Elastomeric Bridge Bearing

Price 18000.0 INR/ Number

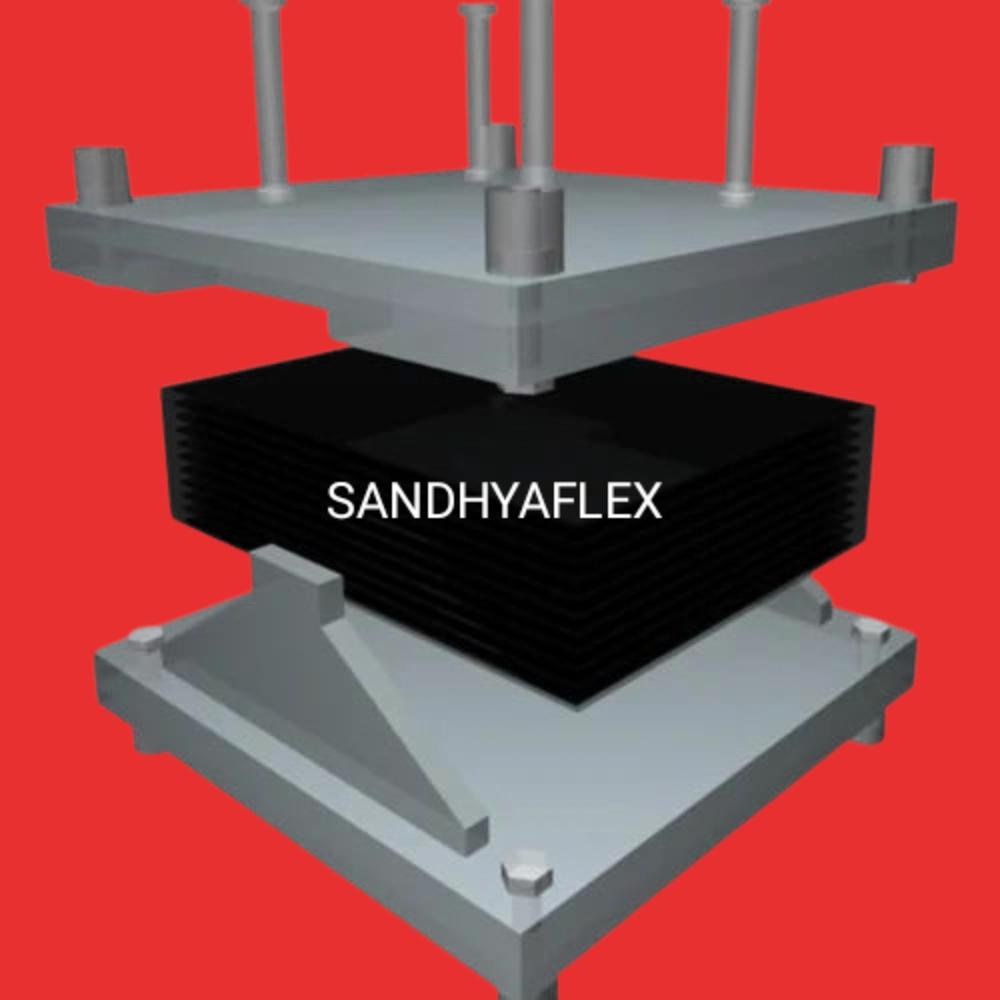

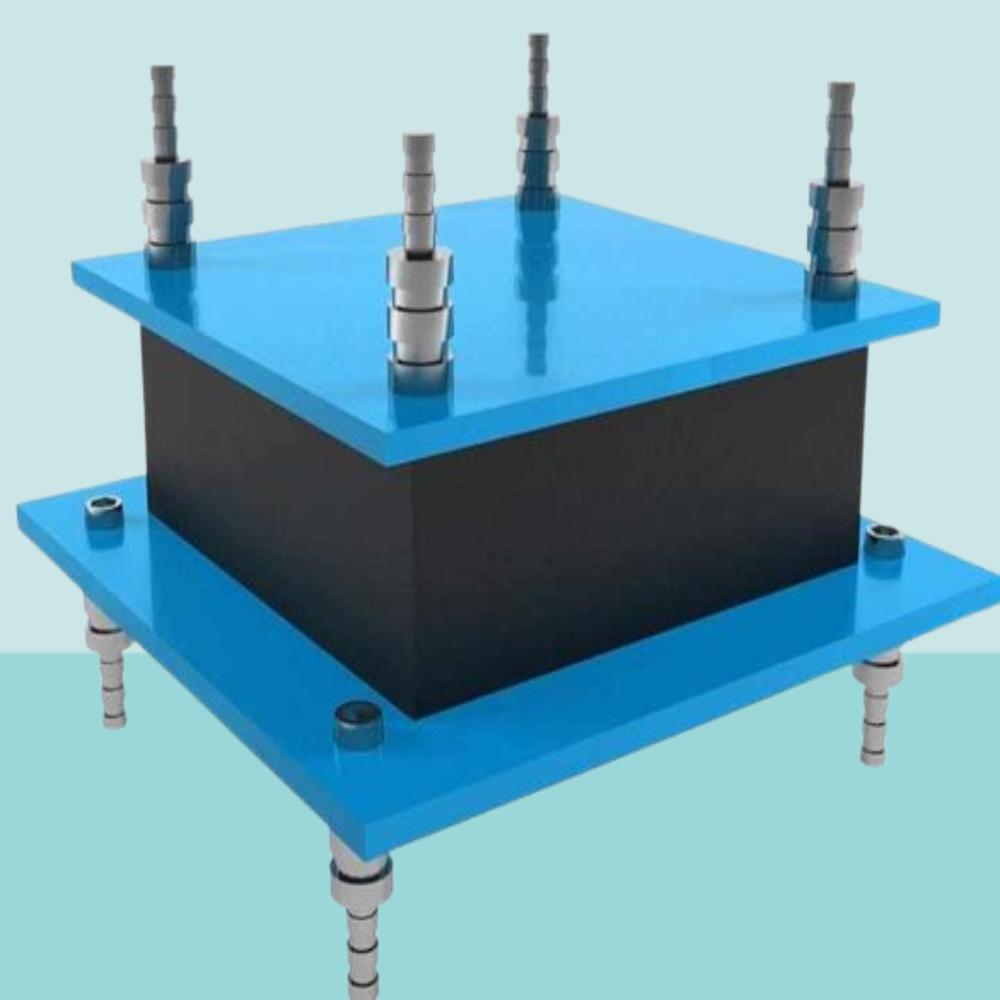

Elastomeric Bridge Bearing Specification

- Lubrication Type

- No lubrication required

- Thickness

- 12 mm to 300 mm (as per requirement)

- Inside Diameter

- Customized

- Precision Rating

- Standard as per IS:3400, IRC:83 Part II, and MoRTH guidelines

- Bearing Type

- Elastomeric

- Material

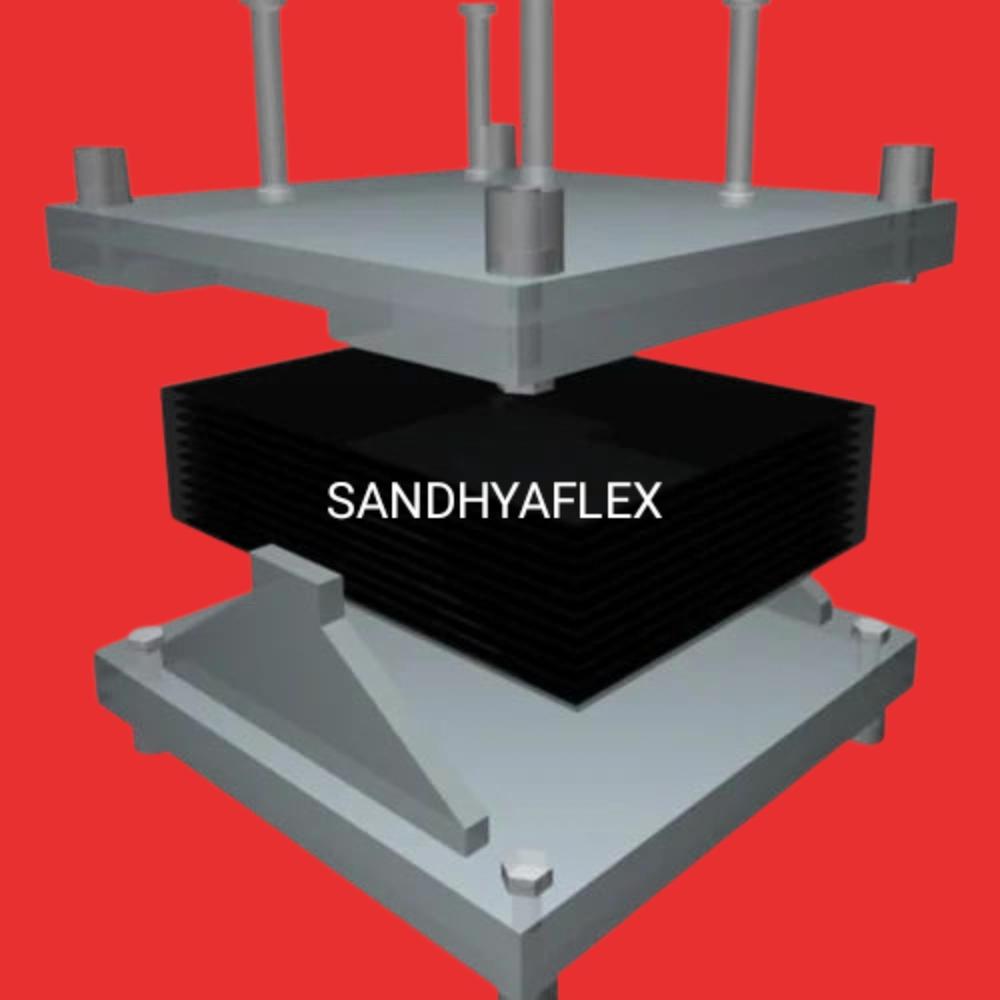

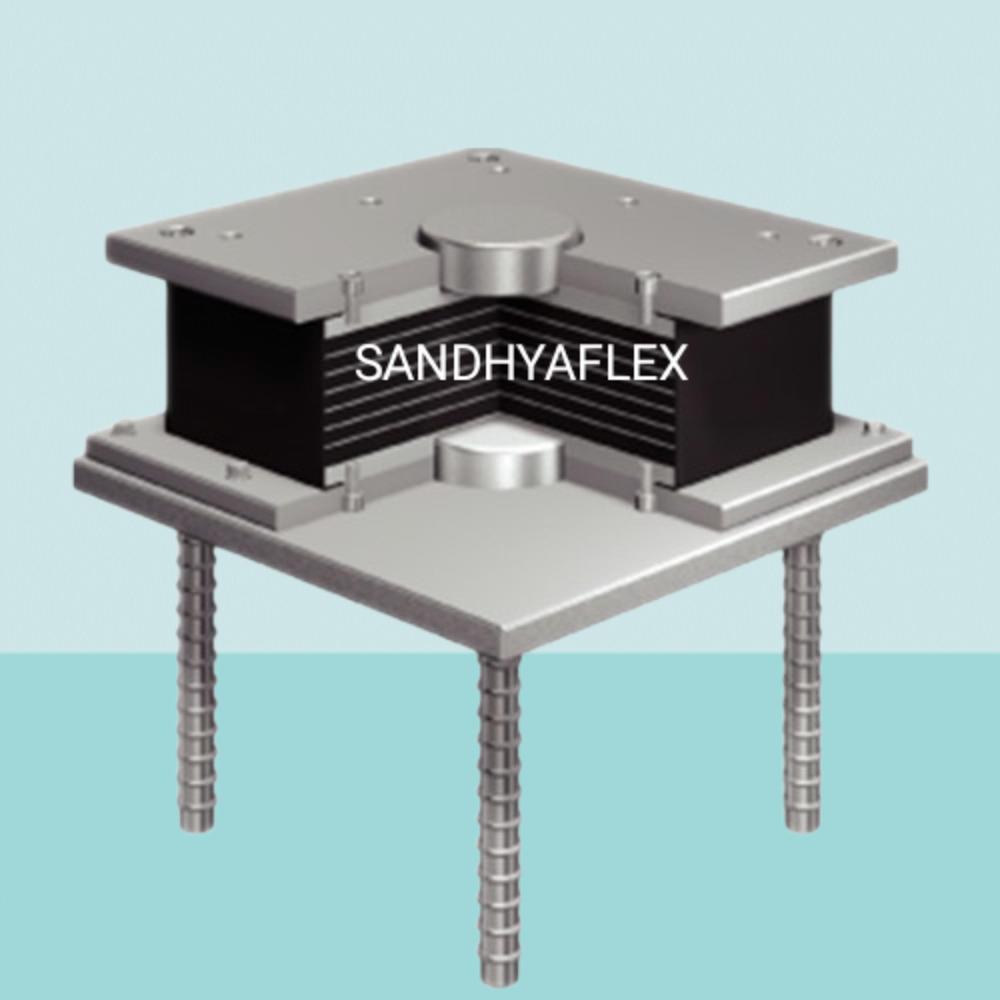

- Natural Rubber/Neoprene with Steel Plates

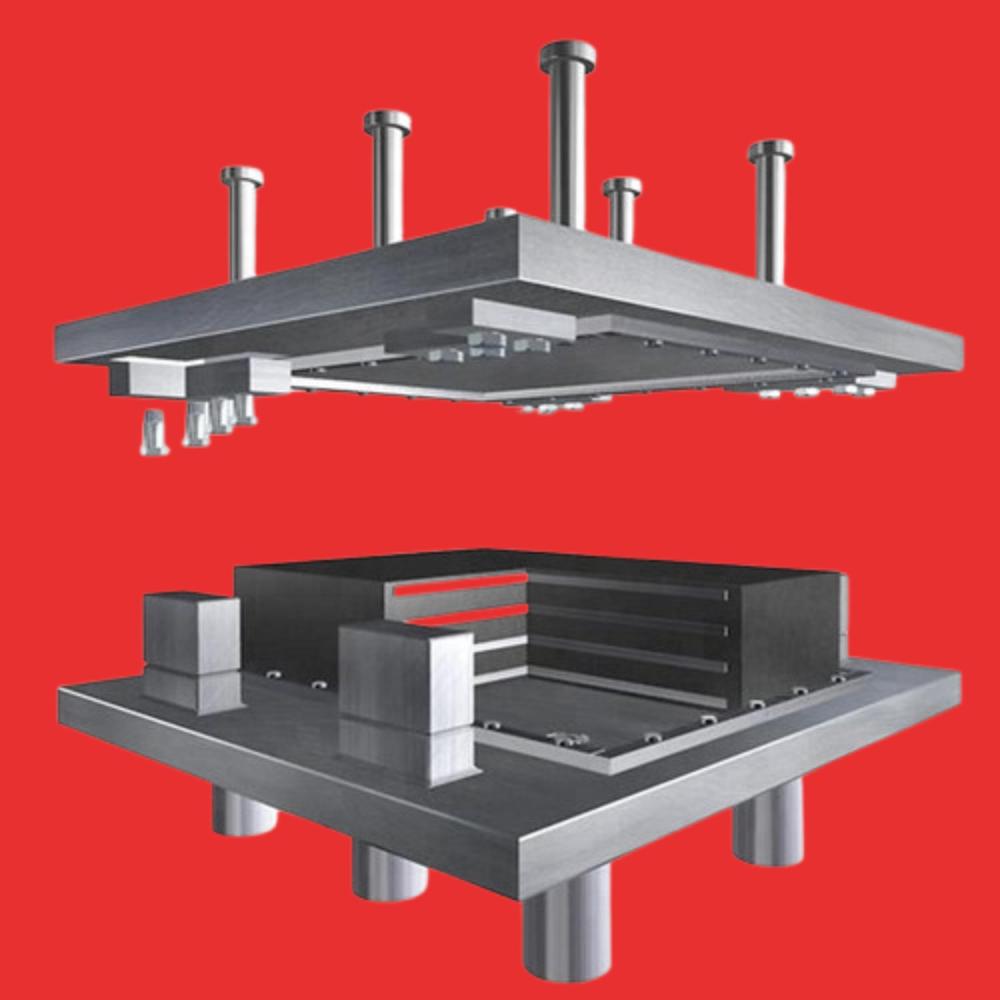

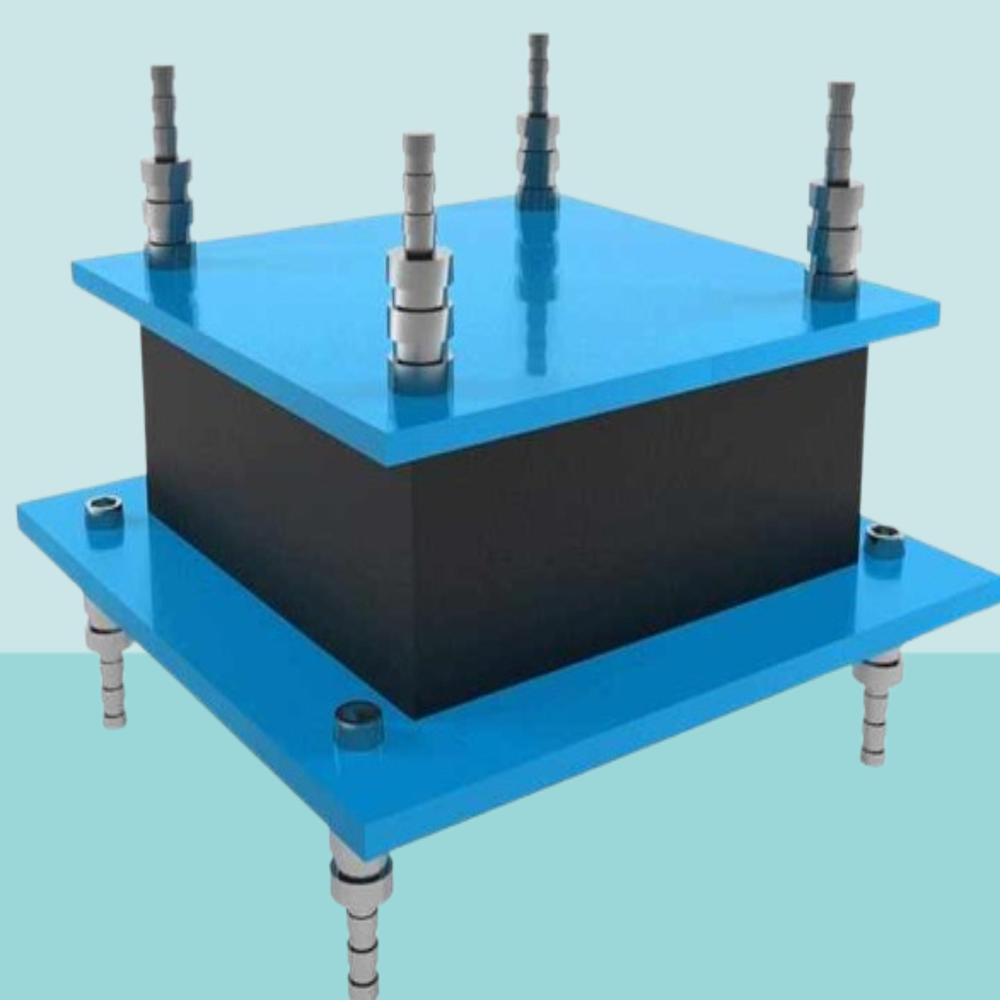

- Structure

- Laminated

- Seals Type

- Non-sealed

- Number Of Rows

- Single

- Bore Size

- Customized

- Outside Diameter

- Customized

- Load Capacity

- Up to 1000 kN or as required

- Compliance

- IS:3400 / IRC:83 / MoRTH standard

- Hardness

- 60±5 Shore A

- Finish

- Smooth Surface Finish

- Tear Strength

- Min 15 N/mm

- Test Certificate

- Available on request

- Application

- Bridge & Flyover Deck Support, Structural Isolation

- Temperature Resistance

- -40°C to +70°C

- Packaging Type

- Wooden Box or As required

- Service Life

- Up to 30 years under normal conditions

- Color

- Black

- Installation

- Direct mounting between substructure and superstructure

- Shape

- Rectangular or Circular

About Elastomeric Bridge Bearing

Applications and Versatility of Elastomeric Bridge Bearings

Elastomeric Bridge Bearings are expertly engineered for bridge and flyover deck support, ensuring optimal structural isolation. Used as a vital component in the substructure and superstructure interface, these bearings prevent direct contact and help distribute loads evenly. Their versatility extends across various civil and infrastructure projects, adapting to rectangular or circular application media to suit customized structural needs. This advanced bearing is indispensable for highway overpasses, railway bridges, and commercial construction sites demanding reliability.

Supply Capability, Delivery, and Certifications

With Stock Ready and swift Goods Transport solutions, Elastomeric Bridge Bearings are available at the lowest price for bulk buyers and single orders. Certified under IS:3400, IRC:83 Part II, and MoRTH standards, every batch can be accompanied by a test certificate upon request. Supply ability is robust, supporting consistent demand across India, and delivery time is minimized by optimized logistics networks, ensuring timely arrival. Experience seamless procurement for dealers, fabricators, and contractors.

FAQ's of Elastomeric Bridge Bearing:

Q: How does the Elastomeric Bridge Bearing contribute to structural isolation?

A: The Elastomeric Bridge Bearing is designed to separate the substructure from the superstructure, absorbing movements and loads to provide effective isolation. This ensures the bridge or flyover is protected from vibration, expansion, and contraction, enhancing structural longevity.Q: What materials are used in manufacturing these bridge bearings?

A: They are manufactured using natural rubber or neoprene combined with steel plates. This composition provides a formidable tear strength, temperature resistance, and compliance with IS:3400, IRC:83, and MoRTH standards.Q: When should elastomeric bearings be installed in bridge construction?

A: Elastomeric bearings are installed directly during the construction phase between the substructure and superstructure, right after completion of the primary structural elements. Proper positioning facilitates long-term load management and isolation.Q: Where can I request a test certificate for my elastomeric bearing purchase?

A: Test certificates for quality and compliance are available on request from the manufacturer, supplier, or retailer. You may specify this requirement during order placement for authentication and documentation.Q: What is the benefit of a laminated structure and customized dimensions?

A: A laminated structure offers increased flexibility and load-bearing capacity, while customization in bore size, thickness, and diameter ensures the bearing fits precise project specifications, maximizing performance.Q: How long is the expected service life under normal conditions?

A: Under standard usage and environmental conditions, these bearings deliver a noteworthy service life of up to 30 years, minimizing maintenance and replacement needs for infrastructure projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Elastomeric Bridge Bearing Category

Heavy Duty Elastomeric Bridge Bearing

Price 3265 INR / Cubic Centimeter

Minimum Order Quantity : 100 Cubic Centimeters

Lubrication Type : Other

Material : Rubber

Number Of Rows : Other

Structure : Sliding Bridge Bearing. A friction force is generated in sliding bearing and it is imposed on substructure, superstructure and sliding bearing itself. Rocker Bridge Bearing. Rocker Bridge Bearing. Pin bearing is a fixed bearing that make room for rotation movement through the application of steel pin. It has similar structure and component like rocker bearing apart from the bottom of pin bearing which is flat and fixed to the concrete pier, as can be observed in Figure4. Pin Bearing for Bridges. Both rocker and pin bearings are mainly employed in steel bridge structure. Rocker and pi

Drainage spout

Price 1500 INR / Number

Minimum Order Quantity : 50

Lubrication Type : Other

Material : Stainless Steel

Mounting with Stud

Price 370.0 INR / Piece

Minimum Order Quantity : 1 Piece

Lubrication Type : Other, Prelubricated (Grease)

Material : Other, Chrome Steel (SUJ2)

Number Of Rows : Single Row

Structure : Mounting with Stud

L Type Spider Seris Pad

Price 90.0 INR / Number

Minimum Order Quantity : 1 Number

Lubrication Type : Other, No lubrication required (drytype flexible pad)

Material : Other, High Quality Polyurethane Rubber

Number Of Rows : Single Row

Structure : L Type Spider Series

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free