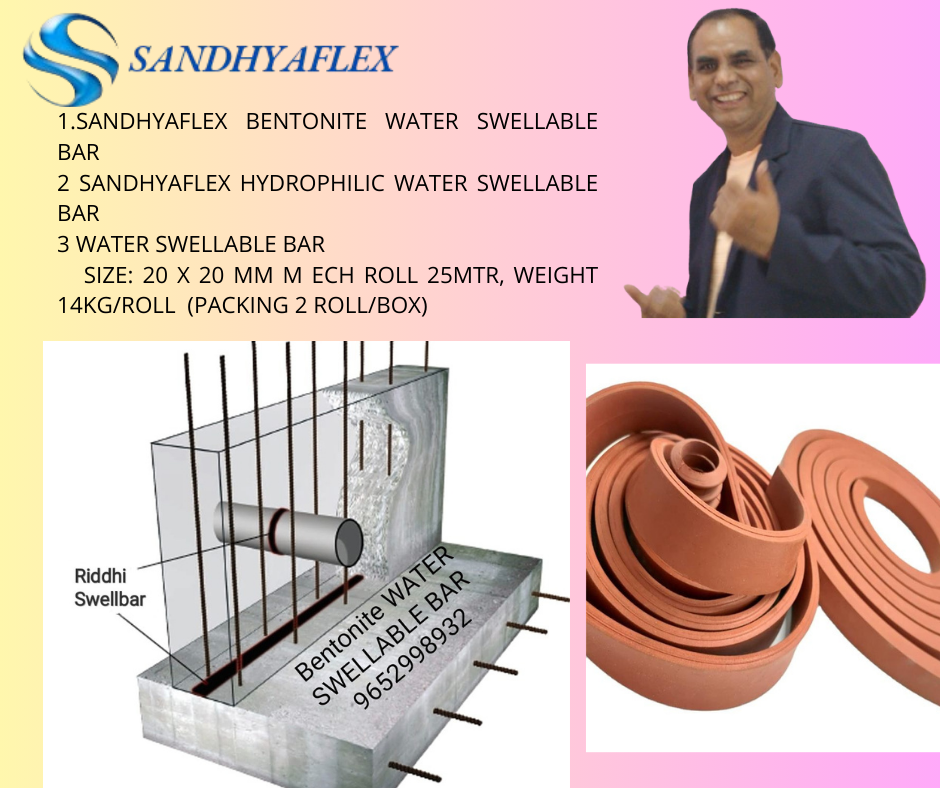

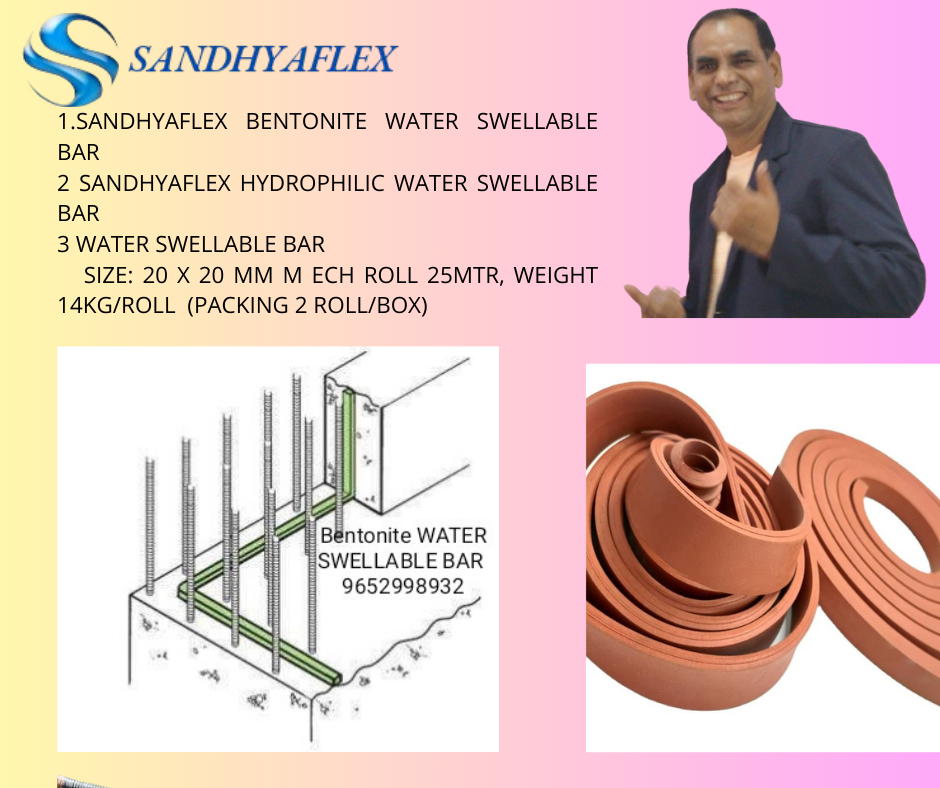

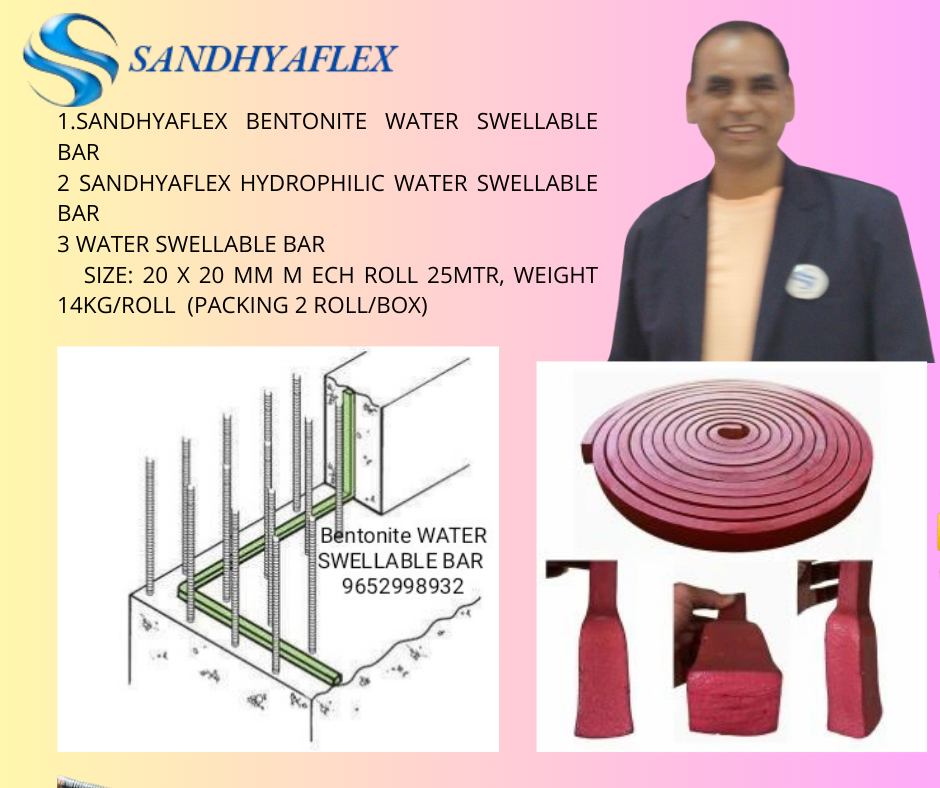

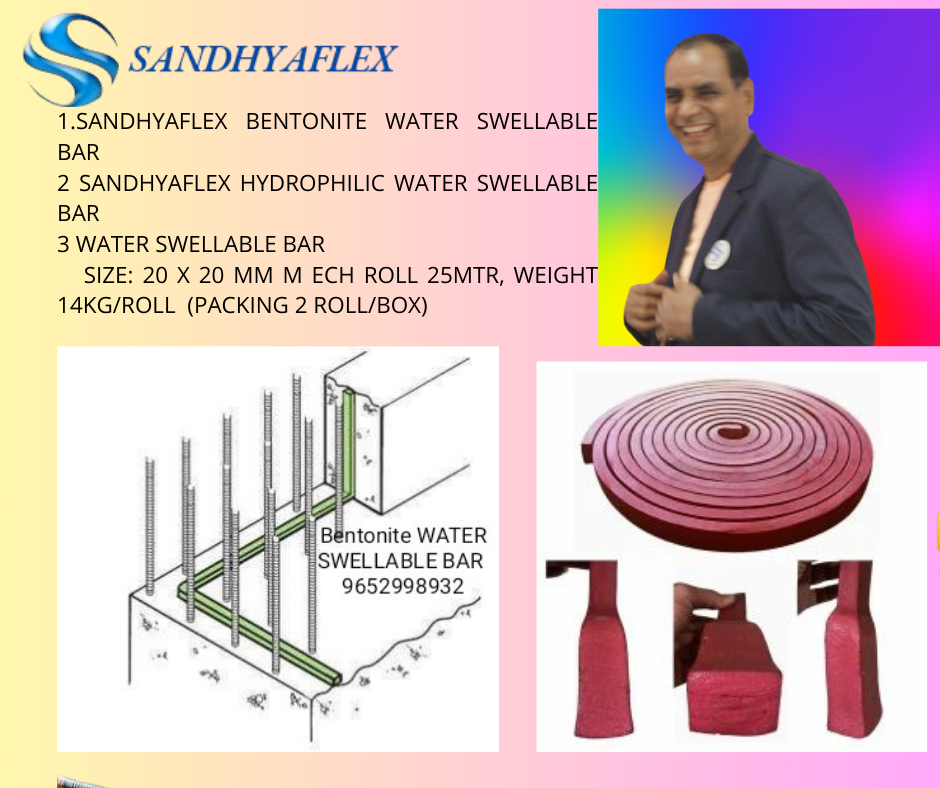

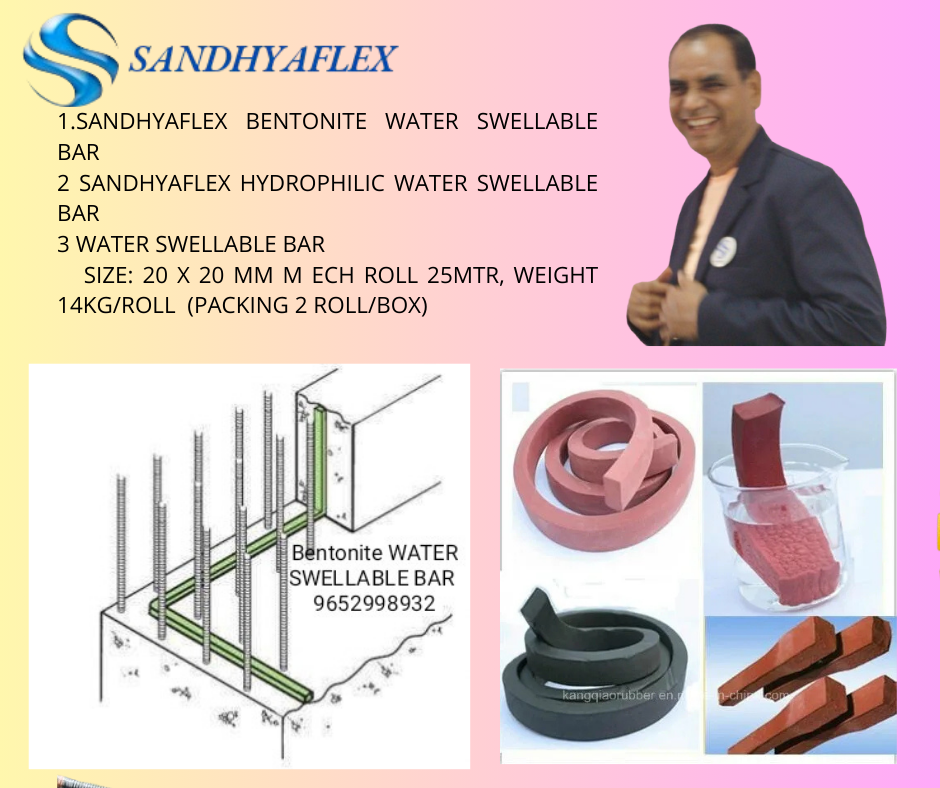

Premium Quality Bentonite Water Swellable Bar 20x25mm

Price 324.0 INR/ Meter

Premium Quality Bentonite Water Swellable Bar 20x25mm Specification

- Material

- Premium Quality Bentonite

- Type

- Swellable Bar

- Thickness

- 20x25mm

- Application

- Waterproofing in Construction, Tunnels, Basements, and Concrete Joints

- Hardness

- Medium to High

- Surface Treatment

- Smooth Finish

- Feature

- Highly Water Swellable, Non-toxic, Durable Bonding

About Premium Quality Bentonite Water Swellable Bar 20x25mm

A Bentonite Water Swellable Bar with dimensions 20mm x 25mm is similar to the 20x20mm version you previously mentioned, but with a slightly larger size. This type of bar is used for waterproofing and sealing joints or cracks in concrete structures, preventing water ingress by swelling when exposed to water.

Key Features of Bentonite Water Swellable Bar (20mm x 25mm):

-

Bentonite Composition:

-

Made from bentonite, a natural clay known for its excellent ability to absorb water and swell. This swelling action forms a seal that is impermeable to water, effectively preventing moisture from entering through the gaps or cracks in concrete.

-

-

Swelling Action:

-

The bentonite bar absorbs moisture when it comes into contact with water, causing it to expand. As the swelling continues, it creates a tight, long-lasting seal that can withstand varying water pressures and fluctuating conditions.

-

-

Durability and Flexibility:

-

These bars are highly durable and flexible, meaning they can adjust to slight movements in the structure without breaking the seal. This flexibility helps maintain an effective waterproofing barrier over time, even as the concrete undergoes expansion, contraction, or slight shifting.

-

-

Self-Activating:

-

Bentonite bars are self-activating, meaning they do not require additional maintenance or external activation after installation. Once in place, they automatically swell upon contact with water, providing continuous protection without the need for ongoing intervention.

-

-

Easy Installation:

-

These bars are typically installed during the construction process, either in formwork or as part of the joint or crack filling. They are generally embedded within the concrete slab or placed around pipe penetrations to ensure that they remain in place.

-

Dimensions Breakdown:

-

20mm (Width): The width of 20mm allows the bar to seal a joint effectively by providing enough material for adequate swelling.

-

25mm (Height/Thickness): With a thickness of 25mm, the bar has a larger volume for absorbing water and swelling, which ensures that it forms a more robust barrier, especially for joints exposed to higher water pressure.

Common Applications:

-

Construction Joints: These bars are often used in joints between different pours of concrete, ensuring that water does not seep through critical areas where two concrete sections meet.

-

Underground and Subterranean Structures: Ideal for tunnels, basements, or any underground facility that is subjected to groundwater or high moisture levels.

-

Water Retaining Structures: These bars are commonly used in dams, reservoirs, water treatment plants, and swimming pools where a strong waterproof barrier is required to prevent water leakage.

-

Pipe Penetrations: Used around pipes and other utility penetrations to prevent water from leaking around the area where the pipe passes through concrete.

Advantages:

-

Long-Lasting Waterproofing: The swelling action ensures that the barrier remains effective even with changes in water pressure, providing long-term protection against water ingress.

-

Natural Material: Bentonite is a natural clay, making the product environmentally friendly compared to synthetic alternatives.

-

No Maintenance: Once installed, these bars do not require any maintenance, providing a hassle-free waterproofing solution.

-

Adaptability: The bars are flexible and can adjust to slight movements in the concrete, ensuring continuous sealing even in shifting conditions.

Benefits Over Other Sealing Methods:

-

Self-Sealing: Unlike some traditional sealants or membranes that require external activation or periodic maintenance, bentonite bars expand automatically when exposed to water, making them a reliable choice for fluctuating water levels or pressure.

-

Effective in Dynamic Conditions: These bars perform well in structures where water pressure may vary, ensuring a consistent and durable seal, even under challenging conditions.

Installation Tips:

-

Positioning the Bar: Ensure the bar is placed properly in the joint or crack, typically in the formwork before the concrete pour. Its important that the bar is not disturbed during concrete placement to ensure a secure seal.

-

Correct Sizing: Ensure the 20mm x 25mm bar fits the width and thickness of the joint or crack. If the joint is larger, a bigger bar might be required to maintain effective sealing.

-

Preventing Drying Out Before Installation: Bentonite bars should be kept moist before installation, as prolonged exposure to dry conditions may reduce their swelling capacity.

-

Joining Multiple Bars: When multiple sections are required, the bars should be joined using a proper connection technique, ensuring no gaps are left between them. Typically, overlaps or sealed joints are used to prevent water from bypassing the bars.

Would you like more information on installation techniques, or how to determine the right size for your project?

Exceptional Water Swellability

This Bentonite Swellable Bar boasts a remarkable expansion ratio of up to 300% upon water contact, providing a reliable watertight seal in construction and infrastructure projects. The high absorption rate and excellent retention of structure after swelling make it ideal for critical waterproofing applications.

Robust and Chemical-Resistant

Designed for tough environments, the bar exhibits strong compression strength and withstands medium to high hardness. Its chemical resistance to acids and alkalis commonly found in concrete extends its longevity, ensuring durable performance for years.

User-Friendly Customization and Installation

Available in customizable lengths, the smooth-finished Bentonite Swellable Bar simplifies installation-just place it directly into concrete joints or construction gaps. Suitable for a wide range of professionals including dealers, fabricators, and wholesalers in India.

FAQ's of Premium Quality Bentonite Water Swellable Bar 20x25mm:

Q: How should the Bentonite Water Swellable Bar be installed in a construction project?

A: The bar is designed for straightforward installation. Simply place it directly into concrete joints or construction gaps before concrete pouring or sealing. It will expand upon contact with water, forming a waterproof barrier.Q: What makes the Bentonite Swellable Bar effective for waterproofing?

A: Its premium Bentonite material allows the bar to expand up to 300% upon water contact. This robust swelling capability, combined with high water absorption and durable compression strength, ensures reliable sealing against leaks in concrete structures.Q: When is the ideal stage to use this swellable bar during construction?

A: Install the bar prior to pouring concrete or before sealing construction gaps. Early placement ensures that, upon water exposure, the bar creates a secure waterproof barrier as the structure cures.Q: Where can this product be used for optimal results?

A: It is ideal for waterproofing requirements in tunnels, basements, concrete joints, and other construction settings susceptible to water ingress, particularly in civil engineering and structural projects across India.Q: What is the benefit of choosing a customizable length for my project?

A: Customizable length ensures the bar fits perfectly within the specific joints or gaps of your project, preventing waste and increasing installation efficiency, leading to a more effective waterproofing solution.Q: How does the bar maintain its effectiveness in varying temperatures or chemical environments?

A: Engineered to operate in temperatures ranging from -30C to +80C and resistant to common acids and alkalis present in concrete, the bar maintains its structure, expansion, and sealing ability under diverse conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PVC Water Bar Category

Pvc water stopper

Price 90.00 INR / Meter

Minimum Order Quantity : 1 Meter

Feature : Smooth Surface

Application : Pvc water stopper

Thickness : 6 Millimeter (mm)

Material : PVC Rubber

Water Swellble Bar 20 x 20 mm

Price 300.00 INR / Meter

Minimum Order Quantity : 1 Meter

Feature : Smooth Surface

Application : Industrial

Thickness : 20 Millimeter (mm)

Premium Quality Bentonite Water Swellable Bar 20x10mm

Price 192.0 INR / Meter

Minimum Order Quantity : 1 Meter

Feature : Other, SelfSwelling, Waterstop, Premium Quality

Application : Waterproofing Joints, Construction Joints, Concrete Structures

Thickness : 10 mm

Material : Sodium Bentonite with Rubber Mix

Hydrofilic Water Swellable Bar 25x20mm

Price 324.00 INR / Meter

Minimum Order Quantity : 1 Meter

Feature : Smooth Surface

Application : Industrial

Thickness : 10 Millimeter (mm)

Material : PVC Rubber

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free