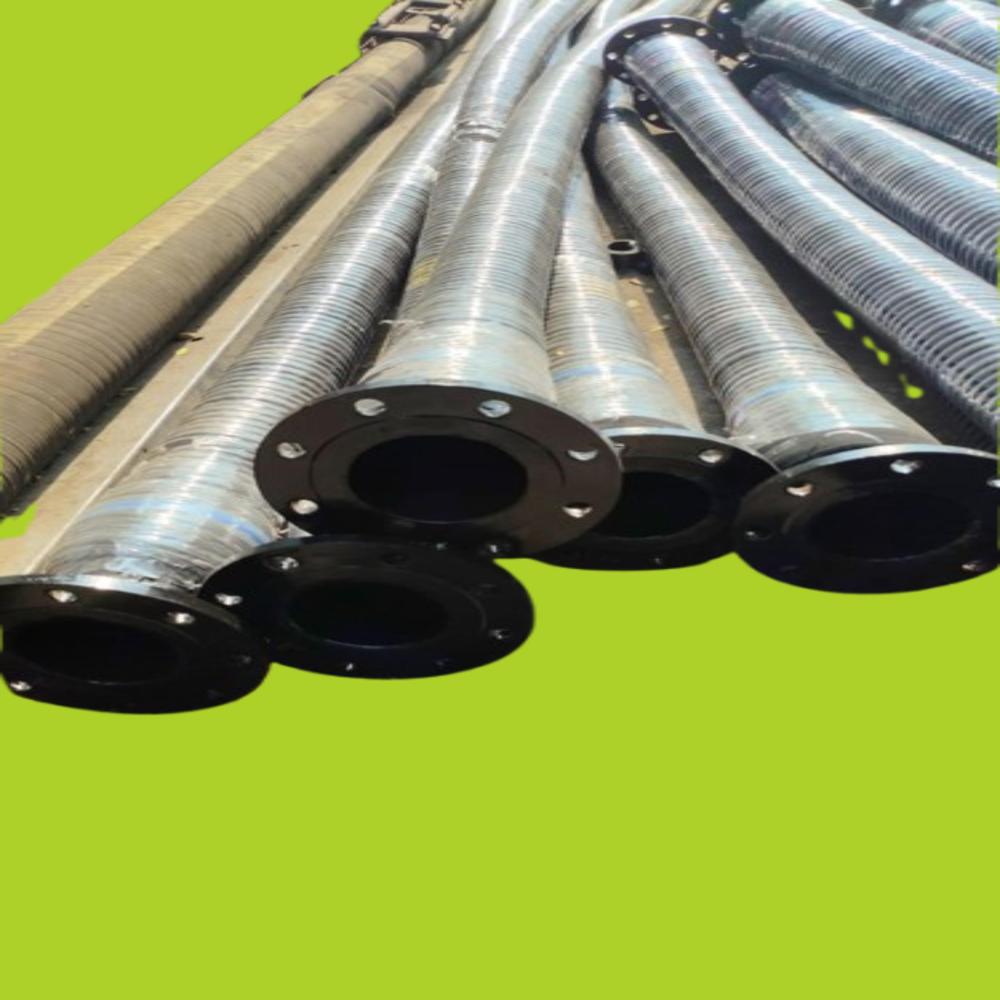

Cement Feeding Rubber Hose with fixed Flange

Price 1600.0 INR/ Meter

Cement Feeding Rubber Hose with fixed Flange Specification

- Medium

- Cement, Fly Ash, Dry Bulk Materials

- Reinforcement

- Textile plies with helical wire

- Hardness

- 65 5 Shore A

- Connection Type

- Fixed Flange

- Shape

- Round

- Cover

- Abrasion resistant synthetic rubber

- Material

- Natural & Synthetic Rubber

- Temperature

- -30C to +80C

- Pressure

- 10 to 20 Bar

- Inside Diameter

- 51 mm to 152 mm

- Outside Diameter

- 65 mm to 170 mm

- Color

- Black

- Bursting Pressure

- Up to 60 Bar

- Working Life

- 2500+ hours

- Weight

- Variable as per length and diameter

- Flexibility

- High, with kink resistance

- Application

- Cement feeding in construction and RMC plants

- Temperature Resistance

- Resistant to both high and low temperatures

- End Connection

- Mild Steel (MS) Fixed Flange as per IS 513

- Inner Tube

- Smooth, seamless rubber compound

- Length

- Up to 15 meters

- Odor

- Odorless

About Cement Feeding Rubber Hose with fixed Flange

Heres a refined and professional product description for your Cement Feeding Rubber Hose with Fixed Flange under your brand Sandhya Enterprises. Its suitable for catalogs, brochures, technical sheets, or your website:

Cement Feeding Rubber Hose with Fixed Flange

Brand: Sandhya Enterprises

Product Code: SE-CF-RH-FL

Product Overview:

The Cement Feeding Rubber Hose with Fixed Flange by Sandhya Enterprises is purpose-built for the pneumatic transfer of bulk cement and fine powders. Designed to withstand abrasion, pressure, and harsh weather, this heavy-duty hose is ideal for cement bulker unloading, silo feeding, and concrete batching plants.

Technical Construction:

-

Tube: Abrasion and wear-resistant blend of natural and synthetic rubber compatible with dry cement, fly ash, and similar materials.

-

Reinforcement: High-tensile synthetic plies with optional steel wire helix for added strength and vacuum resistance.

-

Cover: Anti-static, weatherproof, and ozone-resistant synthetic rubber (Black).

-

End Connection: Fixed MS or SS Flange (IS/ANSI/DIN standards), hot vulcanized with the hose body for a leak-proof, secure bond.

Technical Specifications:

| Feature | Specification |

|---|---|

| Inner Diameter | 2" to 6" (50 mm to 150 mm) |

| Length | Up to 15 meters (custom lengths available) |

| Working Pressure | 10 to 15 Bar |

| Burst Pressure | Up to 30 Bar |

| Temperature Range | -30C to +100C |

| End Fittings | Fixed MS/SS Flange (as per standards) |

| Vacuum Rating | Optional steel wire for suction handling |

| Branding | Sandhya Enterprises printed on cover |

Applications:

-

Cement bulker to silo connections

-

Pneumatic conveying in RMC & batching plants

-

Fly ash and cement transfer systems

-

Construction sites, cement plants, and industrial storage units

Highlights:

High flexibility and kink resistance

Excellent abrasion and weather resistance

Durable flange bonding for leak-proof performance

Custom sizes and pressure ratings available on request

Let me know if youd like this formatted into a PDF datasheet, a web product listing, or with certification details and testing reports (like hydro test, burst test, etc.). I can also draft a matching version for fly ash, silo, or unloading hoses if needed.

Robust Construction for Demanding Applications

This hose is crafted with high-grade natural and synthetic rubber, meeting the rigorous requirements of cement and fly ash handling. The reinforcement of textile plies with a helical wire provides durability and flexibility under pressure, ensuring a long operational life and reduced risk of rupture or leakage during tough construction activities.

Tailored Flexibility and Easy Installation

Offered in variable lengths and diameters, this hose ensures convenience for different site requirements. The fixed mild steel flanges (as per IS 513) allow secure and rapid connections, ensuring operational efficiency for dealers, manufacturers, and fabricators across India. Its high kink resistance and seamless inner tube make installation straightforward and reliable.

FAQ's of Cement Feeding Rubber Hose with fixed Flange:

Q: How is this hose typically used in construction and RMC plants?

A: The hose is primarily used for transferring cement, fly ash, and dry bulk materials from storage silos or tanks to mixers or batching plants, ensuring efficient, dust-free, and continuous material flow during construction and ready-mix concrete operations.Q: What are the benefits of using a fixed flange end connection for this hose?

A: A fixed flange (MS, as per IS 513) enables secure, leak-proof attachment to the equipment, reduces installation time, and provides the strength needed for high-pressure applications, making maintenance and replacement of hoses more efficient.Q: When should the hose be replaced for optimal performance?

A: Although designed for a working life of over 2,500 hours, regular inspection is recommended. The hose should be replaced if there are visible cracks, bulges, leaks, or significant wear on the inner or outer cover, or if its flexibility decreases markedly.Q: Where can this hose be installed or applied?

A: This hose is suitable for use at construction sites, ready-mix concrete (RMC) plants, cement manufacturing facilities, and anywhere bulk dry materials need to be moved efficiently. Its design allows for both indoor and outdoor installation in Indian working conditions.Q: What makes this hose resistant to temperature fluctuations and abrasion?

A: The use of high-quality natural and synthetic rubber compounds along with a specially formulated abrasion-resistant outer cover allows the hose to perform reliably between -30C and +80C and withstands the abrasive action of dry materials, prolonging service life.Q: How does textile and helical wire reinforcement enhance the hose's performance?

A: Textile plies provide strength and flexibility, while the embedded helical wire prevents collapsing under vacuum and ensures structural integrity under higher working pressures, guaranteeing safe and efficient cement feeding even in demanding scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Feeding Rubber Hose Category

Cement Feeding Rubber Hose

Price 2900.0 INR / Meter

Minimum Order Quantity : 1 Meter

Pressure : 10 kgf/cm2

Temperature : 70 Celsius (oC)

Cover : Rubber

Shape : Round

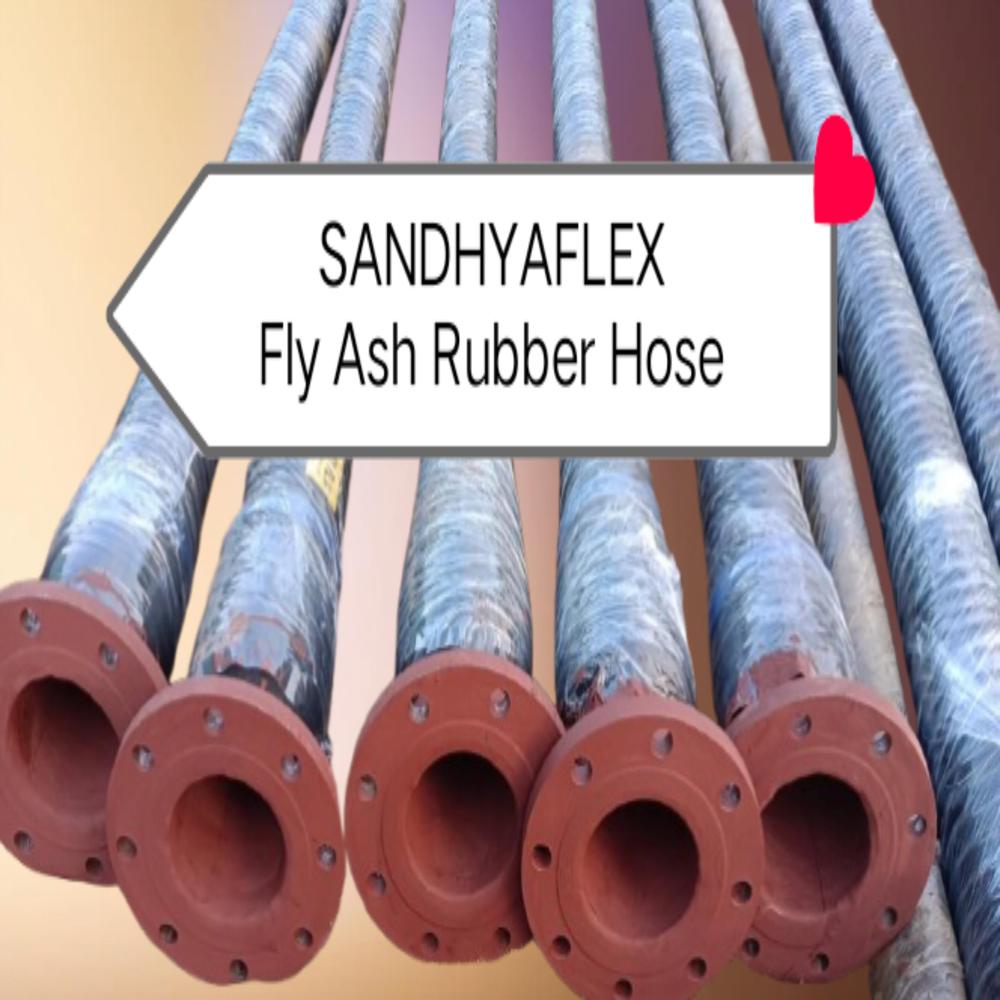

Fly Ash Rubber Hose

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

Pressure : 10 kgf/m2

Temperature : 70 Celsius (oC)

Cover : Rubber

Shape : Round

Cock Injection Rubber Hose

Price 1800.0 INR / Meter

Minimum Order Quantity : 1 Meter

Pressure : 10 kg/cm

Temperature : 20C to +120C

Cover : Smooth Rubber

Shape : Round

Cement Feeding Rubber Hose

Price 2400.0 INR / Meter

Minimum Order Quantity : 1 Meter

Pressure : 2030 Bar

Temperature : Up to 80C

Cover : Abrasion, Weather, and Oil Resistant Rubber

Shape : Straight

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free