Cement Feeding Rubber Hose

Price 2100.0 INR/ Meter

Cement Feeding Rubber Hose Specification

- Reinforcement

- Tire Cord and Helicles wire

- Connection Type

- MS Flange as per ASA 150#

- Medium

- Air

- Hardness

- 60 Shore A

- Cover

- Rubber

- Shape

- Round

- Usage

- Cement conveying & feeding in batching plants and cement factories. Bulker/truck loading & unloading of cement, fly ash, sand and powders. In-plant transfer between silos, hoppers and mixers. Spraying cement grout at irrigation projects, dams, buildings, bridges and roads. Pneumatic conveying systems in RMC and industrial plants

- Material

- Rubber

- Size

- 125mm ID

- Height

- 7 Meter (m)

- Temperature

- 70 Celsius (oC)

- Product Type

- Cement Feeding Rubber Hose

- Pressure

- 10 kgf/m2

- Inside Diameter

- 100 Millimeter (mm)

- Weight

- 7 Kilograms (kg)

- Color

- Rubber

- Outside Diameter

- 125 Millimeter (mm)

- Width

- 125 Millimeter (mm)

- Length

- 6 Meter (m)

- Warranty

- 6Month

Cement Feeding Rubber Hose Trade Information

- Minimum Order Quantity

- 1 Meter

- Delivery Time

- 1 Week

About Cement Feeding Rubber Hose

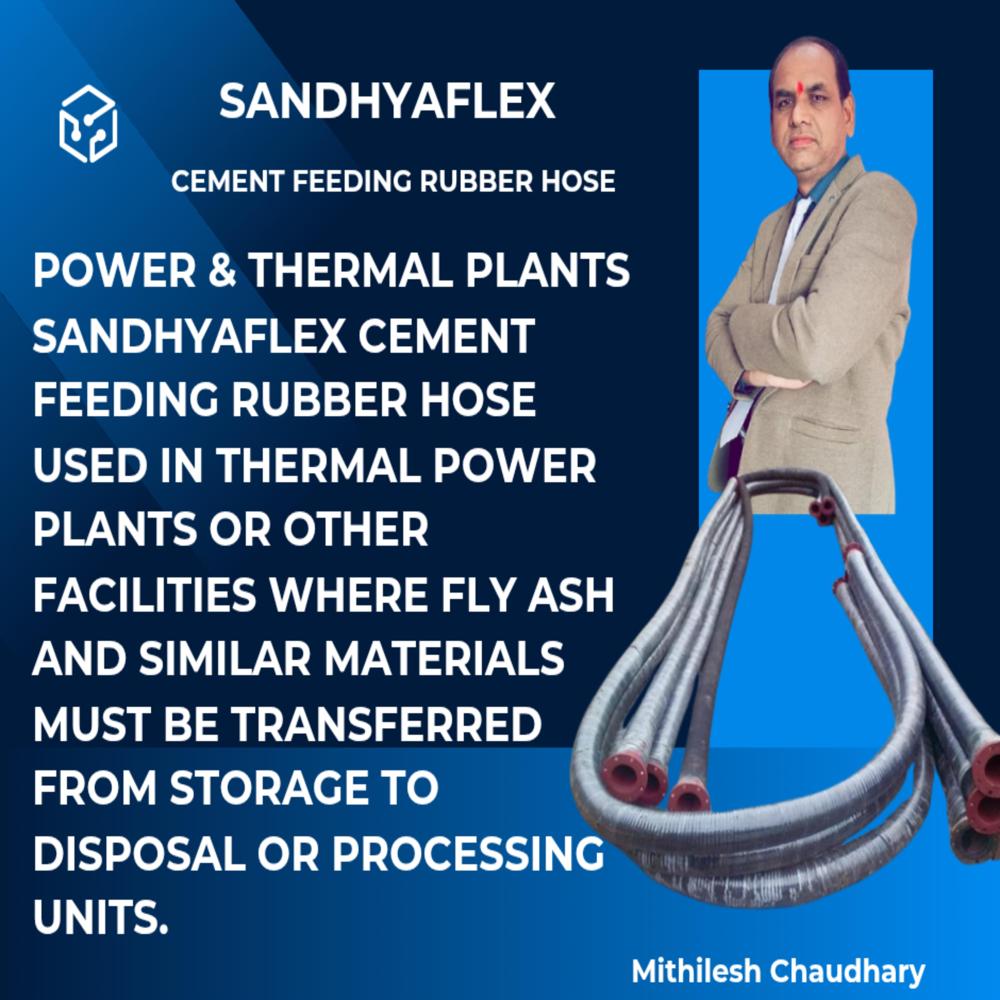

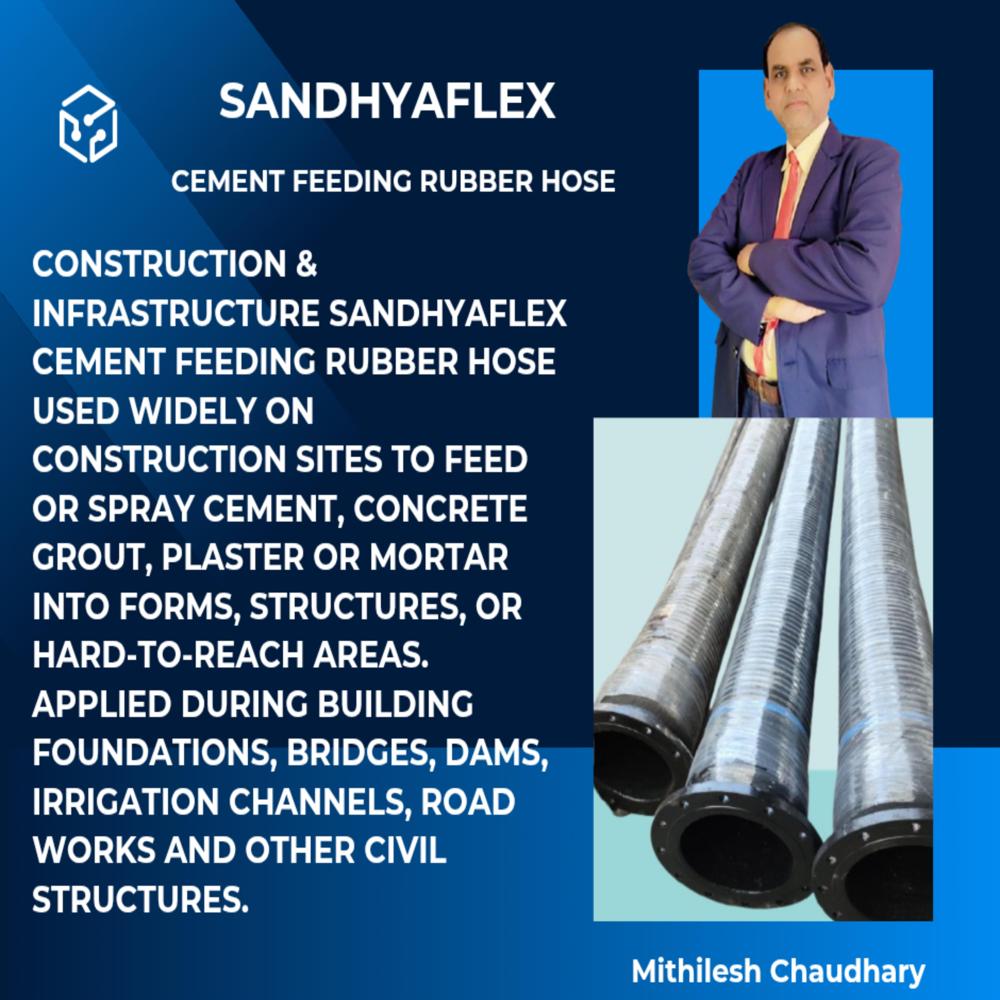

Heres a clear overview of SANDHYAFLEX Cement Feeding Rubber Hose a heavy-duty industrial hose used in construction, cement plants and material handling systems:

Cement Feeding Rubber Hose

1,800

Cement Feeding Rubber Hose With Flange

1,800

Black Cement Feeding Rubber Hose 6m

750

Cement Feeding Fly Ash Hose

450

Cement Feeding Rubber Hose - Mild Steel

9,000

Cement Grouting Hose

950

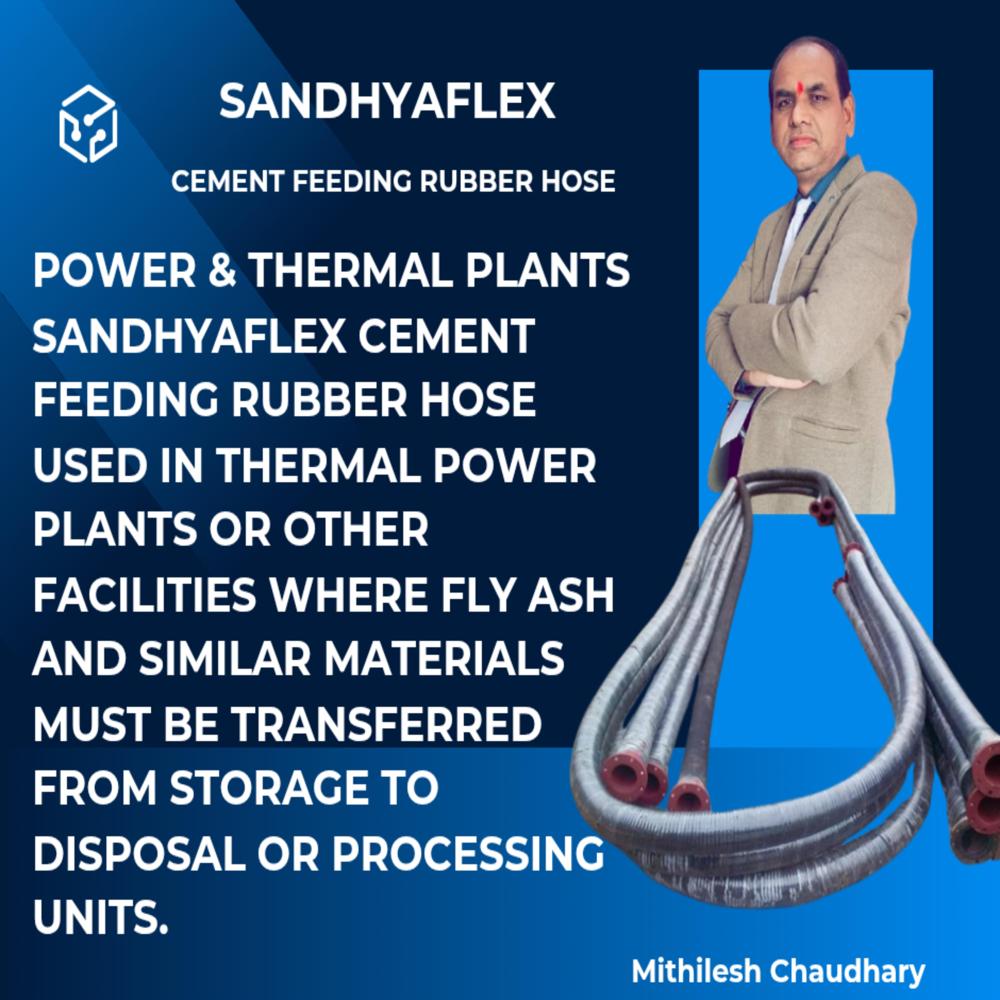

What It Is

A Cement Feeding Rubber Hose is an abrasion-resistant flexible hose designed for pneumatic conveying, suction/discharge, and feeding of dry cement, fly ash, lime, sand and similar abrasive bulk materials. Its engineered for tough industrial environments where rigid piping isnt practical and heavy wear is expected. (Sandhya Enterprises)

Construction & Materials

Inner Lining:

Seamless, thick tube made of natural and synthetic rubber blend that resists abrasion and wear from high-velocity dry bulk materials. (Sandhya Enterprises)

Reinforcement:

Multiple layers of synthetic textile cords and sometimes steel wire helix for strength, flexibility, pressure resistance and kink control. (Sandhya Flex)

Outer Cover:

Weather-, ozone- and abrasion-resistant rubber compound to survive outdoor and rough environments. (Sandhya Flex)

Electrical Bonding Wire:

Some hoses include a copper wire strand in the reinforcement for electrical continuity (prevents static buildup). (Sandhya Enterprises)

End Fittings:

Can be supplied with built-in flanges, camlocks, MS nipples, or threaded ends depending on application. (sandhyaenterprises.co.in)

Key Specifications (Typical)

| Feature | Typical Value |

|---|---|

| Working Pressure | 10 bar (10 kg/cm) (Sandhya Enterprises) |

| Proof Pressure | 1.5 working pressure (Sandhya Enterprises) |

| Burst Pressure | 3 working pressure (Sandhya Flex) |

| Temperature Range | 1 C to +70 100 C (sandhyaenterprises.co.in) |

| Vacuum Capacity | 700 mm Hg (0.9 bar) (sandhyaenterprises.co.in) |

| Lengths | Typically up to 15 m (custom lengths on request) (Sandhya Enterprises) |

| Available Sizes | 75 mm (3) to 300+ mm (12+) ID, various fittings (Sandhya Enterprises) |

Main Uses

Cement conveying & feeding in batching plants and cement factories. (sandhyaenterprises.co.in)

Bulker/truck loading & unloading of cement, fly ash, sand and powders. (sandhyaenterprises.co.in)

In-plant transfer between silos, hoppers and mixers. (sandhyaenterprises.co.in)

Spraying cement grout at irrigation projects, dams, buildings, bridges and roads. (Sandhya Enterprises)

Pneumatic conveying systems in RMC and industrial plants. (sandhyaenterprises.co.in)

Why Use This Hose?

Abrasion Resistance

The robust inner lining resists wear from abrasive dry bulk materials like cement and fly ash prolonging hose life. (Sandhya Enterprises)

Flexible & Durable

Offers flexibility around equipment and piping layouts while maintaining strength under pressure and vacuum. (Sandhya Flex)

High Pressure Handling

Designed to work under industrial pressures (10 bar) and withstand surges and vacuum conditions. (sandhyaenterprises.co.in)

Weather & Chemical Resistance

Outer cover resists weathering, aging, ozone and rejects moisture penetration, making it suitable for outdoor sites. (Sandhya Flex)

Electrical Continuity (Optional)

Embedded copper wire gives a safe path for static discharge useful in dry powder handling. (Sandhya Enterprises)

Product Examples You Can Consider

-

Cement Feeding Rubber Hose Standard cement feeding hose, abrasion-resistant.

-

Cement Feeding Rubber Hose With Flange With built-in flanges for easy connection.

-

Black Cement Feeding Rubber Hose 6m Pre-cut hose length for quick use.

-

Cement Feeding Fly Ash Hose Flexible option for fly ash and light powders.

-

Cement Feeding Rubber Hose - Mild Steel Industrial-strength version with MS fittings.

-

Cement Grouting Hose Good choice for grout applications.

Installation & Tips

Fit the hose between rigid pipes or equipment using flanges or camlock couplings suitable for your system. (sandhyaenterprises.co.in)

Avoid sharp bends follow recommended minimum bend radius (10 hose ID) to prevent damage. (sandhyaenterprises.co.in)

For long runs, consider support clamps to minimize stress on connections. (Sandhya Enterprises)

In summary: Sandhyaflex Cement Feeding Rubber Hose is a durable, flexible, abrasion-resistant hose built for efficient and reliable transfer of cement and other dry bulk materials in industrial and construction applications. (sandhyaenterprises.co.in)

If you share your required hose diameter and length (e.g., 100 mm 10 m), I can help pick the best size and end-fitting combo for your setup.

Robust Construction for Industrial Performance

Built with high-grade rubber and reinforced by tire cord and helical wire, this hose is engineered to withstand demanding industrial environments. Its round shape and sturdy MS flanged connections provide secure fittings, making it ideal for high-volume cement transfer and pneumatic applications in RMC and batching plants. The hose handles continuous operations and resists wear, ensuring longevity and minimal maintenance.

Optimized for Versatile Cement Handling

Whether it's transferring materials within cement factories, loading and unloading trucks, or spraying grout for infrastructure projects, this hose is crafted to handle varying operational requirements. It efficiently accommodates cement, fly ash, sand, and other powders between silos, hoppers, and mixers, making it a versatile solution for the construction and ready-mix concrete industry.

FAQ's of Cement Feeding Rubber Hose:

Q: How is the Cement Feeding Rubber Hose typically used in cement and construction industries?

A: This hose is primarily used for conveying and feeding cement and powders in batching plants, cement factories, and pneumatic conveying systems. It's also employed for truck and bulker loading/unloading, as well as spraying cement grout in dams, bridges, and infrastructure projects.Q: What features make this hose suitable for pneumatic conveying systems?

A: The hose's rubber construction reinforced with tire cord and helical wire provides excellent flexibility and strength. Its temperature resistance up to 70C and pressure tolerance of 10 kgf/m2 make it ideal for pneumatic material transfer in RMC and industrial plants.Q: When should I consider replacing the hose?

A: Replacement is recommended if the hose shows signs of excessive wear, leaks, or loss of flexibility, even though it comes with a 6-month warranty. Regular inspection ensures safe operation and minimizes downtime in industrial settings.Q: Where can this cement feeding hose be installed within a plant?

A: It is versatile for installation between silos, hoppers, mixers, and connecting bulker trucks for loading or unloading materials. It is suitable for use in batching plants, cement factories, and across various industrial transfer points.Q: What is the connection process for installing this hose?

A: The hose is equipped with MS flange connections as per ASA 150# standards, allowing secure and straightforward bolted installation to pipes, tanks, or equipment compatible with this flange size.Q: What are the main benefits of using this rubber hose over alternatives?

A: This hose offers superior abrasion resistance, reliable durability, and flexibility, making it well-suited for repetitive cement and powder handling. Its reinforced design reduces risks of rupture and operational failures in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Feeding Rubber Hose Category

Cement Feeding Rubber Hose

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

Hardness : 60

Material : Rubber

Temperature : 70 Celsius (oC)

Shape : Round

Cement Feeding Rubber Hose with Fixed Flange

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

Hardness : 605 Shore A

Material : Other, Natural/Synthetic Rubber

Temperature : 30C to +80C

Shape : Straight

Silo Rubber Hose

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

Hardness : 65 5 Shore A

Material : Other, Blend of natural and synthetic rubber

Temperature : 30C to +70C

Shape : Round / Cylindrical

Lay Flat Rubber Hose

Price 3500.0 INR / Meter

Minimum Order Quantity : 1 Meter

Hardness : 65 5 Shore A

Material : Other, Synthetic Rubber

Temperature : 20C to +80C

Shape : Flat when not in use

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS