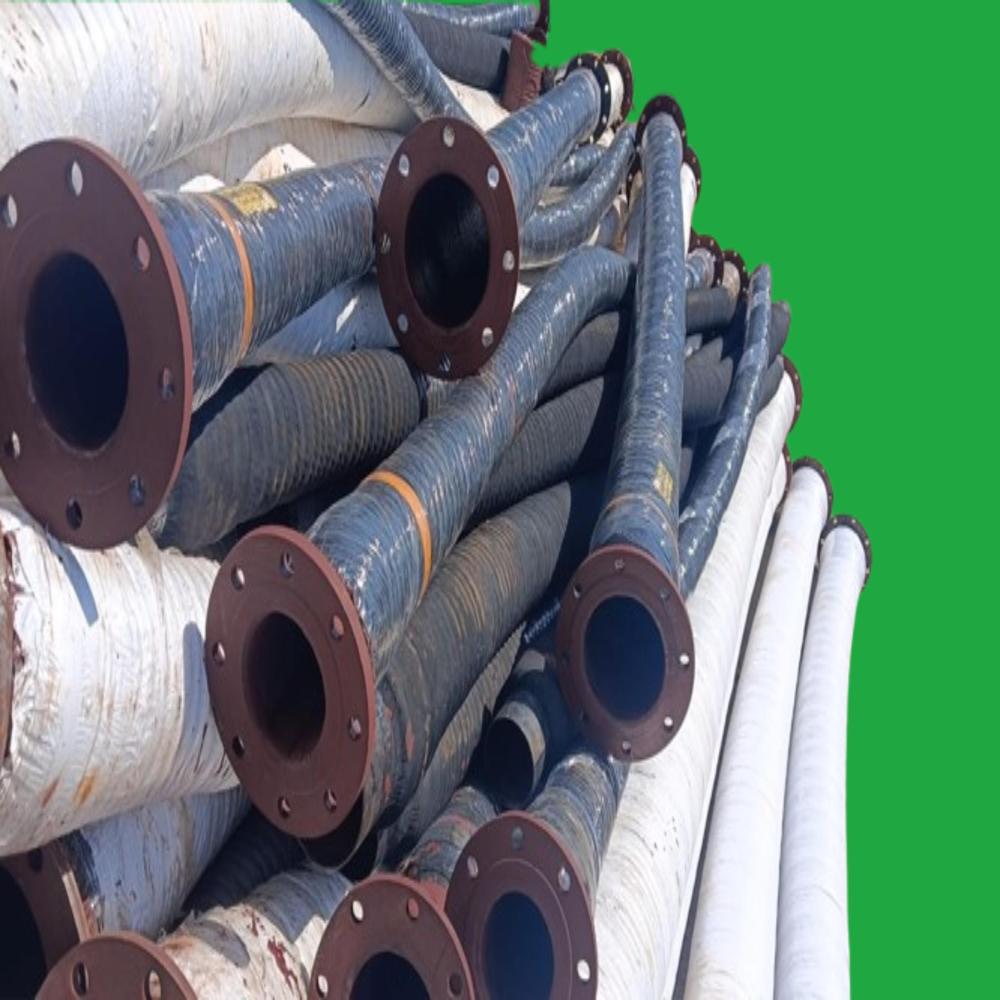

Cement Feeding Rubber Hose

Price 1600.0 INR/ Meter

Cement Feeding Rubber Hose Specification

- Hardness

- 72 5 Shore A

- Medium

- Cement, Sand, Dry Materials

- Reinforcement

- High strength textile plies with helical steel wire

- Cover

- Abrasion and weather resistant synthetic rubber

- Shape

- Round/Uniform Cylindrical

- Connection Type

- Flanged / Plain / Cuffed

- Material

- Rubber

- Temperature

- -30C to +80C

- Pressure

- 10 Bar (150 PSI)

- Inside Diameter

- 51 mm to 102 mm (2 to 4)

- Outside Diameter

- 63 mm to 120 mm (2.5 to 4.75)

- Weight

- 4.5 to 15 kg/meter

- Standard

- IS 1307:1992 / Equivalent

- Application

- Bulk material handling, cement feeding in construction & cement plants

- Flexibility

- Excellent

- Color

- Black

- Surface Finish

- Smooth

- Lining

- Wear resistant rubber compound

- Length

- 1 to 15 meters (Custom available)

- Burst Pressure

- Up to 30 Bar

- End Connection

- MS Flange / Plain

About Cement Feeding Rubber Hose

Versatile Applications: From Construction Sites to Cement Plants

The Cement Feeding Rubber Hose is designed for dynamic environments including major construction sites and sprawling cement plants. Its versatile build ensures compatibility with rugged surfaces, machinery outlets, and silo connections. Whether you're managing cement, sand, or dry bulk material, this hose delivers flawless performance across diverse industries-from dealer warehouses to manufacturer fabrication floors. Its flexibility allows seamless adaptation to changing site layouts and equipment surfaces, ensuring reliability wherever material is handled.

Sample Policy & Domestic Market: Premium Dispatching

Experience premium transportation and prompt dispatching of your Cement Feeding Rubber Hose sample, available for quality validation before bulk purchases. Serving India's main domestic market, our supplier network ensures samples reach fabricators, dealers, and retailers efficiently. Our sample policy prioritizes convenience and transparency, allowing traders and wholesalers to assess product durability and adaptability ahead of any procurement commitment. Trust in reliable logistics for timely arrival and exceptional product assurance within India.

FAQ's of Cement Feeding Rubber Hose:

Q: How can the Cement Feeding Rubber Hose be customized for different length requirements?

A: You can select hoses in lengths from 1 to 15 meters, or request a custom size to precisely fit your material handling needs or installation parameters.Q: What is the process for requesting a sample of the Cement Feeding Rubber Hose?

A: Samples are dispatched promptly upon request, allowing you to evaluate quality and suitability before finalizing a larger purchase through our transparent, premium sample policy.Q: Where is this hose commonly used in bulk material handling applications?

A: The Cement Feeding Rubber Hose is primarily utilized in construction sites and cement plants but is also suitable for various industrial setups dealing with sand, cement, and dry materials.Q: When is the right time to replace the existing hose with this top-rated product?

A: It's optimal to consider replacement when experiencing wear, reduced flexibility, or lower performance; our best-seller delivers flawless operation under challenging conditions and meets rigorous standards.Q: How does the wear-resistant rubber lining benefit usage in harsh environments?

A: The remarkable wear-resistant compound ensures durability against abrasion and heavy material flow, boosting service life and reliability during continuous operation.Q: What end connection options are available, and how do they affect installation?

A: Choose from MS Flange, Plain, or Cuffed ends. These options facilitate secure attachment and simplified connectivity with various industrial systems or bulk handling setups.Q: What is the standard followed for making the Cement Feeding Rubber Hose?

A: Manufacturing adheres to IS 1307:1992 and equivalent standards, ensuring quality, safety, and performance for all bulk handling operations in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Feeding Rubber Hose Category

Cement Feeding Rubber Hose

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

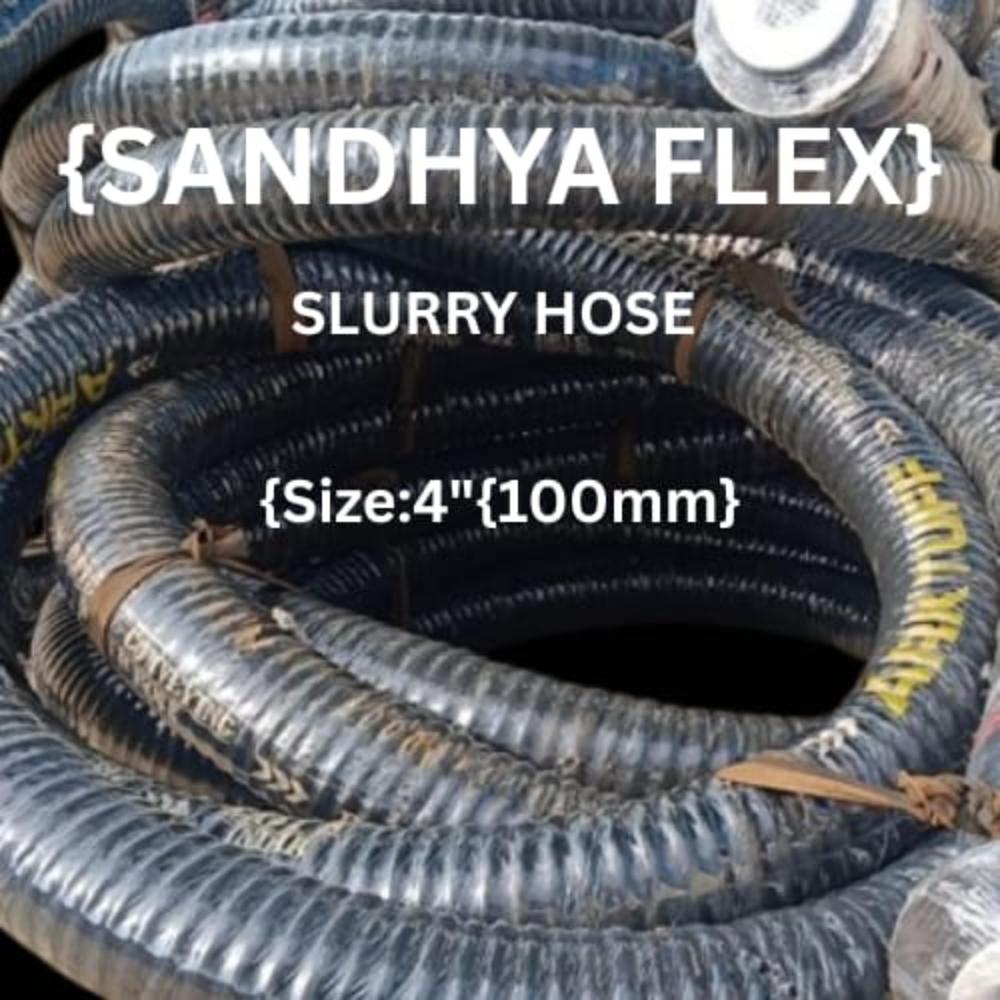

Shape : Round

Connection Type : [](https://www.sandhyaflex.com/slurryandmudrubberhose.html?utm_source=chatgpt.com) The **SANDHYAFLEX Slurry Rubber Hose** is designed with specific connection types to ensure durability and efficiency in handling abrasive materials. ### Connection Types 1. **Builtin Flange Connection** * **Standard**: Most commonly, these hoses come with builtin flanges made of **Mild Steel (MS)**, conforming to **ASA 150# ANSI 16.5 Drilled and DIN specifications**. * **Applications**: Ideal for highpressure slurry transport in industries like mining, construction, and dredging. * **Sizes**: Available in diameters ranging from **6 inches (150mm) to 10 inches (250mm)**, with lengths up to **15 meters**. ([Sandhya Enterprises][1]) 2. **Camlock Fitting** * **Features**: Some hoses are equipped with **Camlock fittings**, which are quickconnect couplings made from materials like **aluminum, stainless steel, or brass**. * **Advantages**: These fittings allow for rapid connection and disconnection, making them suitable for temporary setups or applications requiring frequent hose changes. * **Specifications**: Typically, these hoses have a **working pressure of 25 bar** and are constructed with **6 layers** for enhanced durability. ([sandhyaenterprises.co.in][2]) 3. **Dredge Delivery Hose** * **Design**: For specialized applications like dredging, hoses are manufactured with **rubberized builtin steel/rubber flanges**. * **Reinforcement**: These hoses are reinforced with **hightensile steel wires** and are designed to handle extreme pressures. * **Pressure Ratings**: They are tested for a **proof pressure of 20 kg/cm **, with a burst pressure designed to be **four times the working pressure**. ([Sandhya Enterprises][3]) ### Summary | Connection Type | Material | Pressure Rating | Common Applications | | | | | | | Builtin Flange | MS (Mild Steel) | Up to 25 bar | Mining, construction, dredging | | Camlock Fitting | Aluminum/Stainless Steel | Up to 25 bar | Temporary setups, frequent changes | | Dredge Delivery Hose | Rubberized Steel Flanges | High Pressure | Dredging, heavyduty slurry transport | Each connection type is tailored to specific operational needs, ensuring optimal performance and safety in various industrial applications. If you need further details or assistance in selecting the appropriate hose for your application, feel free to ask! [1]: https://www.sandhyaflex.com/slurryandmudrubberhose.html?utm_source=chatgpt.com "Slurry and Mud Rubber Hose Sandhya Enterprises" [2]: https://www.sandhyaenterprises.co.in/marinerubberhose.html?utm_source=chatgpt.com "Marine Rubber Hose ASA 150 Class Flange Fitting ..." [3]: https://www.sandhyaflex.com/dredgehose.html?utm_source=chatgpt.com "Dredge Delivery Rubber Hose Sandhya Enterprises"

Cover : The **cover of a Sandhyaflex Cement Feeding Rubber Hose** is specifically designed to **protect the hose from external damage, abrasion, and environmental factors**, while ensuring safety during cement handling. Here s a detailed breakdown: ### **1. Material** * Made from **highquality synthetic rubber compounds**, often blended with natural rubber. * **Abrasionresistant** to withstand contact with rough surfaces, equipment, and cement particles. * **Weather and UV resistant**, suitable for outdoor use at construction sites. * Resistant to **oil, grease, and chemical splashes** that may be present on construction or industrial sites. ### **2. Surface and Design** * **Clothmarked or smooth finish** to reduce friction and wear during operation. * Flexible enough to allow **easy handling and bending** without damaging the hose. * Designed to **prevent ingress of dirt or water** that could compromise hose performance. ### **3. Additional Features** * Some hoses include **embedded copper wire** for **electrical continuity**, preventing static charge buildup when transferring dry cement or powders. * The cover works in tandem with the inner lining and reinforcement to provide **overall hose durability and long service life**. ### ** Key Benefits** * **Enhanced Durability:** Protects the hose against mechanical wear and environmental factors. * **Safety:** Reduces risk of hose failure and static buildup during cement transfer. * **Versatility:** Suitable for **construction sites, cement plants, and industrial applications**. If you want, I can make a **full diagram showing the layers of Sandhyaflex Cement Feeding Rubber Hose**, including **lining, reinforcement, and cover**, so you can see it visually. This is often very helpful for technical understanding. Do you want me to make that diagram?

Material : Rubber

Cement Air Rubber Hose

Price 1200.0 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : Round

Connection Type : Plain or Flanged Ends

Cover : Abrasion and weatherresistant rubber, black or brown colour

Material : Other, Natural & Synthetic Rubber Blends

Plain End Cement Feeding Rubber Hose

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : Round

Connection Type : Plain End

Cover : Abrasion and weatherresistant rubber cover

Material : Other, Synthetic Rubber

125NB Concreate End Hose

Price 17000.0 INR / Number

Minimum Order Quantity : 1 Number

Shape : Round / Straight

Connection Type : Flanged / Groove Coupling

Cover : Abrasion resistant synthetic rubber, black, smooth finish

Material : Other, High quality synthetic rubber blend

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS