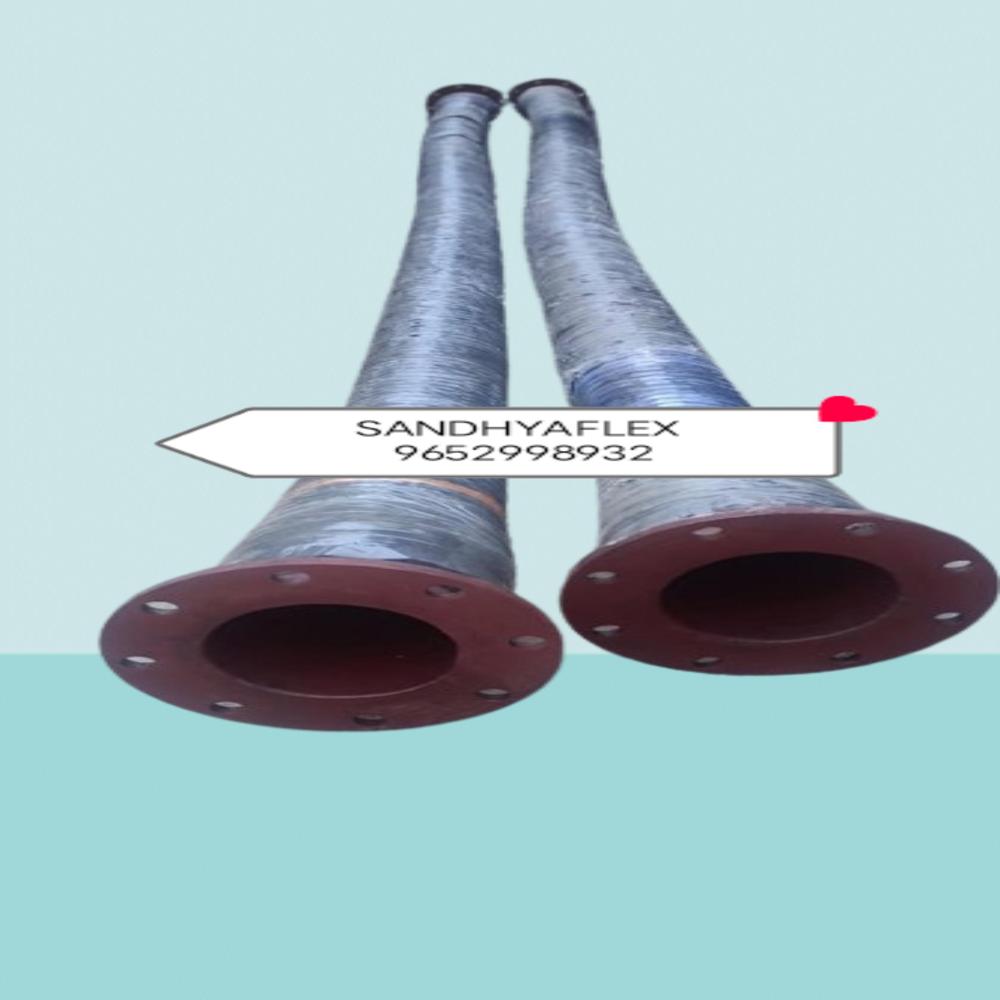

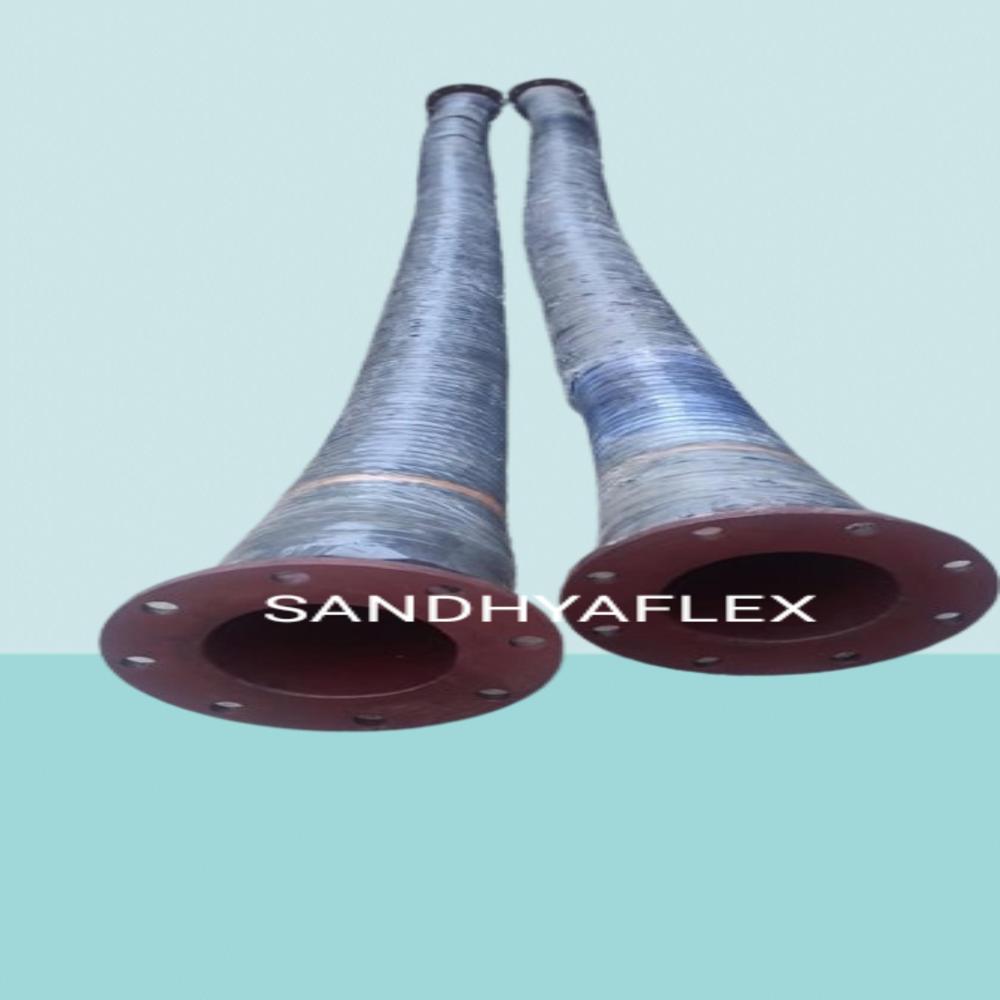

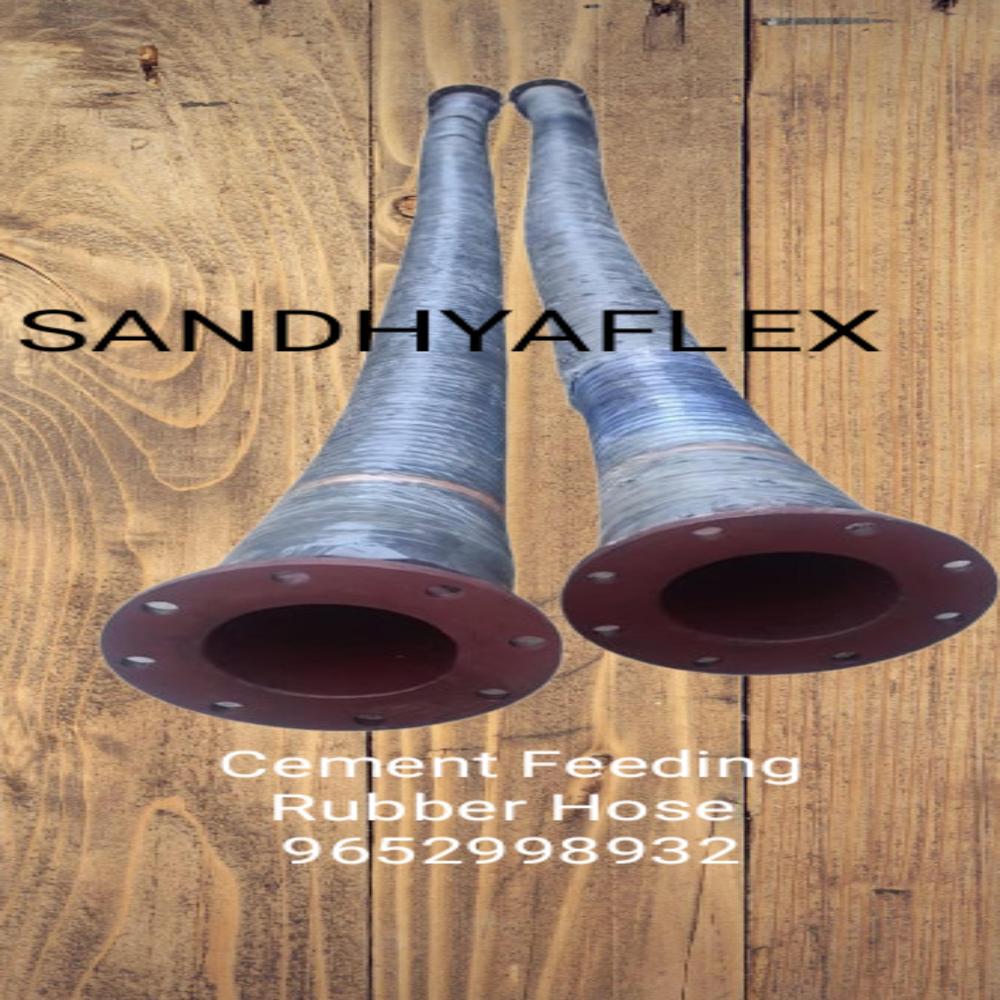

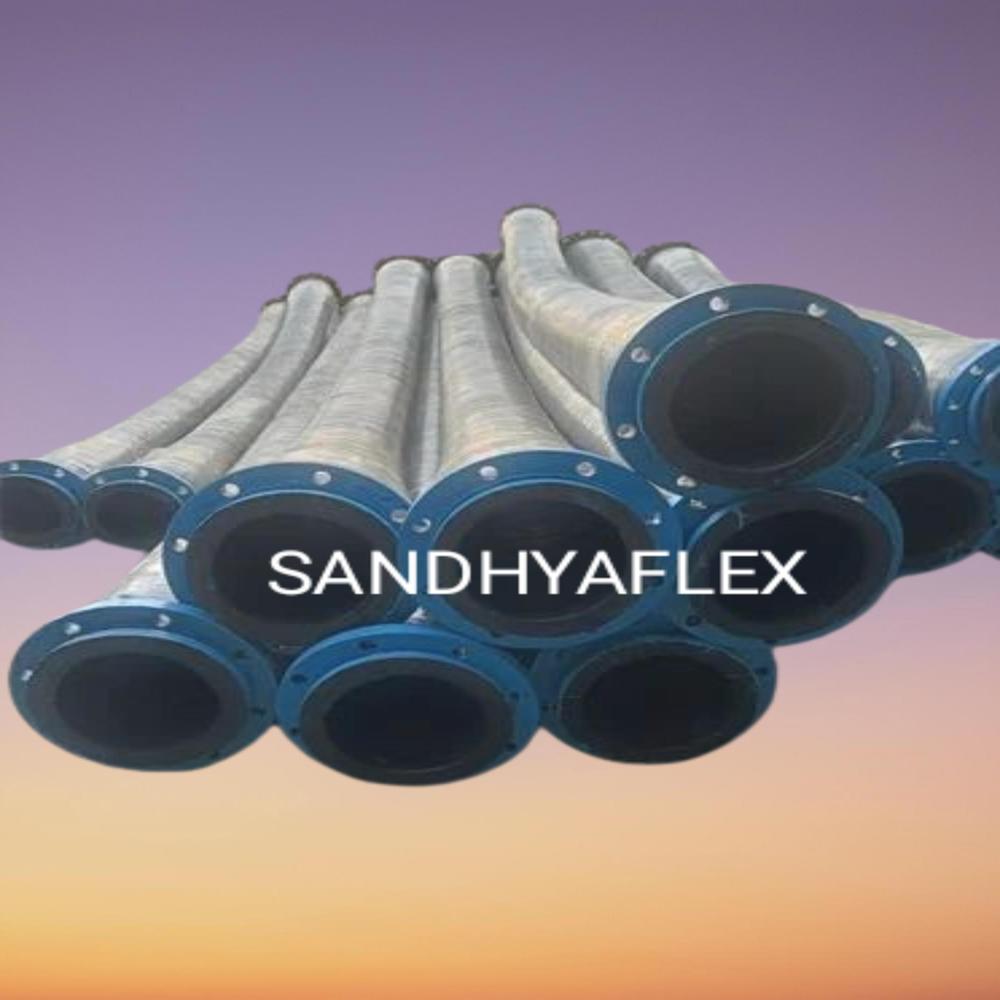

Cement Feeding Rubber Hose

Price 1600.0 INR/ Meter

Cement Feeding Rubber Hose Specification

- Shape

- Round

- Reinforcement

- High tensile textile cords with helical wire

- Cover

- Abrasion resistant synthetic rubber

- Medium

- Cement/Slurry

- Hardness

- 65 5 Shore A

- Connection Type

- Flanged/Plain End

- Material

- Synthetic Rubber

- Temperature

- -30C to +80C

- Pressure

- Up to 10 Bar

- Inside Diameter

- 51 mm to 152 mm

- Outside Diameter

- 64 mm to 165 mm

- Weight

- Variable as per dimensions

- Colour

- Black or as specified

- Length

- Up to 10 meters

- Application

- Used for bulk material transfer in construction, mining and concrete industries

- Surface Finish

- Smooth

- Standard

- IS: 13070 / International Standards

- Bending Radius

- 10 x D (where D is inside diameter)

- End Fittings

- MS Flanges as per client specification

- Working Environment

- Outdoor/Industrial settings

- Burst Pressure

- 3 times working pressure

About Cement Feeding Rubber Hose

Of course! Here's a clear and professional explanation of the Use and Application of Cement Feeding Rubber Hose:

Use and Application of Cement Feeding Rubber Hose

1. Use:

-

Cement Feeding Rubber Hose is specifically designed to transfer dry bulk materials such as cement, lime, fly ash, and other abrasive powders.

-

It is a high-pressure, heavy-duty hose used to feed dry materials from storage silos to transport vehicles like bulk tankers, or to feed cement into batching plants and construction equipment.

2. Applications:

-

Pneumatic Cement Transfer:

Used to transfer cement under air pressure from bulkers to silos at construction sites, RMC (Ready Mix Concrete) plants, and precast factories. -

Fly Ash Handling:

Used for transferring fly ash from tankers to storage silos. -

Concrete Batching Plants:

Connects silos to hoppers and feeding systems in RMC and concrete production units. -

Construction Sites:

Feeds cement, lime, or fine powders into construction mixers, pumps, and machines. -

Industrial Material Handling:

Used in industries handling fine dry materials that are abrasive in nature (cement, powdered chemicals, minerals, etc.).

3. Key Characteristics:

-

Heavy-duty construction with abrasion-resistant rubber lining.

-

High working pressure to withstand pneumatic conveying systems (typically 1015 Bar).

-

Flexible for easy installation and handling.

-

Reinforced with high-strength textile plies or steel wire helix (for added durability and pressure resistance).

4. Benefits:

-

Resistant to abrasion, tearing, and impact.

-

Designed for long service life even in tough site conditions.

-

Withstands high air pressures used in cement bulker unloading operations.

-

Available in different sizes (typically from 2", 3", 4" inner diameters) and lengths (like 3 meters, 6 meters).

Summary:

Cement Feeding Rubber Hose is essential for smooth, safe, and efficient bulk cement handling operations whether on a construction site, RMC plant, or industrial silo.

Would you also like a typical technical specification sheet (TDS) or a layout showing how the hose is connected between the bulker and silo?

It could be helpful if you're preparing a project, quotation, or product catalog!

Superior Construction for Industrial Demands

Built with abrasion-resistant synthetic rubber and reinforced high tensile textile cords, this hose is ideal for the rigorous demands of bulk cement and slurry transfer. The incorporation of helical wire ensures enhanced strength and flexibility, making it suitable for continual use in outdoor and industrial environments.

Versatile Design and Flexible Applications

Offered in a range of inside diameters from 51 mm to 152 mm, and customizable lengths, this hose adapts easily to various onsite requirements. Users can select from MS flanged ends or plain ends based on client specifications, ensuring compatibility with existing equipment and infrastructure.

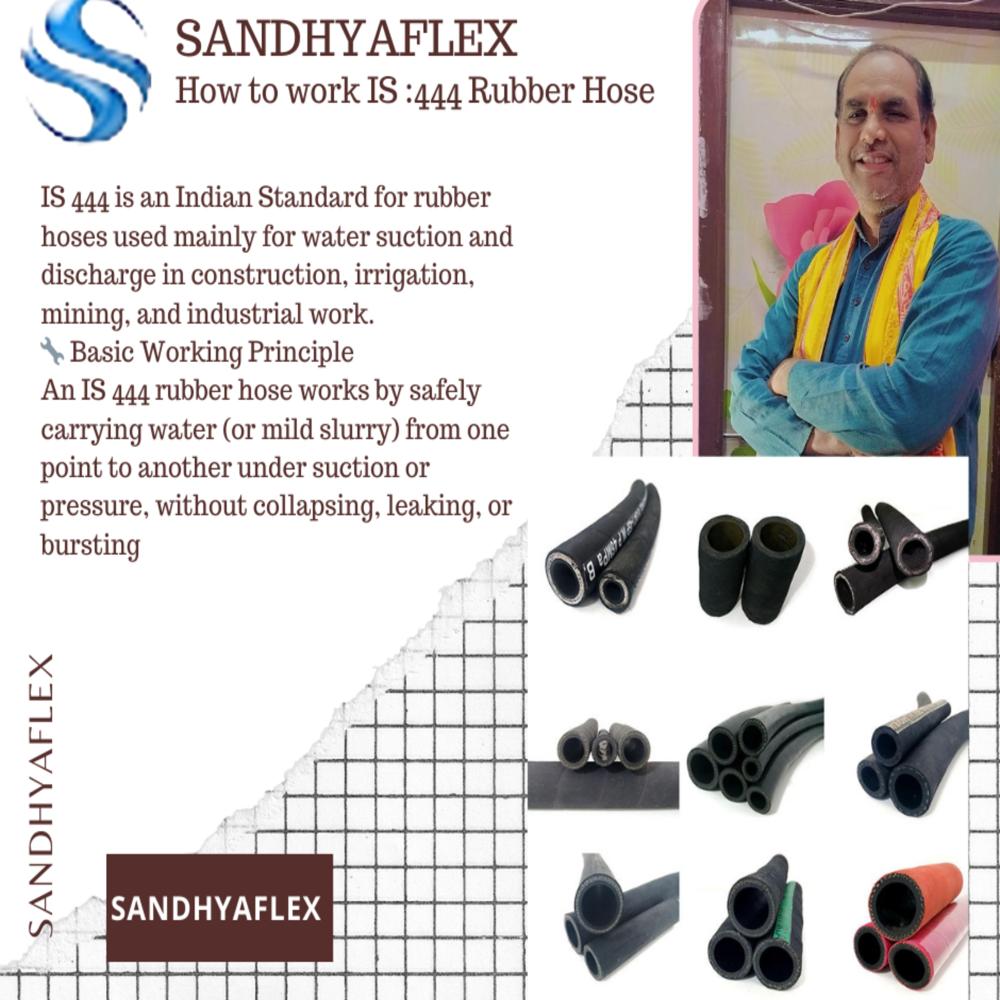

FAQ's of Cement Feeding Rubber Hose:

Q: How is the Cement Feeding Rubber Hose installed in construction or mining operations?

A: The hose can be installed using either MS flanged or plain ends, which connect seamlessly with existing pipeline systems and equipment as per client specifications. Its flexible design and smooth surface finish facilitate easy alignment and setup during on-site installation.Q: What types of materials can be conveyed through this hose?

A: This hose is engineered to transfer cement, slurry, and other bulk materials commonly found in the construction, mining, and concrete industries. Its synthetic rubber material and robust reinforcement ensure safe and efficient conveying of abrasive and dense media.Q: Where is this rubber hose best suited for application?

A: It is ideal for outdoor and industrial settings, such as construction sites, mining locations, and concrete mixing plants, where heavy-duty material transfer is required under variable environmental conditions.Q: What makes this hose compliant with safety and international standards?

A: The hose adheres to IS: 13070 and other recognized international standards, ensuring safe operation up to pressures three times the working pressure and reliable performance across a wide temperature range.Q: How does the hose benefit users in terms of maintenance and longevity?

A: The abrasion-resistant synthetic rubber cover and reinforced construction minimize wear, reducing the need for frequent maintenance and extending the hose's operational life in demanding industrial applications.Q: What is the process to customize the hose according to client requirements?

A: Manufacturers offer customization of length, diameter, end fittings, and even color options according to client specifications, ensuring the hose integrates with specific system requirements and delivers optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Feeding Rubber Hose Category

Air Rubber Hose

Price 90.0 INR / Meter

Minimum Order Quantity : 1 Meter

Temperature : 70 Celsius (oC)

Cover : Rubber

Shape : Round

Reinforcement : Tire Cord and Helicles Wire

Fly Ash Rubber Hose

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

Temperature : 70 Celsius (oC)

Cover : Rubber

Shape : Round

Reinforcement : Tire Chord and MS Helicles wire

Plain Top Rubber Hoser

Price 1600.0 INR / Meter

Minimum Order Quantity : 1 Meter

Temperature : 20C to +70C

Cover : Smooth, Black Rubber

Shape : Round

Reinforcement : Synthetic Textile

Fly Ash Rubber Rubber

Price 2100.0 INR / Meter

Minimum Order Quantity : 1 Meter

Temperature : 30C to +120C

Cover : Abrasion, weather, and ozone resistant rubber

Shape : Round

Reinforcement : High tensile synthetic plies with steel wire helix

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free