Steel Laminated Elastomeric Bridge Bearing

Price 7000.0 INR/ Number

Steel Laminated Elastomeric Bridge Bearing Specification

- Precision Rating

- IS:3400, IRC:83 (Part-II) Standards

- Thickness

- 12 mm to 150 mm

- Lubrication Type

- Maintenance-Free (No Lubrication Required)

- Bearing Type

- Bridge Bearing

- Material

- Steel Plates and Neoprene Rubber

- Structure

- Steel Laminated Elastomeric

- Seals Type

- Integral to elastomer

- Number Of Rows

- Single

- Bore Size

- Custom as per design

- Outside Diameter

- Variable (as per drawing/specification)

- Load Capacity

- Up to 1000 Tonnes or as required

- Installation Location

- Between Bridge Deck and Substructure

- Applicable Bridge Types

- Highway, Railway, Flyovers, and Elevated Corridors

- Finish

- Anti-corrosive Coating on Steel Plates

- Hardness (Shore A)

- 60 ± 5

- Working Temperature Range

- -40°C to +70°C

- Compression Set

- As per IS/IRC requirements

- Shear Modulus

- 0.9-1.2 N/mm² (for Neoprene Rubber)

- Displacement Accommodation

- Horizontal and Rotational Movement Compensation

- Shape

- Rectangular or Circular as per project requirement

About Steel Laminated Elastomeric Bridge Bearing

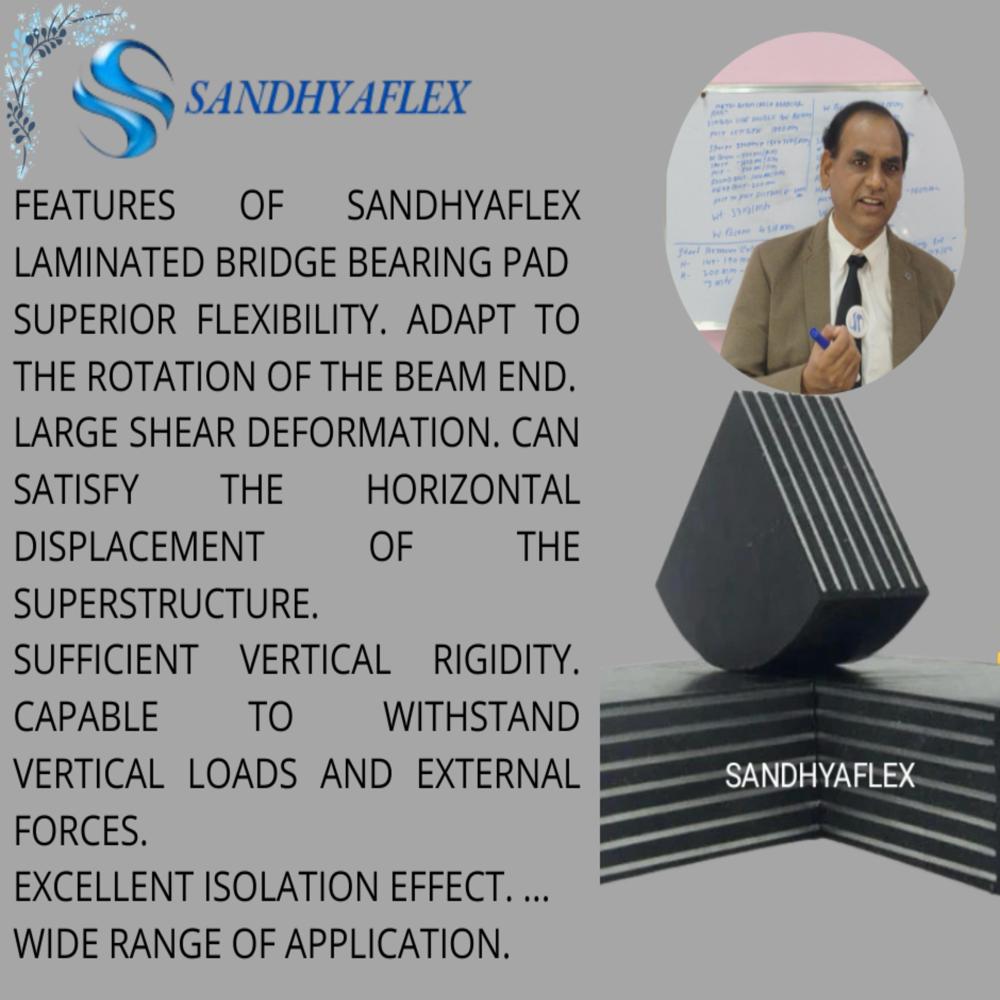

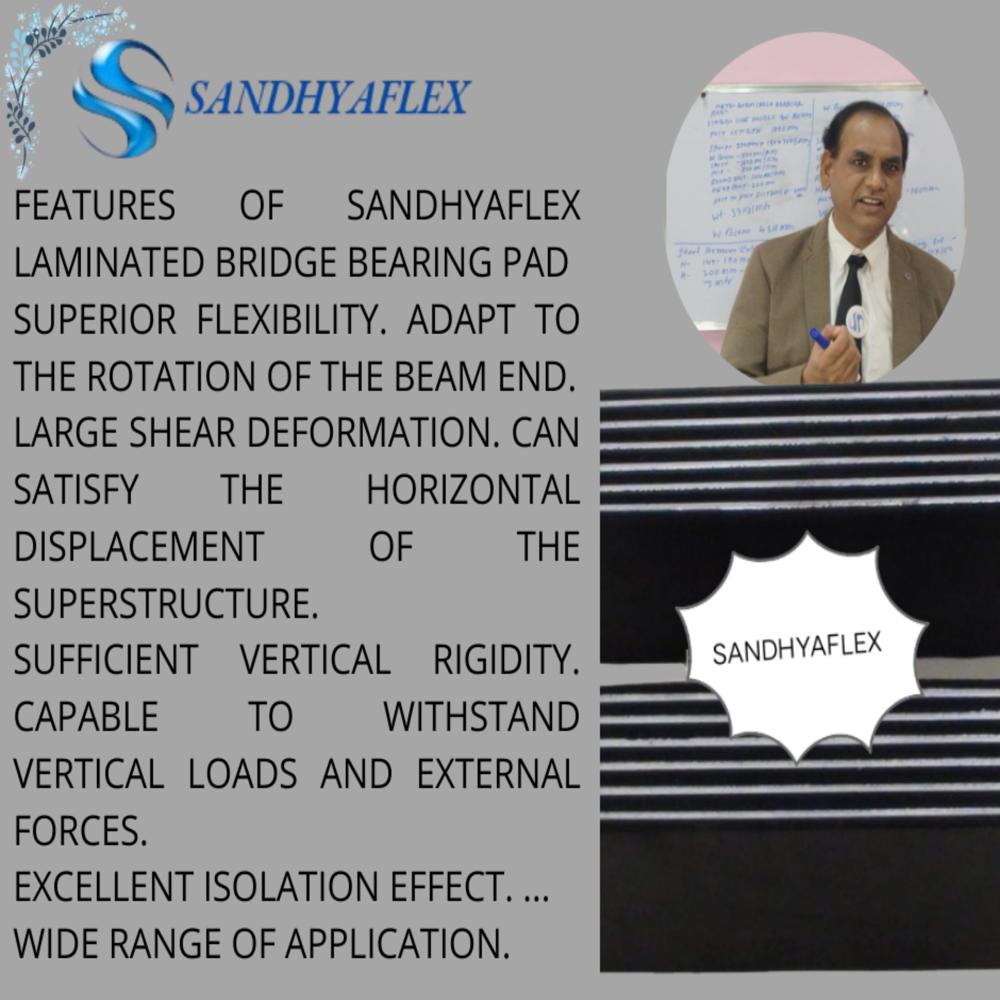

Applications and Installation Surface

Steel Laminated Elastomeric Bridge Bearings are perfectly suited for a variety of plant and infrastructure applications, especially on the critical interface between bridge decks and substructures. Their robust design ensures exceptional performance on highways, railways, flyovers, and elevated corridors. Used for compensating both horizontal and rotational bridge deck movements, these bearings ensure prolonged operational excellence. Their corrosion-resistant surface and integral seals make them ideal for long-term use in diverse environmental conditions.

Export Markets and Delivery Logistics

Our Steel Laminated Elastomeric Bridge Bearings are shipped with meticulous packing & dispatch processes to ensure safe transit to main export markets, including Asia, Africa, and the Middle East. Each unit is securely packaged according to international standards and shipped FOB from leading Indian ports. Typical delivery times are tailored to each order, ensuring reliability and efficiency. Trust our dedicated team for prompt dispatch and careful handling, delivering formidable value wherever your project may be.

FAQ's of Steel Laminated Elastomeric Bridge Bearing:

Q: How does the Steel Laminated Elastomeric Bridge Bearing accommodate movement in bridges?

A: The bearing is specifically engineered to accommodate horizontal and rotational movements, ensuring smooth expansion and contraction of the bridge deck, thus reducing structural stresses and prolonging bridge lifespan.Q: What are the main benefits of using anti-corrosive coatings on these bearings?

A: Anti-corrosive coatings protect the steel plates from harsh environmental conditions, significantly increasing the durability of the bearing and reducing maintenance requirements over time.Q: When should these bearings be installed during bridge construction?

A: Steel Laminated Elastomeric Bridge Bearings should be installed between the bridge deck and substructure, typically after assembling the substructure but before completing the superstructure, ensuring optimal load distribution and operational effectiveness.Q: Where are these bearings most commonly used?

A: These bearings are most commonly used in highway, railway, flyover, and elevated corridor constructions, anywhere bridges require reliable load transfer and movement accommodation.Q: What is the process for customizing the bearing design?

A: Customers can specify requirements such as shape, bore size, thickness, and load capacity, and the manufacturer will produce bearings tailored to exact project specifications, ensuring compliance with IS:3400 and IRC:83 standards.Q: How does the maintenance-free design benefit bridge operators?

A: The maintenance-free design eliminates the need for lubrication and routine servicing, saving time and reducing operational costs for bridge operators while maintaining top performance for years.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elastomeric Bridge Bearing Category

Mounting with Stud

Price 370.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Alloy Steel

Thickness : 12 mm

Bore Size : M8

Bearing Type : Other, Stud Type Track Roller

P Series Pad

Price 250.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Sintered Bronze / Steel / Customized

Thickness : Standard / Custom

Bore Size : Customizable (as per requirement)

Bearing Type : Other, P Series Pad

Mounting with Stud

Price 370.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Chrome Steel (SUJ2)

Thickness : 7 mm

Bore Size : M6 (Stud Thread Size)

Bearing Type : Other, Stud Type Track Roller

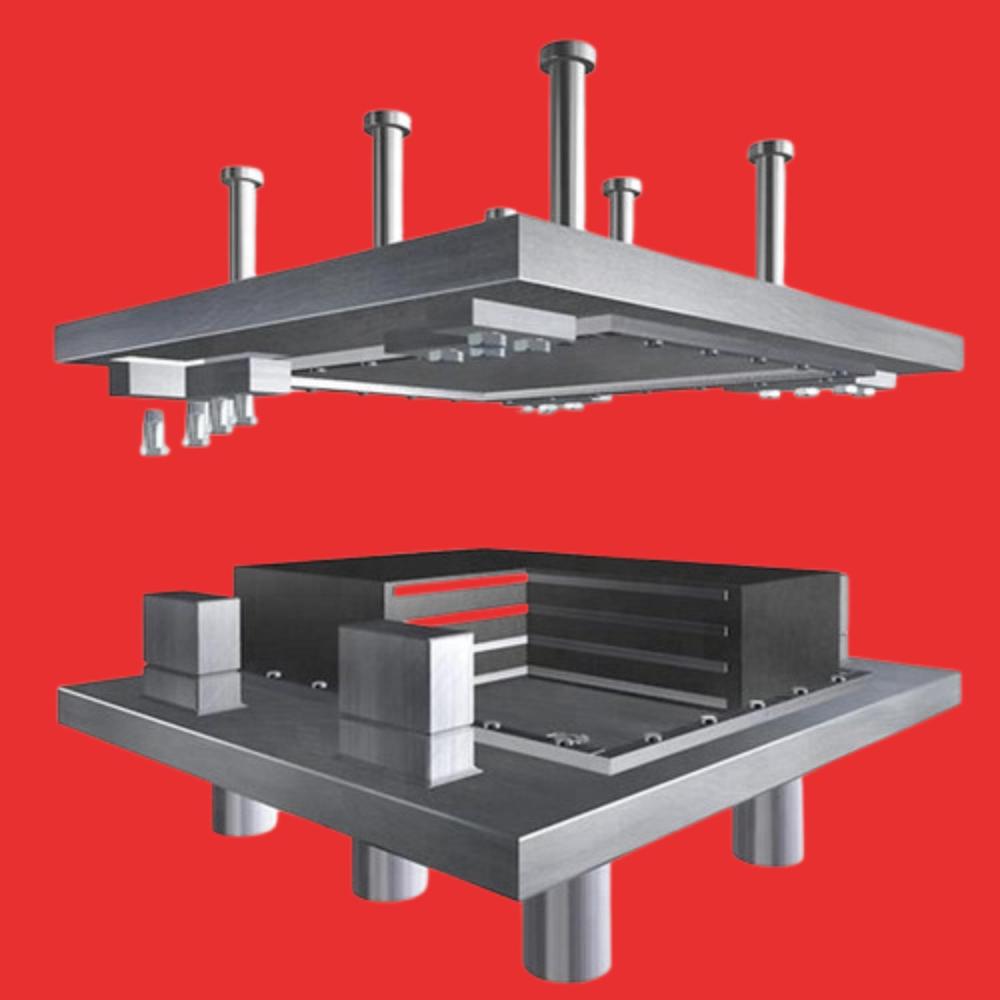

Ealstomeric Bride Bearing with Top and Bottom Steel Plate

Price 15000.0 INR / Number

Minimum Order Quantity : 1 Number

Material : Other, Natural Rubber/Neoprene with Mild Steel Plates

Thickness : 20 mm to 100 mm standard or per design

Bore Size : N/A (Noncylindrical product)

Bearing Type : Other, Elastomeric Bridge Bearing with Top & Bottom Steel Plate

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free