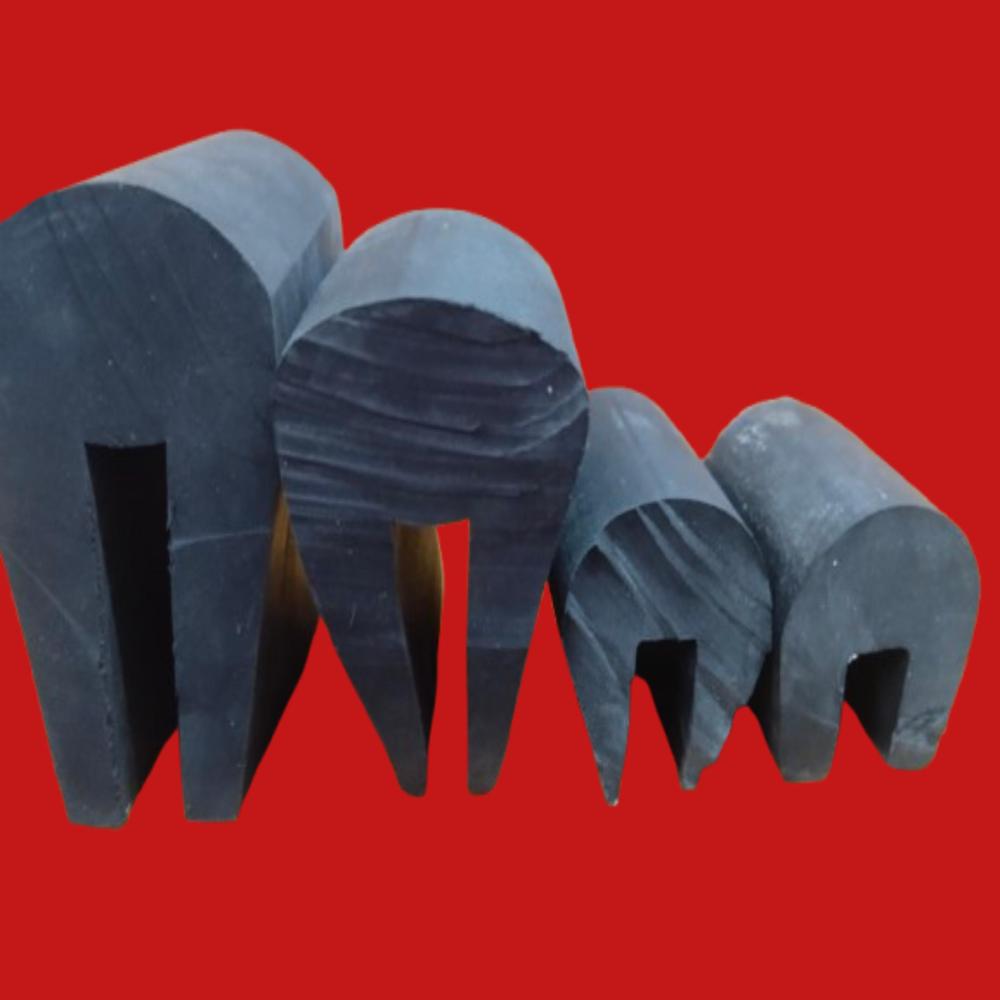

Vibrating Screen Rubber Beading Specification

- Inside Diameter

- 8mm Gap Millimeter (mm)

- Usage

- Where It s Used These rubber beadings are essential in many vibrating screen applications: Mining & Quarry Operations preventing material leakage and reducing wear. Aggregate & Mineral Processing improving screening efficiency. Cement & Coal Plants protecting mesh and frame from vibration damage. Industrial Screening Equipment for dust control and vibration control.

- Size

- Gap 8mm, Dia 32mm and Height 50mm

- Height

- 50 Millimeter (mm)

- Structure

- Vibrating Screen Rubber Beading

- Seals Type

- Vibrating Screen Rubber Beading

- Product Type

- EPDM Vibrating Screen Rubber Beading

- Number Of Rows

- Double Row

- Weight

- 1.84 Kilograms (kg)

- Color

- Rubber

- Bore Size

- 30mm

- Width

- 32 Millimeter (mm)

- Length

- 25 Meter (m)

- Outside Diameter

- 32 Millimeter (mm)

- Limiting Speed

- 25 RPM

- Load Capacity

- 250 Kilograms (kg)

- Warranty

- 6Month

Vibrating Screen Rubber Beading Trade Information

- Minimum Order Quantity

- 1 Meter

- Delivery Time

- 7 Days

About Vibrating Screen Rubber Beading

Heres a helpful summary of Sandhyaflex EPDM Vibrating Screen Rubber Beading a key component in industrial vibrating screens used for screening, separating and processing bulk materials:

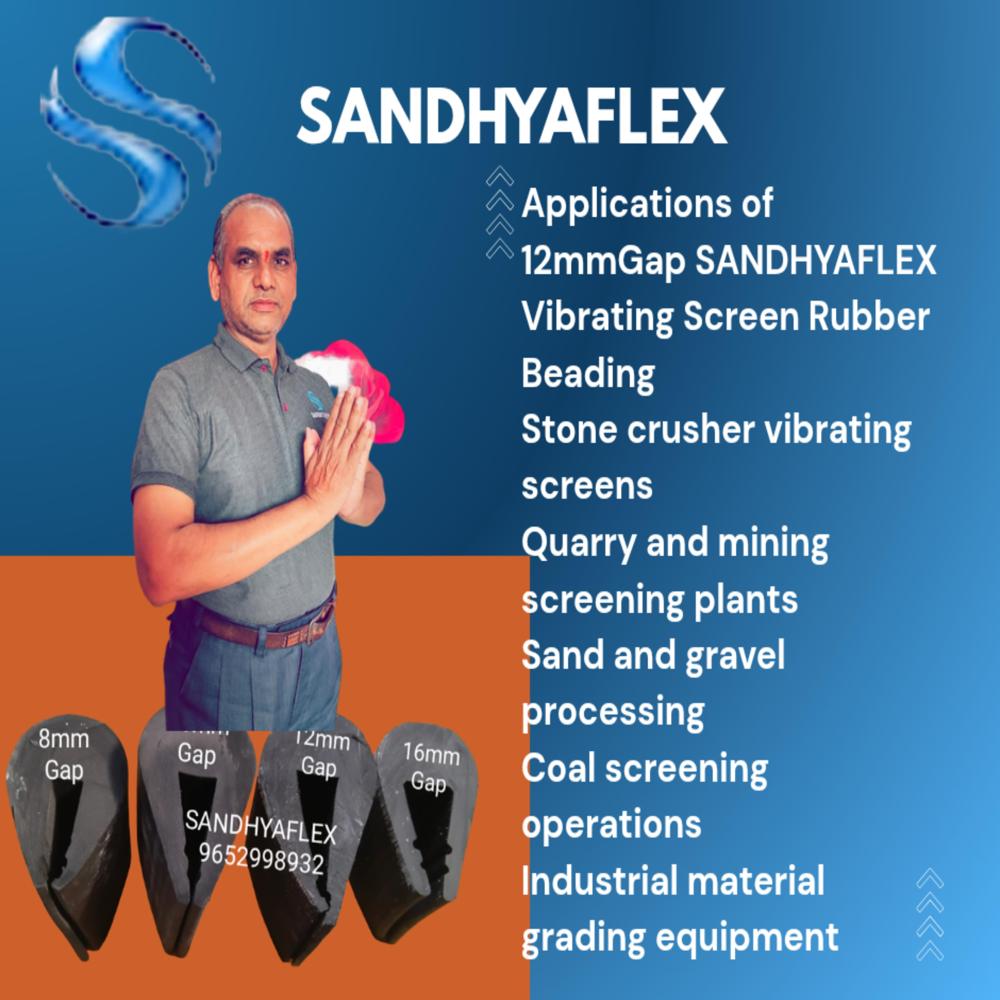

Sandhyaflex 12mm Gap Vibrating Screen Rubber Beading

210

Vibrating Screen Rubber Beading Black

120

Vibrating Screen Rubber Beading

160

Export Quality Vibrating Screen Rubber Beading

210

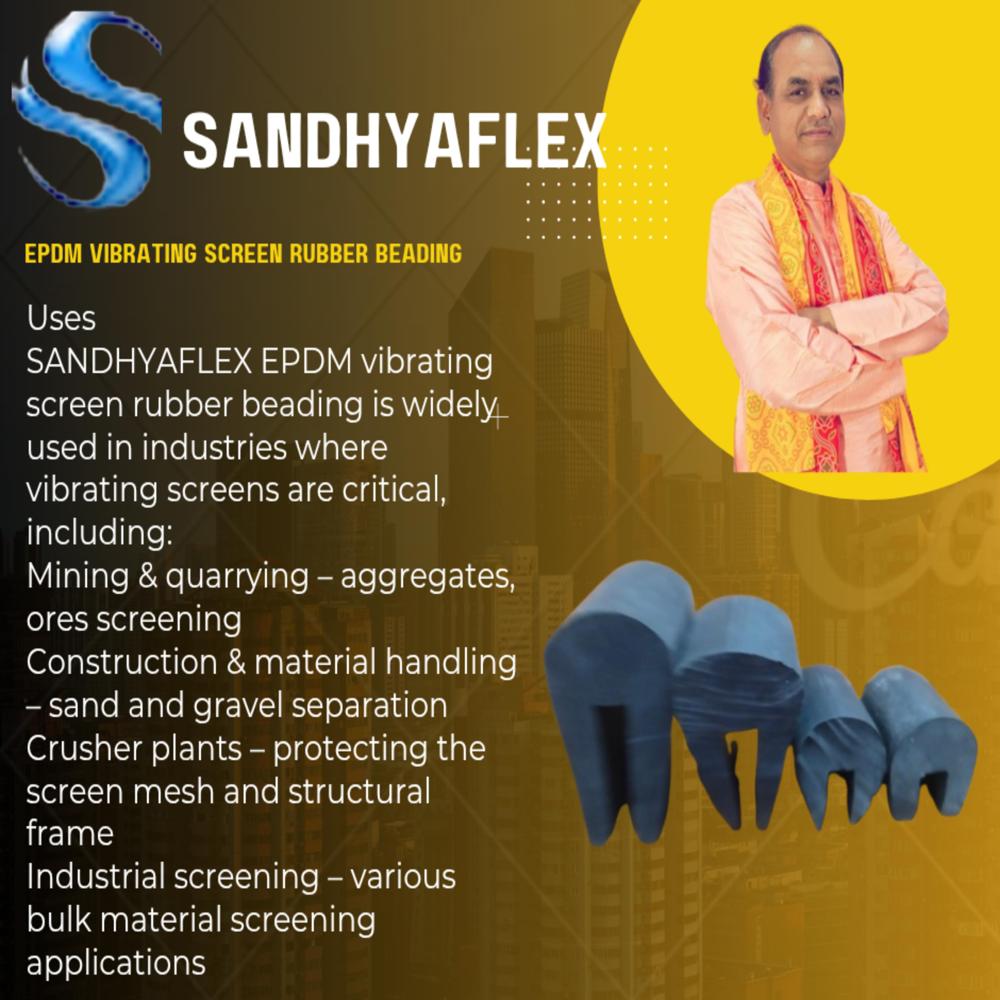

What It Is

Sandhyaflex 12mm Gap Vibrating Screen Rubber Beading and similar products like Vibrating Screen Rubber Beading Black, Vibrating Screen Rubber Beading and Export Quality Vibrating Screen Rubber Beading are rubber sealing and cushioning strips used mainly in vibrating screen assemblies in industries such as mining, quarrying, aggregates, cement plants and material processing. (sandhyaenterprises.co.in)

These beadings are frequently made from EPDM (Ethylen-Propylene-Diene Monomer) rubber or other durable rubber compounds that combine flexibility with high resistance to abrasion, weathering and vibration. (sandhyaenterprises.co.in)

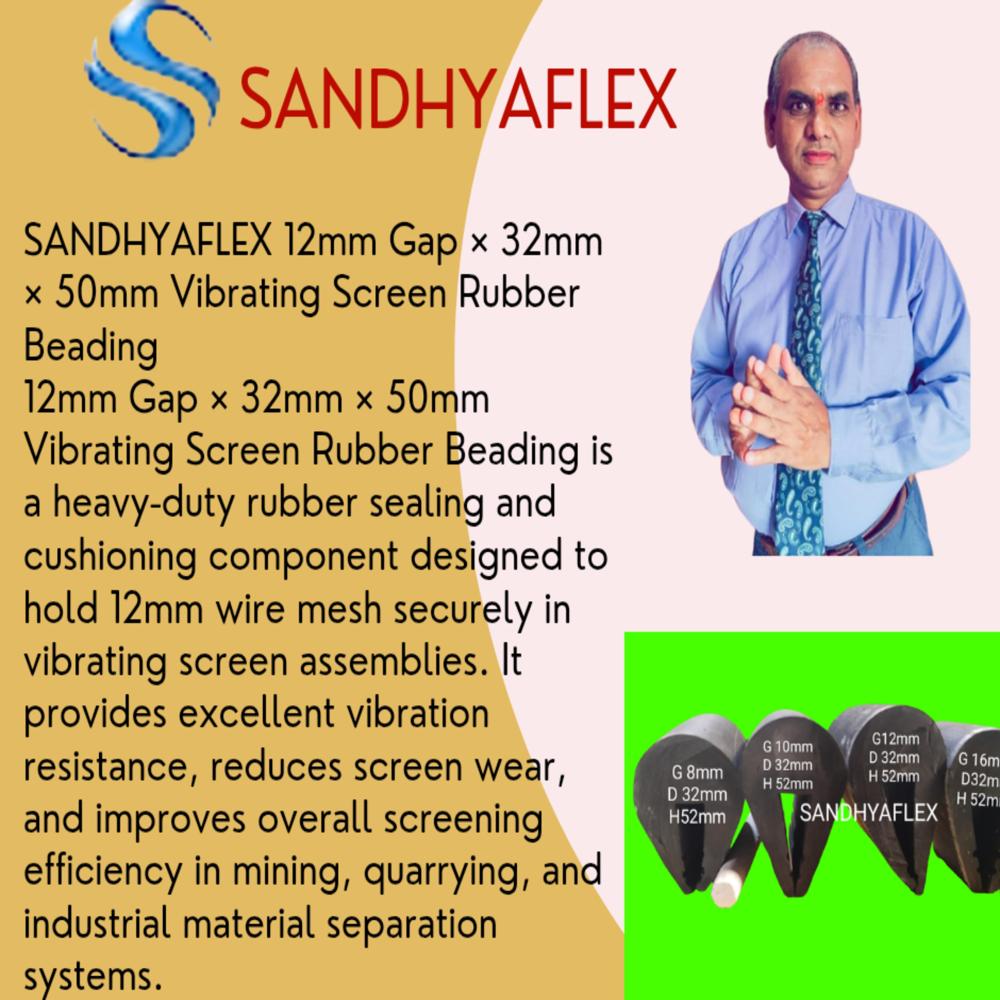

Key Features

1. Vibration Damping & Cushioning

Rubber beading absorbs vibrational energy produced during screen operation, protecting the screen mesh and frame from excessive stress and wear. (sandhyaenterprises.co.in)

2. Sealing & Material Retention

Installed between the screen deck and frame, the beading creates a tight seal to prevent material leakage or spillage during screening, improving screening performance and reducing waste. (sandhyaenterprises.co.in)

3. Noise Reduction

By absorbing vibrations and reducing metal-to-metal contact, rubber beading helps lower operational noise, which can be important in industrial environments. (sandhyaenterprises.co.in)

4. Abrasion & Weather Resistance

Made from high-quality EPDM or similar rubber, these beadings are resistant to abrasion, weather exposure, and UV, extending service life in tough conditions. (sandhyaenterprises.co.in)

5. Easy Installation & Replacement

Typically supplied in coils or lengths that can be pressed into gaps between the screen frame and mesh, they are simple to install or replace during maintenance, minimizing downtime. (sandhyaenterprises.co.in)

6. Custom Sizes & Profiles

Available for different gap sizes (e.g., 7 mm, 8 mm, 10 mm, 12 mm, 15 mm) and shapes to match specific vibrating screen designs. (sandhyaenterprises.co.in)

Where Its Used

These rubber beadings are essential in many vibrating screen applications:

-

Mining & Quarry Operations preventing material leakage and reducing wear. (sandhyaenterprises.co.in)

-

Aggregate & Mineral Processing improving screening efficiency. (sandhyaenterprises.co.in)

-

Cement & Coal Plants protecting mesh and frame from vibration damage. (sandhyaenterprises.co.in)

-

Industrial Screening Equipment for dust control and vibration control. (sandhyaenterprises.co.in)

Typical Benefits

Extends equipment life by reducing wear on screen mesh and support structures. (sandhyaenterprises.co.in)

Improves screening efficiency by maintaining tight mesh fit and preventing leaks. (sandhyaenterprises.co.in)

Reduces maintenance costs thanks to durability and easy replacement. (sandhyaenterprises.co.in)

Enhances safety and comfort by lowering vibration and noise. (sandhyaenterprises.co.in)

Quick Tip

When selecting Sandhyaflex EPDM rubber beading, choose the correct gap size and profile matching your vibrating screen frame (e.g., 10 mm, 12 mm) for optimal sealing and damping effectiveness. (sandhyaenterprises.co.in)

If you want, I can help you calculate how much beading length youll need based on your screen frame dimensions!

Reliable Protection for Vibrating Screens

The Vibrating Screen Rubber Beading acts as a vital buffer between the mesh and the frame of vibrating screens, significantly minimizing vibration-induced damage. This enhances the longevity of screening equipment and ensures stable, uninterrupted industrial operations, especially in rigorous environments like mining and mineral processing plants.

Versatile Use Across Key Industries

This rubber beading is engineered for use in mining, quarrying, aggregate handling, cement, and coal processing. Its robust structure ensures effective dust and material leakage control, contributing to safer, cleaner, and more efficient workspaces. It is also compatible with most industrial screening machines that demand high performance and reliability.

FAQ's of Vibrating Screen Rubber Beading:

Q: How does Vibrating Screen Rubber Beading protect screening equipment?

A: Vibrating Screen Rubber Beading acts as a cushioning seal between the mesh and frame, absorbing vibration and preventing direct contact. This helps avoid frame deformation, mesh damage, and reduces noise, resulting in extended equipment service life.Q: What is the typical usage of this rubber beading in industrial settings?

A: It is mainly used in vibrating screens across mining, quarry, aggregate, mineral processing, cement, and coal plants to prevent material leakage, control dust, reduce wear, and protect structural components from vibration damage.Q: Where can this rubber beading be installed?

A: The beading is installed along the edges of vibrating screens, where the mesh meets the supporting frame. It can be used in a variety of industrial screening machines thanks to its standardized dimensions and robust construction.Q: What are the key benefits of using double row rubber beading?

A: Double row construction enhances sealing efficiency, offers better vibration absorption, and provides sturdier protection, resulting in fewer maintenance requirements and improved screening efficiency.Q: How is the rubber beading supplied and who can purchase it?

A: The rubber beading comes in 25-meter rolls, ideal for dealers, fabricators, manufacturers, traders, wholesalers, and retailers in India seeking reliable screening solutions for various industrial applications.Q: What is the process for installing the Vibrating Screen Rubber Beading?

A: Installation involves measuring the screen perimeter, cutting the beading to length, and securely fitting it to the frame/mesh interface, ensuring a snug fit for optimal protection and vibration dampening.Q: What is the warranty period for this product?

A: This Vibrating Screen Rubber Beading is backed by a 6-month warranty, reflecting the manufacturer's confidence in its durability and performance in heavy-duty industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Rubber Beading Category

12mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Solid Rectangular Beading

Material : Other, High Tensile Rubber / EPDM Rubber

Thickness : 12mm

Number Of Rows : Other, Single

16mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Rectangular Beading

Material : Other, HighGrade EPDM Rubber

Thickness : 10mm (Approximate)

Number Of Rows : Single Row

10mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Rubber Beading for Vibrating Screens

Material : Other, Premium Quality Rubber

Thickness : Standard or Customized as Required

Number Of Rows : Other, Single

12mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Flat Rubber Beading, UProfile

Material : Other, Premium Grade Rubber (EPDM/Natural Rubber)

Thickness : Approximately 1015mm

Number Of Rows : Other, Single

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS