VIBRATING SCREEN RUBBER BEADING

Price 150.00 INR/ Meter

VIBRATING SCREEN RUBBER BEADING Specification

- Ash %

- Yes

- Surface Finish

- Polished

- Material

- Rubber

- Color

- Gray

- Usage & Applications

- HIGH QUALITY RUBBER Color

- Thickness

- 10 Millimeter (mm)

- Size

- Standerd

About VIBRATING SCREEN RUBBER BEADING

Vibrating Screen Rubber Beading is a critical component in the screening and mining industry. Heres a quick overview to help you out:

What is Vibrating Screen Rubber Beading?

Rubber beading is a flexible stripusually made from natural or synthetic rubberused in vibrating screens to:

-

Provide cushioning between the screen mesh and the screen frame

-

Absorb vibration and impact

-

Reduce noise

-

Prevent metal-to-metal contact, increasing the life of the mesh

-

Ensure tight and secure clamping of the screen cloth

Common Specifications

-

Material: Natural Rubber, EPDM, or Neoprene (depending on heat/oil/weather resistance needs)

-

Shape: U-type (most common), also available in C-type, L-type, etc.

-

Size: Varies depending on screen frame and mesh sizecommon U-type sizes include:

-

5mm, 6mm, 10mm groove widths

-

25mm50mm height range

-

-

Hardness: Typically 6070 Shore A for optimal flexibility + durability

Installation Tips

-

Clean the frame thoroughly before applying.

-

Fit the beading along the edge of the screen frame.

-

Insert the mesh into the groove.

-

Use clamps or fasteners to hold it all tightly in place.

Benefits

-

Increases screen mesh life

-

Reduces maintenance downtime

-

Improves screening efficiency

-

Dampens vibration and noise

Let me know if you need help choosing the right size, finding a supplier, or even drafting a purchase spec sheet for it!

Superior Quality and Versatility

Crafted from premium rubber and finished with a polished surface, this beading stands out for its durability and adaptability. Its standard size and 10 mm thickness make it suitable for most vibrating screen assemblies, ensuring compatibility and ease of use across a broad range of industrial sectors.

Comprehensive Distribution Across India

Whether you need a small batch or bulk quantities, you can source Vibrating Screen Rubber Beading from a wide network of dealers, manufacturers, and wholesalers across India. Efficient supply chains ensure timely delivery, catering to various project scales and timelines.

FAQ's of VIBRATING SCREEN RUBBER BEADING:

Q: How is Vibrating Screen Rubber Beading used in industrial applications?

A: Vibrating Screen Rubber Beading is primarily used to protect the edges of vibrating screens, preventing abrasion and providing a secure, cushioned seal between the screen frame and mesh. This prolongs the lifespan of the equipment and ensures efficient operation in harsh industrial environments.Q: What process is involved in manufacturing this rubber beading?

A: The rubber beading is produced through a molding process using high-quality rubber compounds, ensuring a polished surface finish and precise dimensions. The manufacturing process includes measuring the ash content to guarantee performance standards, followed by rigorous quality checks.Q: Where can I purchase Vibrating Screen Rubber Beading in India?

A: You can obtain this product from various channels across India, including dealers, manufacturers, suppliers, fabricators, producers, traders, retailers, and wholesalers. Most industrial supply companies will have it in stock or can arrange prompt delivery.Q: What are the benefits of using this particular rubber beading?

A: This beading offers superior durability, excellent sealing, and resistance to wear and tear. Its 10 mm thickness and premium quality ensure it withstands constant vibration, thus reducing maintenance costs and downtime.Q: When should Vibrating Screen Rubber Beading be replaced?

A: Replacement is recommended when you observe signs of wear such as cracks, hardening, or reduced elasticity. Regular inspection schedules help ensure the beading remains effective, preserving the integrity of your vibrating screens.Q: Does this beading come in colors other than gray?

A: The standard offering is gray. If custom colors are required for specific applications or aesthetics, you should consult with the manufacturer or supplier for possible options.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Products Category

DI pipe Gasket

Price 250.0 INR / Piece

Minimum Order Quantity : 1 Piece

Style : Ring type gasket, plain and socket options

Color : Black

Hardness : 70 5 Shore A

Product Type : DI pipe Gasket

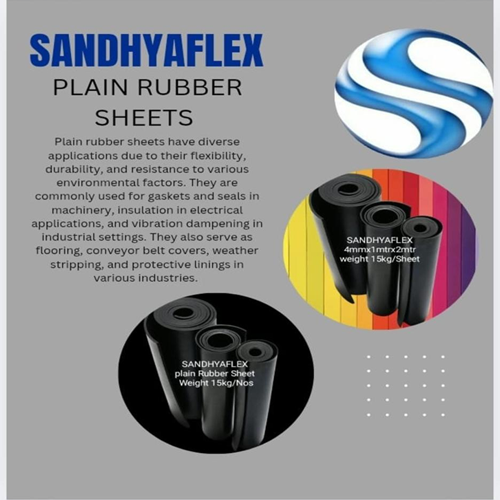

Plain Rubber Sheet

Price 55.0 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Style : Plain, Smooth

Color : Black

Hardness : 40 to 80 Shore A

Product Type : Plain Rubber Sheet

Cuttles Rubber Bearing

Price 2500.0 INR / Number

Minimum Order Quantity : 1 Number

Style : Cuttles

Color : Black

Hardness : 605 Shore A

Product Type : Rubber Bearing

Rubber Dock Bumper

Price 2165.0 INR / Number

Minimum Order Quantity : 1 Number

Style : Rectangular with reinforced mounting holes

Color : Black

Hardness : 70 5 Shore A

Product Type : Dock Bumper

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free