Tarfelt sheet

Price 3000 INR/ Roll

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

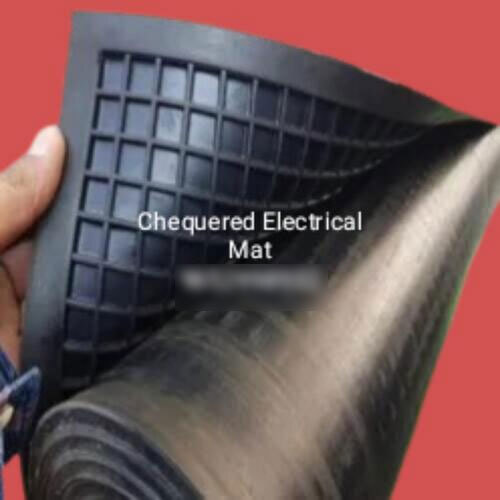

Checkered Rubber Sheet

Price 540.0 INR / Number

Minimum Order Quantity : 100

Size : Custom sizes available

Usage & Applications : Flooring, walkways, stair treads, industrial work areas, antislip covering

Material : Rubber (Natural/Synthetic Blend)

Color : Black

5mmx1mtrx 2Mtr Plain Rubber Sheet

Price 55.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Size : 5mmx1mtrx2Mtr

Usage & Applications : Gaskets, Packing, Flooring, Shock Absorption, Industrial Sealing, Insulation, AntiVibration

Material : Natural and Synthetic Rubber Blend

Color : Black

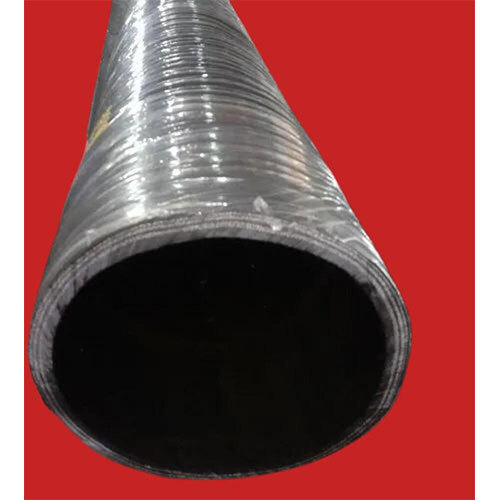

Rubber hose

Price 1125.0 INR / Number

Minimum Order Quantity : 1 Number

Size : 1/2 inch to 4 inch (custom sizes available)

Usage & Applications : Industrial fluid transfer, hydraulic and pneumatic systems, water and air delivery, chemical transport

Material : Natural Rubber/SBR/NBR/EPDM (as per specification)

Color : Black

Slurry Rubber Hose

Price 3500.0 INR / Meter

Minimum Order Quantity : 6

Size : Standard

Usage & Applications : Industrial

Material : Rubber

Color : Black

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS