Vibrating Screen Rubber Beading

Price 130.0 INR/ Meter

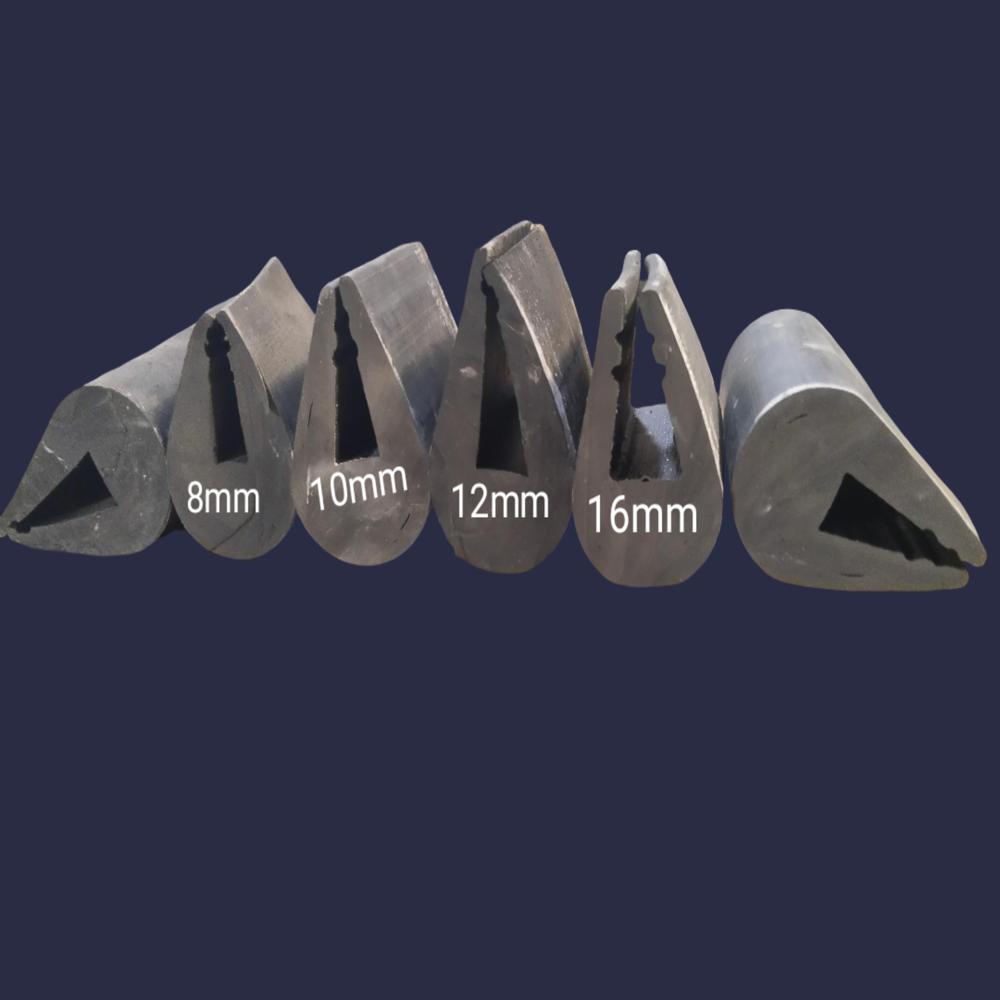

Vibrating Screen Rubber Beading Specification

- Thickness

- 10 mm to 25 mm (Standard), can be customized

- Material

- High-quality natural rubber / EPDM rubber

- Structure

- Flexible extruded rubber beading

- Number Of Rows

- Single

- Outside Diameter

- As per screen size (Customizable)

- Packaging Type

- Roll, bundle, or cut pieces

- Hardness

- 60 Shore A ±5

- Temperature Resistance

- -30°C to +80°C

- Tensile Strength

- 8 MPa minimum

- Feature

- Anti-vibration, excellent weathering, and abrasion resistance

- Installation

- Easy to install, fits precisely onto screen periphery

- Color

- Black (Standard), other colors on request

- Length

- Up to 50 meters roll or cut lengths as required

- Finish

- Smooth surface, free from blisters

- Application

- Specifically designed for vibrating screens, used as a clamp to avoid metal-to-metal contact

About Vibrating Screen Rubber Beading

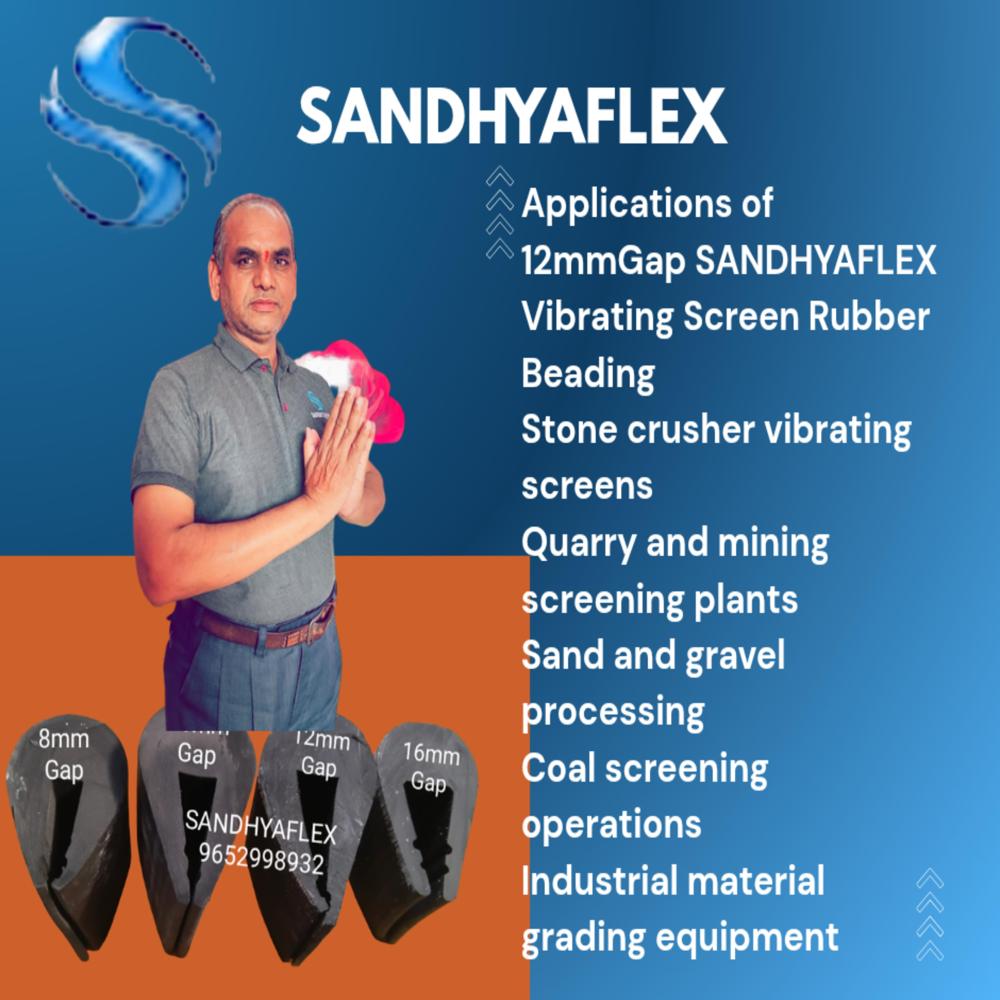

Versatile Application and Use Environments

Vibrating Screen Rubber Beading is extensively used in mining, quarrying, and material processing facilities. It is specially crafted for vibrating screens, acting as a clamp to eliminate metal contact and enhance operational life. Suitable for both dry and wet application media, this product's use type ranges from heavy-duty industrial contexts to moderate screening systems. Its flexible, single-row structure ensures compatibility and efficiency in all types of vibrating screen setups.

Certifications, Sampling, and Main Domestic Market

Our Vibrating Screen Rubber Beading is handed over only after thorough quality checks and compliance with industry certifications. Sample policies are tailored for businesses wishing to assess product quality prior to a larger outlay or official purchase order. With a robust presence in the main domestic market across India, we ensure prompt delivery and reliable supply to manufacturers, traders, and retailers nationwide, reinforcing long-term business relationships through consistent product excellence.

FAQ's of Vibrating Screen Rubber Beading:

Q: How is Vibrating Screen Rubber Beading installed on vibrating screens?

A: The rubber beading is designed for easy installation. It fits precisely onto the screen periphery and can be secured as a clamp to prevent metal-to-metal contact, ensuring quick and efficient setup.Q: What benefits does this beading provide for vibrating screen applications?

A: It offers remarkable anti-vibration protection, excellent weather and abrasion resistance, and extends the screen's operational lifespan by preventing damage caused by direct metal contact.Q: Where can Vibrating Screen Rubber Beading be used?

A: This product is ideal for use in mining, quarrying, mineral processing, and other environments employing vibrating screens. It is suitable for both wet and dry material processing applications.Q: What is the process for ordering custom sizes and packs?

A: You can request custom lengths, thicknesses, outside diameters, and colors by specifying your screen's requirements when placing your purchase order. The product is available in rolls, bundles, or cut pieces to suit diverse needs.Q: When should businesses consider replacing their existing rubber beading?

A: Replacement is advised when the existing rubber beading shows signs of excessive wear, loss of flexibility, cracking, or if its anti-vibration performance has notably decreased.Q: What certifications and sampling policies are available for quality assurance?

A: Certifications are provided upon request, affirming compliance with industry standards. Samples can be handed over to interested clients to evaluate the product before committing to a full-scale outlay.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Rubber Beading Category

Vibrating Screen Rubber Beading

Price 220.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Vibrating Screen Rubber Beading

Inside Diameter : 8mm Gap Millimeter (mm)

Load Capacity : 250 Kilograms (kg)

12mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Solid Rectangular Beading

Inside Diameter : 12mm Gap

Material : Other, High Tensile Rubber / EPDM Rubber

Load Capacity : Designed for Vibrating Screen Panel Support

16mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Rectangular Beading

Inside Diameter : 16mm Gap Suitable

Material : Other, HighGrade EPDM Rubber

Load Capacity : Supports Screen Tension

10mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Structure : Rubber Beading for Vibrating Screens

Inside Diameter : Designed for 10mm gap

Material : Other, Premium Quality Rubber

Load Capacity : Suitable for screen vibration loads

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free