Porous Rubber Hose

Price 90 INR/ Meter

Porous Rubber Hose Specification

- Product Type

- Rubber hose

- Color

- Black

Porous Rubber Hose Trade Information

- Minimum Order Quantity

- 100 Meter

- Payment Terms

- Cash Against Delivery (CAD)

- Supply Ability

- 1000 Per Week

- Delivery Time

- 7 Years

- Sample Available

- Yes

- Packaging Details

- Standard packing

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001 2015

About Porous Rubber Hose

Porous pipes, also known as porous hoses or porous tubes, are specialized pipes with permeable walls that allow fluids (liquids or gases) to pass through the walls over their entire length. The porous nature of these pipes is achieved through the use of materials or manufacturing techniques that create openings or pores in the pipe wall. These pipes are used in various applications for the controlled release, distribution, or filtration of fluids. Here are some key points about porous pipes:

1. Materials

- Ceramics Porous ceramic materials are often used to manufacture porous pipes. These ceramics can be engineered to have specific pore sizes and distributions.

- Plastics Some porous pipes are made from plastic materials with permeable structures. The plastic can be modified to create a porous network.

2. Applications

- Irrigation Porous pipes are commonly used in drip irrigation systems. They allow water to seep through the pipe walls, providing a controlled and efficient method of watering plants.

- Wastewater Treatment Porous pipes can be used in wastewater treatment systems to release treated water into the soil, promoting filtration and natural purification.

- Chemical and Gas Delivery In certain industries, porous pipes are employed to deliver chemicals or gases in a controlled manner.

3. Drip Irrigation

- Watering Efficiency In agriculture, porous pipes are used to efficiently deliver water directly to the root zones of plants. This reduces water wastage and minimizes evaporation.

- Even Distribution The porous structure of the pipe ensures an even distribution of water along its length.

4. Filtration

- Soil and Water Filtration Porous pipes can be buried in the ground to facilitate the natural filtration of water and soil. They allow water to percolate through the pipe walls, removing impurities in the process.

5. Air Distribution

- Aeration Systems Porous pipes can be used in aeration systems for aquariums or wastewater treatment. They release air in the form of fine bubbles, promoting oxygen transfer in water.

6. Pore Size and Distribution

- Controlled Permeability The design of porous pipes involves controlling the size and distribution of the pores to achieve the desired permeability for a specific application.

7. Maintenance

- Cleaning Depending on the application, porous pipes may require periodic cleaning to prevent clogging of the pores by debris or contaminants.

The selection of a porous pipe depends on the specific requirements of the application, including the type of fluid, desired flow rate, and the characteristics of the surrounding environment. It's essential to consider factors such as pore size, material compatibility, and the potential for clogging when choosing porous pipes for a particular use case.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Rubber Hoses Category

Cement Feeding Rubber Hose

Price 1800 INR / Meter

Minimum Order Quantity : 100

Material : Rubber

Shape : Round

Medium : Air

Hardness : 60 to 65 Shore A

Rubber Hose Carbon Free Hose pipe

Price 1100.0 INR / Meter

Minimum Order Quantity : 1 Meter

Material : Other, Synthetic Rubber

Shape : Round

Medium : Other, Electric cable, Water, Noncorrosive fluids

Hardness : 605 Shore A

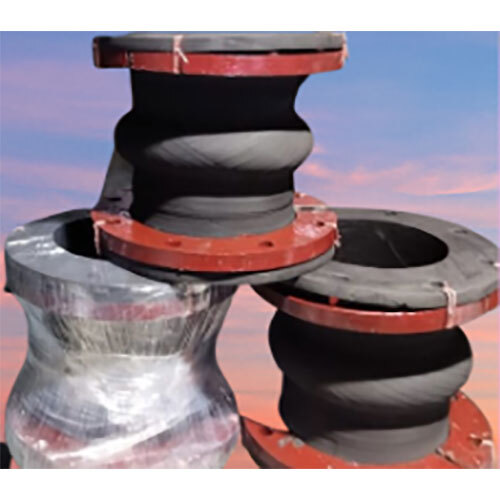

Rubber Expansion Joint Bellow

Price 8000.0 INR

Minimum Order Quantity : 1

Material : Other, High Grade Rubber

Shape : Round Bellow

Medium : Other, Water, Oil, Mild Chemicals

Hardness : 6365 Shore A

BSP Threated Nipple Rubber Hose

Price 1800.00 INR / Meter

Minimum Order Quantity : 1 Meter

Material : Rubber

Shape : Round

Medium : High Water Content Liquid

Hardness : Medium

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free