Cement Feeding Rubber Hose

Price 1600.0 INR/ Meter

Cement Feeding Rubber Hose Specification

- Hardness

- 55 to 60

- Medium

- Air

- Shape

- Round

- Reinforcement

- The **reinforcement in Sandhyaflex Cement Feeding Rubber Hose** is designed to provide **strength, flexibility, and durability**, especially when handling **abrasive materials like cement and concrete**. Here s a detailed breakdown: --- ### **1. Reinforcement Structure** * **High-tensile synthetic textile cords** * Multiple layers of synthetic cords are embedded in the rubber plies. * Provides **tensile strength** and prevents elongation under pressure. * **Steel Wire Helices (in some sizes)** * Helically wound steel wires may be incorporated to resist **vacuum collapse** during suction applications. * Ensures the hose **maintains shape under negative pressure**. * **Rubber Plies** * Layers of natural and synthetic rubber hold the cords/wires in place. * Enhances **abrasion resistance** and **pressure endurance**. * **Electrical Continuity Wire (optional)** * A thin copper wire may be included between plies to **dissipate static electricity** when transferring cement powders. --- ### **2. Benefits of Reinforcement** * **Pressure Resistance:** Withstands working pressures typically up to **10 bar** and burst pressures higher. * **Flexibility:** Despite multiple reinforcement layers, the hose remains **easy to handle and bend**. * **Durability:** Resistant to **abrasion from cement, fly ash, and other powders**. * **Vacuum Performance:** Can handle **suction during cement feeding** without collapsing. --- In short, the **reinforcement of Sandhyaflex Cement Feeding Rubber Hose** is a combination of **synthetic cords, optional steel wire helix, and rubber plies** to ensure **high strength, flexibility, and long life** under heavy-duty cement handling conditions. If you want, I can make a **diagram showing the reinforcement layers of this hose** for a clear visual understanding. Do you want me to do that?

- Cover

- The **cover of a Sandhyaflex Cement Feeding Rubber Hose** is specifically designed to **protect the hose from external damage, abrasion, and environmental factors**, while ensuring safety during cement handling. Here s a detailed breakdown: --- ### **1. Material** * Made from **high-quality synthetic rubber compounds**, often blended with natural rubber. * **Abrasion-resistant** to withstand contact with rough surfaces, equipment, and cement particles. * **Weather and UV resistant**, suitable for outdoor use at construction sites. * Resistant to **oil, grease, and chemical splashes** that may be present on construction or industrial sites. --- ### **2. Surface and Design** * **Cloth-marked or smooth finish** to reduce friction and wear during operation. * Flexible enough to allow **easy handling and bending** without damaging the hose. * Designed to **prevent ingress of dirt or water** that could compromise hose performance. --- ### **3. Additional Features** * Some hoses include **embedded copper wire** for **electrical continuity**, preventing static charge buildup when transferring dry cement or powders. * The cover works in tandem with the inner lining and reinforcement to provide **overall hose durability and long service life**. --- ### ** Key Benefits** * **Enhanced Durability:** Protects the hose against mechanical wear and environmental factors. * **Safety:** Reduces risk of hose failure and static buildup during cement transfer. * **Versatility:** Suitable for **construction sites, cement plants, and industrial applications**. --- If you want, I can make a **full diagram showing the layers of Sandhyaflex Cement Feeding Rubber Hose**, including **lining, reinforcement, and cover**, so you can see it visually. This is often very helpful for technical understanding. Do you want me to make that diagram?

- Connection Type

- [](https://www.sandhyaflex.com/slurry-and-mud-rubber-hose.html?utm_source=chatgpt.com) The **SANDHYAFLEX Slurry Rubber Hose** is designed with specific connection types to ensure durability and efficiency in handling abrasive materials. ### Connection Types 1. **Built-in Flange Connection** * **Standard**: Most commonly, these hoses come with built-in flanges made of **Mild Steel (MS)**, conforming to **ASA 150# ANSI 16.5 Drilled and DIN specifications**. * **Applications**: Ideal for high-pressure slurry transport in industries like mining, construction, and dredging. * **Sizes**: Available in diameters ranging from **6 inches (150mm) to 10 inches (250mm)**, with lengths up to **15 meters**. ([Sandhya Enterprises][1]) 2. **Camlock Fitting** * **Features**: Some hoses are equipped with **Camlock fittings**, which are quick-connect couplings made from materials like **aluminum, stainless steel, or brass**. * **Advantages**: These fittings allow for rapid connection and disconnection, making them suitable for temporary setups or applications requiring frequent hose changes. * **Specifications**: Typically, these hoses have a **working pressure of 25 bar** and are constructed with **6 layers** for enhanced durability. ([sandhyaenterprises.co.in][2]) 3. **Dredge Delivery Hose** * **Design**: For specialized applications like dredging, hoses are manufactured with **rubberized built-in steel/rubber flanges**. * **Reinforcement**: These hoses are reinforced with **high-tensile steel wires** and are designed to handle extreme pressures. * **Pressure Ratings**: They are tested for a **proof pressure of 20 kg/cm **, with a burst pressure designed to be **four times the working pressure**. ([Sandhya Enterprises][3]) ### Summary | Connection Type | Material | Pressure Rating | Common Applications | | -------------------- | ------------------------ | --------------- | ------------------------------------- | | Built-in Flange | MS (Mild Steel) | Up to 25 bar | Mining, construction, dredging | | Camlock Fitting | Aluminum/Stainless Steel | Up to 25 bar | Temporary setups, frequent changes | | Dredge Delivery Hose | Rubberized Steel Flanges | High Pressure | Dredging, heavy-duty slurry transport | Each connection type is tailored to specific operational needs, ensuring optimal performance and safety in various industrial applications. If you need further details or assistance in selecting the appropriate hose for your application, feel free to ask! [1]: https://www.sandhyaflex.com/slurry-and-mud-rubber-hose.html?utm_source=chatgpt.com "Slurry and Mud Rubber Hose - Sandhya Enterprises" [2]: https://www.sandhyaenterprises.co.in/marine-rubber-hose.html?utm_source=chatgpt.com "Marine Rubber Hose - ASA 150 Class Flange Fitting ..." [3]: https://www.sandhyaflex.com/dredge-hose.html?utm_source=chatgpt.com "Dredge Delivery Rubber Hose - Sandhya Enterprises"

- Usage

- The **SANDHYAFLEX Cement Feeding Rubber Hose** is specifically designed for **handling dry bulk materials like cement, fly ash, and powders** in construction and industrial applications. Its **robust construction, abrasion resistance, and flexibility** make it suitable for various demanding operations. Here s a detailed breakdown of its usages: --- ### **1. Construction Sites** * **Cement Grouting & Pumping:** Transfers cement from mixing trucks to pumping machines or spraying equipment. * **Bridges, Roads, and Buildings:** Delivers cement for structural work, especially in high-rise or difficult-to-access areas. * **Dam & Tunnel Projects:** Enables pumping of cement grout or concrete in large-scale projects. --- ### **2. Cement & Concrete Plants** * **Bulk Material Transfer:** Moves **cement, fly ash, and other powders** from storage silos to mixing units. * **Pneumatic Conveying:** Works efficiently with air-assisted systems for conveying cement powders. --- ### **3. Mining & Industrial Applications** * **Abrasive Material Handling:** Can transport **fly ash, sand, or other abrasive powders** safely. * **Dust-Free Operation:** The smooth inner lining ensures minimal material loss and dust emission. --- ### **4. Specialized Applications** * **Hilly Terrains:** Flexible enough for use in areas with challenging terrain or space constraints. * **Vacuum Applications:** Reinforced hoses can handle suction for cement feeding without collapsing. * **Temporary Setups:** Can be connected quickly using **flanges or Camlock fittings** for temporary material transfer. --- ### ** Key Advantages in Use** * **Abrasion Resistance:** Withstands wear from dry powders like cement and fly ash. * **Flexibility & Ease of Handling:** Can be bent or moved easily, even in tight spaces. * **Pressure & Vacuum Tolerance:** Suitable for pumping and suction operations. * **Safety:** Embedded copper wire ensures **electrical continuity**, preventing static buildup during material transfer. --- If you want, I can create a **compact table summarizing the product, its uses, reinforcement, cover, and connection types** for all Sandhyaflex hoses. This gives a **quick glance comparison** for industrial selection. Do you want me to make that table?

- Material

- Rubber

- Size

- 100NB

- Height

- 124 Millimeter (mm)

- Temperature

- 80 Celsius (oC)

- Pressure

- 10 Bar

- Product Type

- [](https://www.sandhyaflex.com/cement-fedding-rubber-hose.html?utm_source=chatgpt.com) The **Sandhyaflex Cement Feeding Rubber Hose** is a **heavy-duty industrial hose** designed for the efficient and safe transfer of **cement, fly ash, and other dry bulk materials** in construction and industrial applications. --- ### Product Type: Heavy-Duty Cement Feeding Rubber Hose **Key Features:** * **Lining:** Manufactured from a blend of **natural and synthetic rubber compounds**, forming a **thick, homogeneous, and seamless tube**. This construction provides excellent **abrasion resistance** without air blisters, porosity, or other flaws. * **Reinforcement:** Incorporates **multiple plies of high-tensile synthetic textile cords**, providing strength and flexibility. Some variants include **helical steel wire** embedded in the layers to enhance durability and resistance to pressure. * **Cover:** Made from a **weather- and abrasion-resistant rubber compound** with a cloth-marked surface, offering protection against environmental factors and mechanical wear. * **Electrical Continuity:** A **copper wire strand** is embedded within the hose to ensure **electrical continuity**, preventing the buildup of static electricity during the transfer of dry materials. --- ### Specifications * **Size Range:** Available in diameters from **3" (75mm) to 16" (400mm)**. * **Length:** Standard lengths range from **5 meters to 15 meters**, depending on the diameter. * **Working Pressure:** Typically rated at **10 bar (10 kg/cm )**. * **Proof Pressure:** Approximately **1.5 times the working pressure**. * **Burst Pressure:** Approximately **three times the working pressure**. * **Temperature Range:** Suitable for use in temperatures ranging from **-10 C to 100 C**. --- ### End Connections * **Built-in Flange:** Equipped with **Mild Steel (MS) flanges** conforming to **ASA 150# ANSI 16.5 Drilled** standards, facilitating secure and leak-proof connections. * **Camlock Fittings:** Some variants feature **Camlock fittings**, allowing for quick and easy connection and disconnection, ideal for applications requiring frequent hose changes. --- ### Applications * **Construction Sites:** Used for spraying **cement grout** in building projects, dams, bridges, and roads, especially in hilly terrains. * **Industrial Applications:** Suitable for transferring **cement, fly ash, and other dry bulk materials** in plants and factories. * **Mining Operations:** Facilitates the movement of **abrasive slurries** and materials in mining sites. --- For more detailed information or to place an order, you can visit the official [Sandhyaflex Cement Feeding Rubber Hose page](https://www.sandhyaflex.com/cement-fedding-rubber-hose.html). If you need assistance selecting the appropriate hose size or have further questions, feel free to ask!

- Inside Diameter

- 100 Millimeter (mm)

- Weight

- 5 Kilograms (kg)

- Outside Diameter

- 125 Millimeter (mm)

- Color

- Color

- Length

- 6 Meter (m)

- Width

- 124 Millimeter (mm)

- Warranty

- 6

Cement Feeding Rubber Hose Trade Information

- Minimum Order Quantity

- 1 Meter

- Delivery Time

- 7 Days

About Cement Feeding Rubber Hose

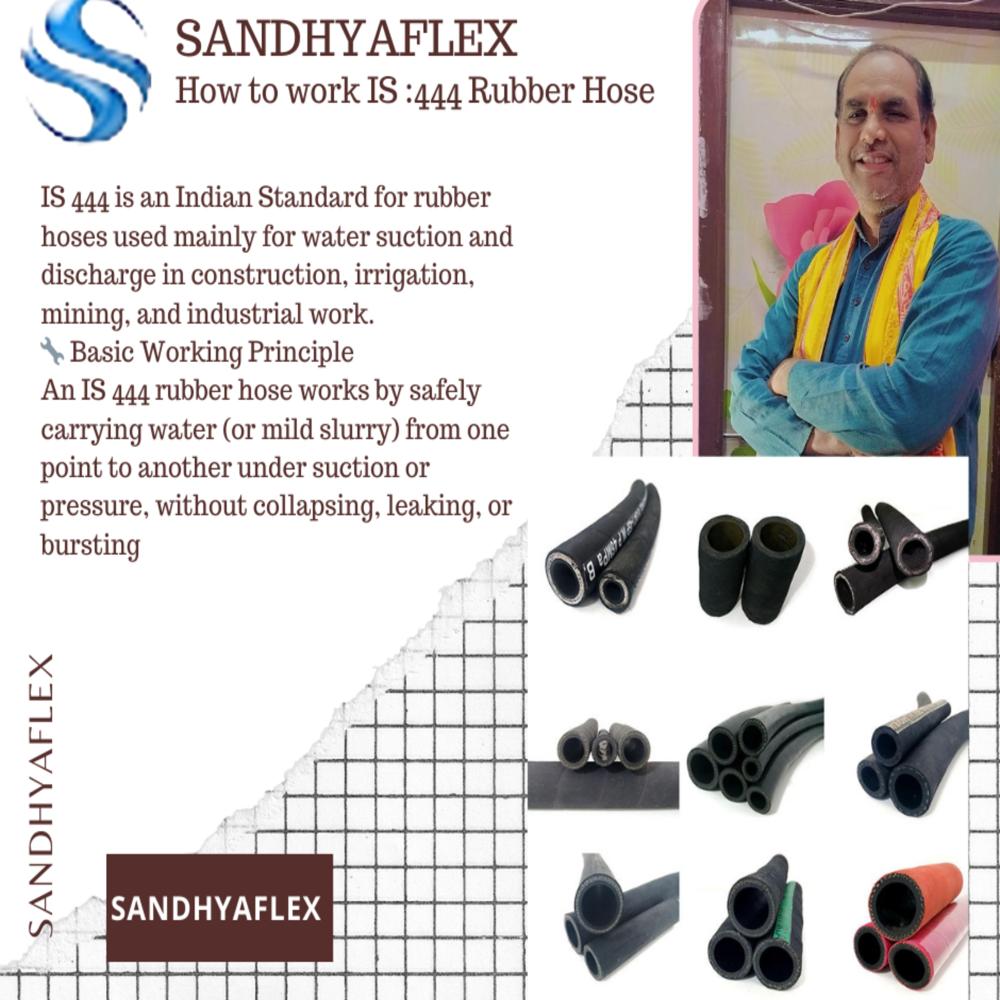

The SANDHYAFLEX Cement Feeding Rubber Hose is engineered for the efficient and safe transfer of cement, concrete, and other abrasive materials in construction and industrial applications. Here's an overview of its specifications and features:

Key Specifications

-

Inner Diameter (ID): Available in sizes ranging from 3" to 16" (75 mm to 400 mm).

-

Length: Typically available in 5-meter sections, with maximum lengths up to 15 meters for smaller diameters.

-

Working Pressure: 10 bar (10 kg/cm).

-

Proof Pressure: 1.5 times the working pressure.

-

Burst Pressure: 3 times the working pressure.

-

Temperature Range: -10C to 150C.

-

Vacuum Resistance: Minimum 700 mmHg (0.9 bar).

-

Bending Radius: 10 times the inner diameter of the hose.

-

End Connections: Built-in flanges (MS or GI) as per ASA 150# standards.

Construction Features

-

Lining: Made from a blend of natural and synthetic rubber compounds, providing excellent abrasion resistance and a smooth bore.

-

Reinforcement: Multiple layers of high-tensile synthetic textile cords and steel wire helices embedded in rubber plies, ensuring strength and flexibility.

-

Cover: Cloth-marked synthetic rubber compound that is weather and abrasion-resistant.

-

Electrical Continuity: Incorporates a copper wire strand to ensure electrical continuity along the entire length of the hose.

Applications

-

Construction Sites: Used for spraying cement grout in building projects, dams, bridges, and roads, especially in hilly terrains.

-

Concrete Placement: Facilitates the controlled and precise delivery of cement or concrete from mixing trucks to desired locations.

-

Industrial Applications: Suitable for transporting sand, gravel, mud slurry, concrete slurry, and mining particles.

Available Sizes

| Diameter (ID) | Maximum Length |

|---|---|

| 3" (75 mm) | 15 meters |

| 4" (100 mm) | 15 meters |

| 5" (125 mm) | 15 meters |

| 6" (150 mm) | 15 meters |

| 8" (200 mm) | 6 meters |

| 10" (250 mm) | 6 meters |

| 12" (300 mm) | 6 meters |

| 14" (350 mm) | 5 meters |

| 16" (400 mm) | 5 meters |

For more detailed information or to place an order, you can visit the Sandhya Enterprises website.

If you need assistance selecting the appropriate hose size or have further questions, feel free to ask!

Tailored for Heavy-Duty Material Handling

Sandhyaflex Cement Feeding Rubber Hose is meticulously designed to withstand the rigors of transporting cement and abrasive powders. Its reinforced structure and flexible profile allow reliable performance under high pressure and variable temperatures, making it suitable for both pneumatic conveying and grouting operations in construction, mining, and industrial applications.

Superior Protection and Durability

The hose features a high-quality synthetic rubber cover that defends against abrasion, oil, chemicals, UV exposure, and rough handling. Its construction ensures both longevity and operational safety, minimizing downtime from hose failures and optimizing productivity at busy job sites.

Engineered for Versatility and Safety

With integrated reinforcement-textile cords, optional steel wire, and electrical continuity wire-the hose maintains its integrity even during vacuum applications and material transfer where static buildup could pose risks. Its adaptability enables quick installation through flange or Camlock connections, serving diverse industrial needs with ease.

FAQ's of Cement Feeding Rubber Hose:

Q: How does the Sandhyaflex Cement Feeding Rubber Hose achieve both flexibility and strength?

A: The hose incorporates high-tensile synthetic textile cords and, in certain models, helically wound steel wires within the rubber layers. This reinforcement grants the hose flexibility for easy handling while delivering robust strength to withstand working pressures up to 10 bar and prevent elongation or collapse during use.Q: What makes the outer cover of this hose particularly resilient in harsh environments?

A: The outer cover is crafted from synthetic rubber blends that are resistant to abrasion, weather, chemicals, oil, and UV radiation. This ensures the hose remains intact even when exposed to rough surfaces, frequent handling, or outdoor use at construction and industrial sites.Q: When is it necessary to use a hose with an electrical continuity wire?

A: An electrical continuity wire is recommended when transferring dry materials like cement or powders in pneumatic systems, which may generate static electricity. The embedded copper wire safely dissipates static charge, minimizing the risk of sparks and ensuring operator and workplace safety.Q: Where is this cement feeding hose commonly used?

A: It is primarily employed in construction sites, cement plants, tunneling and dam projects, and other locations requiring bulk transfer or pneumatic conveyance of dry materials. Its robust design also suits mining, industrial, and temporary setups requiring versatile and durable hoses.Q: What connection types are available for the Sandhyaflex Cement Feeding Rubber Hose, and how do they enhance usability?

A: The hose is available with built-in steel flange connections or quick-connect Camlock fittings. Flange connections suit permanent, high-pressure installations, while Camlocks enable speedy attachment and detachment for temporary or frequently modified systems, reducing operational downtime.Q: How should this hose be maintained for optimal longevity?

A: Regularly inspect the hose for signs of external wear, check fittings and flanges for tightness, and ensure the hose is not kinked or excessively bent during use. Store in a dry location away from direct sunlight and corrosive materials to extend its service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Feeding Rubber Hose Category

Bulkar Cement Loading and Unloading Rubber HOse

Price 2100.0 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : Round

Connection Type : MS Flange

Hardness : 60 Shore A

Medium : Air

Air Rubber Hose

Price 90.0 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : Round

Connection Type : Flange

Hardness : 60

Medium : Air

Flay Ash Rubber Hose

Price 2400.0 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : Round

Connection Type : Flanged

Hardness : 605 Shore A

Medium : Other, Fly Ash, Slurry, Abrasive Materials

Cement Air Rubber Hose

Price 1200.0 INR / Meter

Minimum Order Quantity : 1 Meter

Shape : Round

Connection Type : Plain or Flanged Ends

Hardness : 5565 Shore A

Medium : Other, Air, Cement, Abrasive Dry Materials

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free