Vibrating Screen Rubber Beading

Price 130.0 INR/ Meter

Vibrating Screen Rubber Beading Specification

- Thickness

- 10 mm to 30 mm (customizable)

- Material

- EPDM Rubber / Natural Rubber / Synthetic Rubber

- Structure

- Flexible beading strip

- Installation

- Easy to fit on screen panels

- Weather Resistance

- Excellent

- Temperature Range

- -20°C to +80°C

- Packaging Type

- Rolls or Coils

- Color

- Black / As per requirement

- Application

- Vibrating screens, preventing vibration damage

- Finish

- Fine, smooth surface

- Tensile Strength

- High resilience

- Hardness

- 60-70 Shore A

- Length

- 10 m, 12 m, or customized

About Vibrating Screen Rubber Beading

Heres a detailed overview of Vibrating Screen Rubber Beading, commonly used in mining, aggregate, and industrial applications for ensuring tight seals and vibration resistance in vibrating screens.

Vibrating Screen Rubber Beading

Product Description:

Vibrating Screen Rubber Beading is a flexible, durable rubber profile used to provide a seal between the screen and the frame. It is designed to withstand vibration, abrasion, and wear from the materials being screened. The rubber beading helps retain material within the screen, prevent leakage, and enhance performance by improving sealing efficiency.

Key Features:

-

Durable and Flexible: Designed to endure the constant vibrations of vibrating screens.

-

Abrasion-Resistant: Can withstand wear from sand, gravel, or other coarse materials.

-

Weather & Ozone-Resistant: Suitable for outdoor applications where exposure to UV and weather is common.

-

Easy to Install: Typically available in rolls or custom lengths and can be cut to fit different screen sizes.

-

Custom Profiles: Available in a wide range of shapes and sizes to match the specific needs of the vibrating screen frame and screen mesh.

Typical Specifications:

| Specification | Details |

|---|---|

| Material | Natural rubber, EPDM, or SBR (styrene-butadiene rubber) |

| Shape | Bead, strip, or U-profile (custom shapes available) |

| Thickness | 5 mm to 20 mm |

| Width | 10 mm to 50 mm (custom sizes available) |

| Temperature Range | -20C to +80C |

| Color | Black or custom colors (typically black for UV resistance) |

| Hardness | 60-70 Shore A (for flexibility and durability) |

| Length | Custom lengths or standard rolls (up to 50 m) |

Applications:

-

Vibrating Screens: Used to form seals between the screen mesh and screen frame to prevent material from spilling out.

-

Mining & Quarrying: Often used in aggregate screening plants to separate different sizes of materials.

-

Construction: For use in gravel and sand screening systems.

-

Recycling Plants: Ensures fine materials like plastic, glass, or metal are properly separated.

-

Industrial Sieving Machines: Used in various industries for separating and grading materials.

Benefits:

-

Improved Material Retention: Prevents material from escaping through the sides of the screen.

-

Increased Efficiency: Enhances the vibration process and the separation of materials by maintaining tight seals.

-

Reduced Downtime: Resistant to wear, reducing the frequency of replacements.

-

Cost-Effective: Helps extend the life of the vibrating screen and reduces maintenance costs.

-

Noise Reduction: Dampens noise from vibrating equipment, contributing to a quieter working environment.

Customization Options:

-

Custom Shapes: Available in various cross-sectional shapes (flat, round, U-profile, etc.) to meet design specifications.

-

Special Compounds: For higher abrasion resistance or extreme temperature tolerance (such as heat-resistant or oil-resistant versions).

-

Color Customization: For identification purposes or aesthetics (typically black or green for industrial use).

Installation:

-

Easy Installation: Can be glued, taped, or mechanically attached to the vibrating screen frame.

-

Long-lasting Seal: Ensures no material escapes through gaps, improving screening efficiency.

-

Minimal Maintenance: Designed to last longer than standard seals, reducing the need for frequent replacements.

Would you like:

-

A datasheet or installation guide for this product?

-

Help sourcing suppliers or manufacturers of vibrating screen rubber beading?

-

Assistance calculating material quantities for a specific project?

Let me know how I can assist!

Key Features and Material Advantages

Vibrating Screen Rubber Beading utilizes EPDM, natural, or synthetic rubber, offering flexibility, smooth finishes, and customizable thickness (10 mm to 30 mm). Its high tensile strength and resilience allow it to withstand tough screening environments and frequent vibrations. Available in black or colors as per requirements, its weather resistance ensures longevity, even under harsh environmental conditions.

Versatile Applications and Easy Installation

This beading is widely used in vibrating screens across various industries to prevent vibration-induced damage. Designed for quick and hassle-free fitting on screen panels, it streamlines maintenance processes and minimizes downtime. Fabricators, suppliers, and manufacturers across India supply these beading strips in convenient coil or roll packaging for bulk and retail needs.

Durable Performance in Extreme Conditions

With an operational temperature range spanning from -20C to +80C, Vibrating Screen Rubber Beading performs reliably in both cold and hot environments. Its fine, smooth surface and robust construction safeguard vibrating screens, contributing to reduced maintenance costs and enhanced service life of screening equipment.

FAQ's of Vibrating Screen Rubber Beading:

Q: How is Vibrating Screen Rubber Beading installed on screen panels?

A: Rubber beading is designed for easy installation and fits directly onto the edges of vibrating screen panels. Its flexible structure allows quick adjustment to different panel sizes, streamlining the fitting process whether performed by dealers, fabricators, or maintenance teams.Q: What are the main applications of vibrating screen rubber beading?

A: The primary application is in vibrating screens to prevent vibration damage and enhance the longevity of screen panels. Commonly used in mining, quarrying, and various industrial screening setups, it offers protection and stability in high-vibration environments.Q: When should vibrating screen rubber beading be replaced?

A: Replacement is recommended if the beading shows signs of wear, cracking, or loss of resilience, or during major screen maintenance. Routine inspections help identify when the material no longer effectively prevents damage or seals screen panels.Q: Where can I source vibrating screen rubber beading in India?

A: Vibrating screen rubber beading is widely available in India through dealers, manufacturers, suppliers, traders, retailers, wholesalers, and fabricators who offer customized options and bulk or retail packaging as required.Q: What types of rubber materials are used in these beading strips?

A: The beading strips are manufactured using EPDM rubber, natural rubber, or synthetic rubber. These materials are selected for their flexibility, weather resistance, tensile strength, and ability to withstand a wide temperature range.Q: Why is using rubber beading beneficial for vibrating screens?

A: Rubber beading protects screens from vibration-induced damage, increases the lifespan of screen panels, and reduces maintenance costs. Its weather resistance and high resilience ensure reliable performance in demanding operational settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Rubber Beading Category

Vibrating Screen Rubber Beading

Price 220.0 INR / Meter

Minimum Order Quantity : 1 Meter

Number Of Rows : Double Row

Outside Diameter : 32 Millimeter (mm)

Structure : Vibrating Screen Rubber Beading

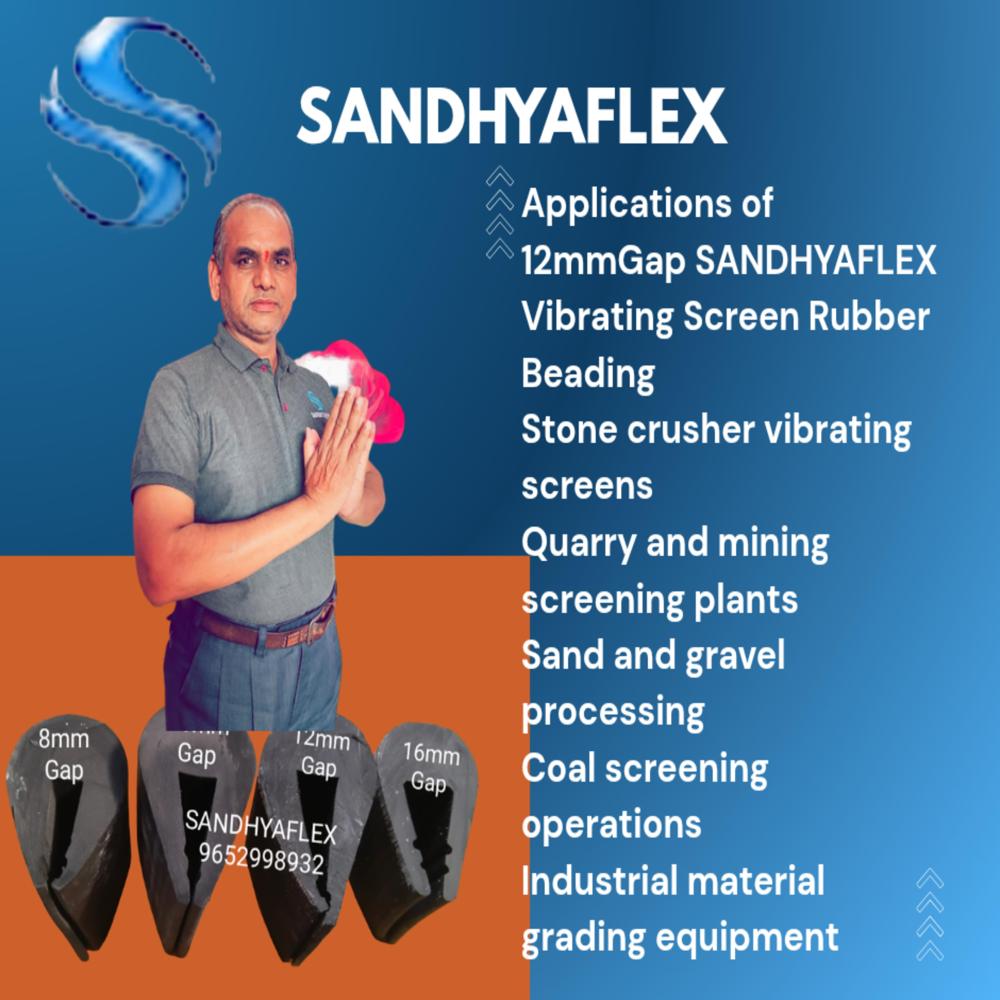

12mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Number Of Rows : Other, Single

Outside Diameter : As per screen size (customizable)

Structure : Solid Rectangular Beading

Material : Other, High Tensile Rubber / EPDM Rubber

16mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Number Of Rows : Single Row

Outside Diameter : Customisable as per Screen Frame

Structure : Rectangular Beading

Material : Other, HighGrade EPDM Rubber

10mm Gap Vibrating Screen Rubber Beading

Price 130.0 INR / Meter

Minimum Order Quantity : 1 Meter

Number Of Rows : Other, Single

Outside Diameter : Customized as per Screen Size

Structure : Rubber Beading for Vibrating Screens

Material : Other, Premium Quality Rubber

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS